Lithium battery top cover assembly and secondary battery

A lithium battery and top cover technology, which is applied to battery pack components, electrical components, circuits, etc., can solve the problem of poor liquid sealing inside the secondary battery, reducing the reliability of the secondary battery, and disconnecting the pole from the top cover plate. and other problems, to achieve the effect of increasing the bonding stability, improving the stability and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

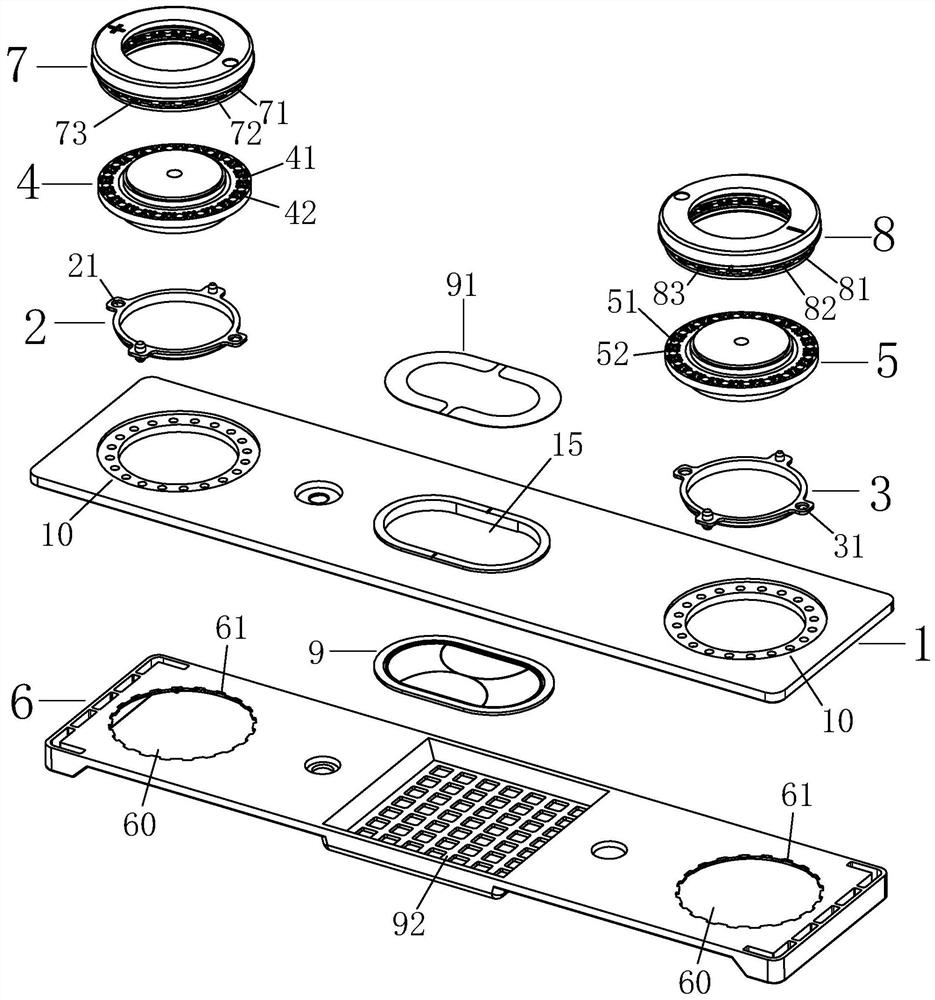

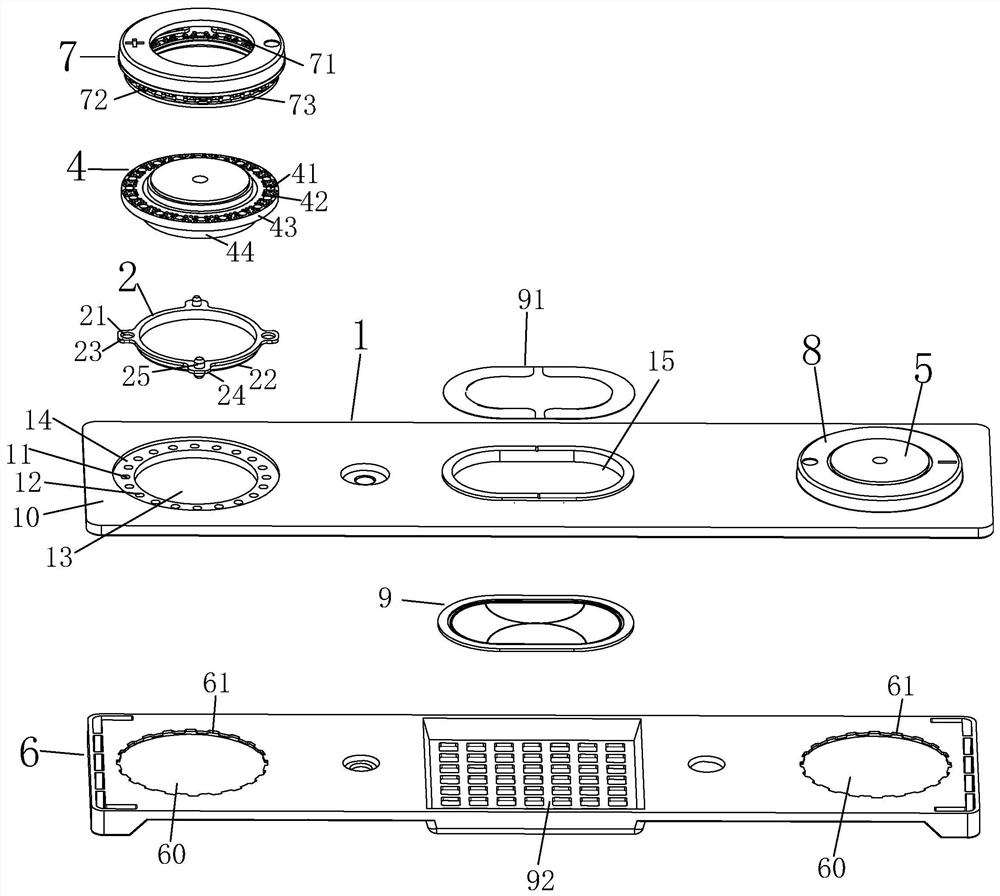

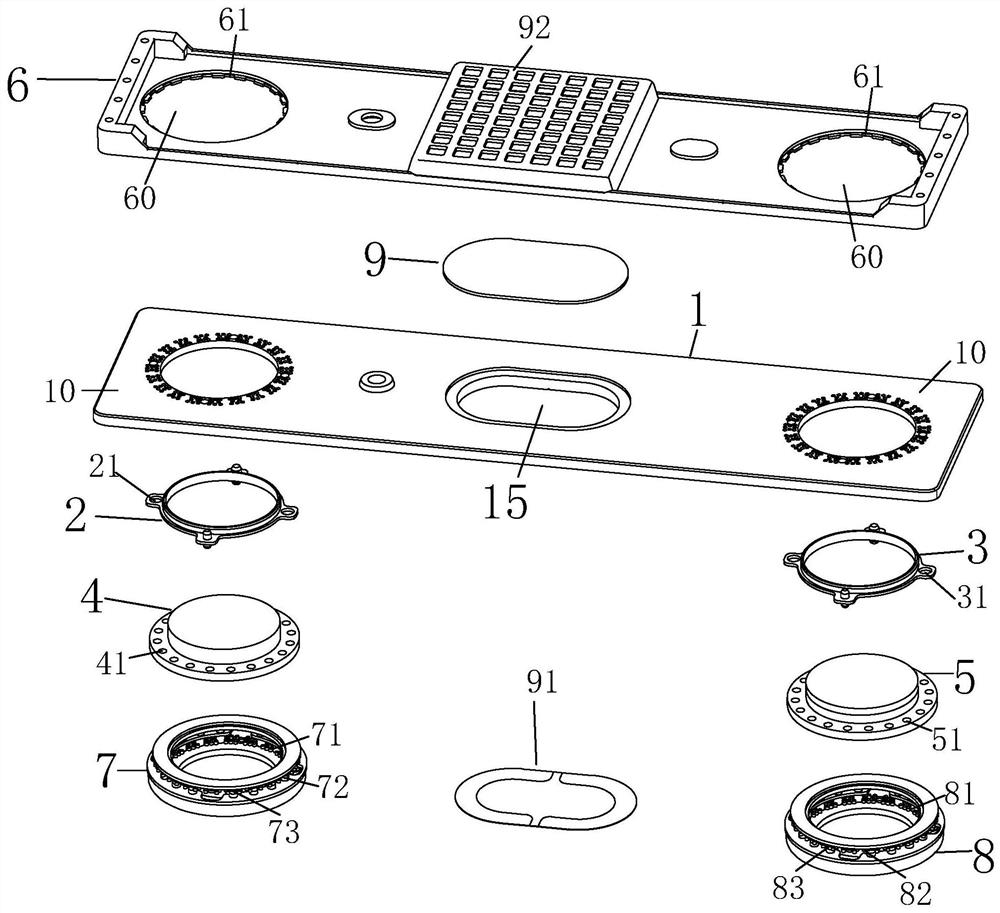

[0055] Please refer to Figure 1 to Figure 15 , an embodiment of the present invention provides a lithium battery top cover assembly, including:

[0056] The top cover plate 1 is formed with several top cover plate injection molding via holes 11 and several top cover plate bite pattern grooves 12, such as Figure 11 to Figure 14 shown;

[0057] The first seal 2 and the second seal 3 are both arranged on the top cover plate 1, and the first seal 2 and the second seal 3 are respectively formed with numbers corresponding to the injection molding holes 11 of the top cover plate. Injection molding via holes (21, 31) of a seal, such as Figure 1 to Figure 3 shown;

[0058] The first electrode terminal 4 and the second electrode terminal 5, the first electrode terminal 4 is arranged on the first sealing member 2, the second electrode terminal 5 is arranged on the second sealing member 3, and on the first electrode terminal 4 Several terminal injection molding via holes (41, 51) c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com