A Self-curling Transformer with Partial Overheating

A local overheating and transformer technology, applied in the field of transformers, can solve the problems of high temperature, high aging speed of heat dissipation scales, uneven local temperature distribution, etc., to achieve stable curling shape, good early warning effect, and avoid high temperature aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

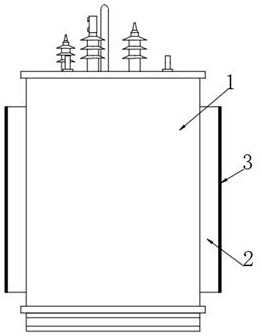

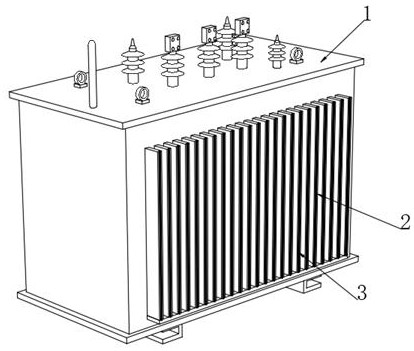

[0043] see Figure 1-2 , a local overheated self-winding transformer, including a transformer body 1, the outer end of the transformer body 1 is connected with a plurality of uniformly distributed heat dissipation scales 2, and fixed-point optical variable patches 3 are attached to the end faces of the heat dissipation scales 2 towards the outside.

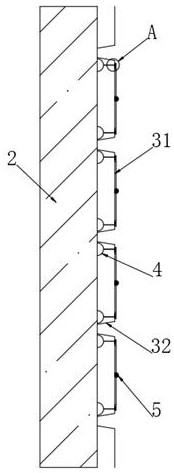

[0044] see image 3 and Figure 7 The fixed-point optical variable patch 3 includes a porous flat section 31 and a plurality of porous concave sections 32 respectively connected between two adjacent porous flat sections 31, the porous concave section 32 is bonded to the surface of the heat dissipation scale 2, and the porous flat section 31 The end facing outward is fixedly connected with the self-rolling light sheet 5, and the end of the porous flat section 31 facing the heat dissipation scale 2 is fixedly connected with a pair of early warning posts 4, and the two early warning posts 4 are connected to the two ends of the self-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com