Rapid pin dismounting and mounting mechanism, dismounting and mounting tool and dismounting and mounting method

A pin shaft and fast technology, applied in the field of pin shafts, can solve problems such as difficult pin shaft assembly, achieve the effects of improving work efficiency, strong flexibility, and reducing the risk of bolt loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

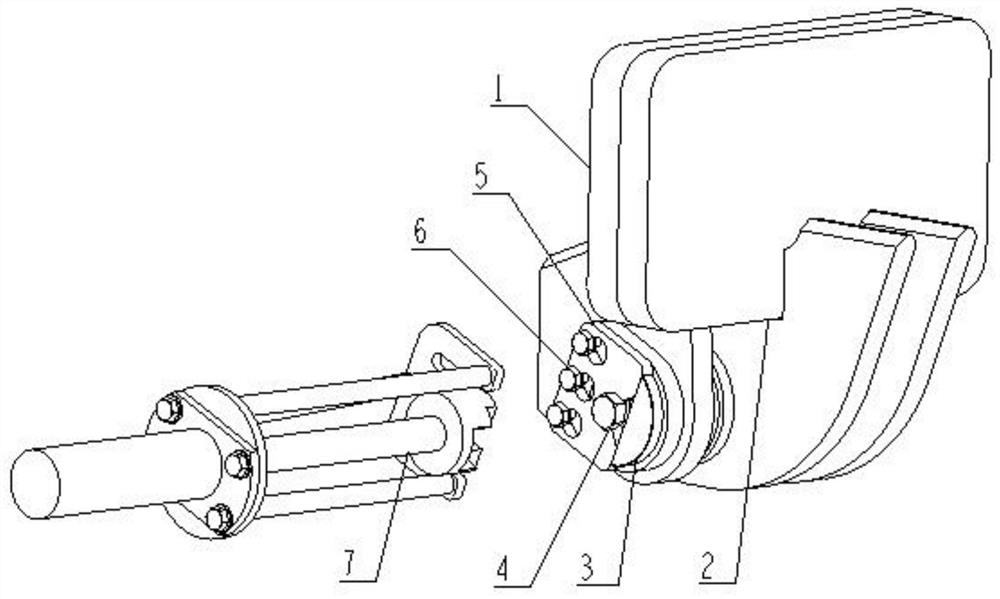

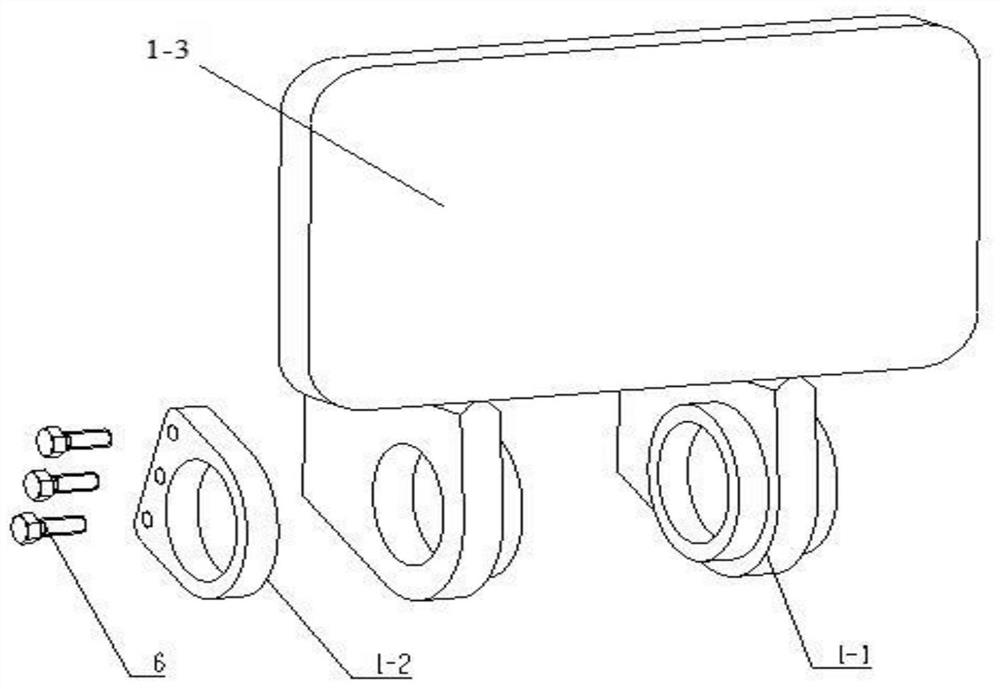

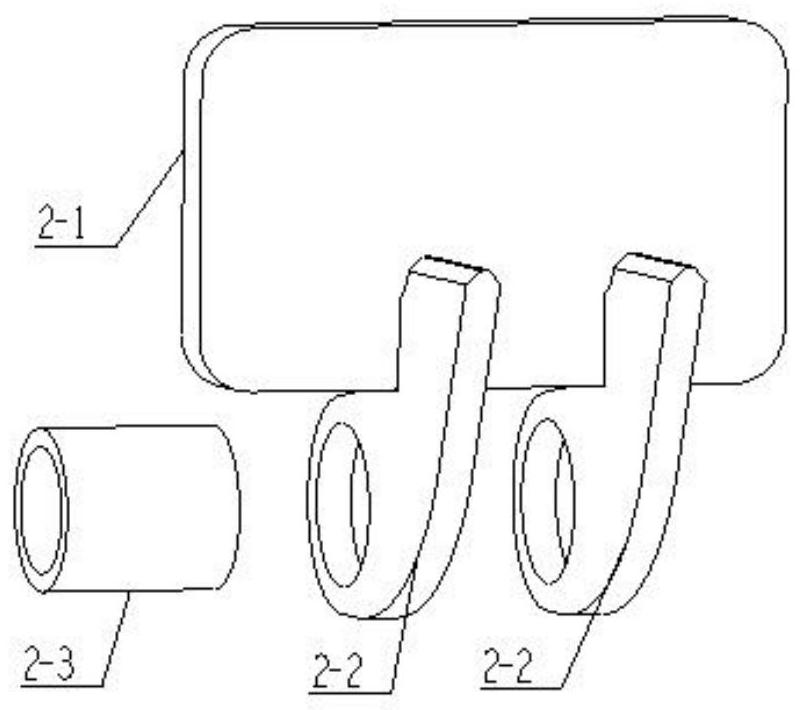

[0043] like Figure 1-5 As shown, a quick disassembly and assembly pin mechanism includes a first base body 1, a second base body 2, and a pin shaft 3; the first base body 1 includes a first base plate 1-3, and a first connection for installing the pin shaft Seat 1-1, mounting plate 1-2; a plurality of first connection seats 1-1 are arranged side by side on the side of the first substrate 1, and the mounting plate 1-2 is connected to the first connection at the end of the first substrate 1 Seat 1-1; the first connection seat 1-1 is provided with a pin hole for assembling the pin shaft 3; the mounting plate 1-2 is provided with a through hole for the pin shaft to pass through and a thread connected with the second bolt hole; the second base body 2 includes a second base plate 2-1, a second connecting seat 2-2 for installing a pin shaft, and a pin shaft ring 2-3; one side of the second base plate 2-1 is arranged side by side A plurality of second connecting seats 2-2; the pin r...

Embodiment 2

[0047] Such as Figure 6-8 As shown, a disassembly and assembly tool for quickly disassembling and assembling the pin shaft mechanism, the disassembly and assembly tool 7 includes a support frame 7-1, a hydraulic cylinder 7-2, and an assembly and disassembly block 7-3; A hydraulic cylinder 7-2 is provided; the hydraulic cylinder 7-2 drives the assembly and disassembly block 7-3 to move; the side wall of the assembly and disassembly block 7-3 is provided with a cavity 7-31, and the cavity 7-31 Used to limit the head of the first bolt 4; the bottom of the cavity 7-31 is provided with a first fixing groove 7-32 for accommodating the screw rod of the first bolt 4; the first fixing groove 7-32 is formed by the cavity Penetrate to the bottom of assembly and disassembly block 7-3.

[0048] The side wall of the assembly and disassembly block 7-3 is inwardly recessed and provided with a cut surface 7-33, and the opening of the first fixing groove 7-32 and the cavity 7-31 is arranged o...

Embodiment 3

[0051] A method for quickly disassembling and assembling a pin shaft mechanism, comprising:

[0052] Screw the first bolt 4 onto the pin shaft 3, and ensure that there is a gap between the head of the first bolt 4 and the surface of the pin shaft 3, and the gap has the same length as the first fixing groove 7-32;

[0053] Screw the second bolt 6 onto the mounting plate 1-2, and ensure that there is a gap between the head of the second bolt 6 and the mounting plate, which is the same thickness as the bottom plate 7-11;

[0054] arranging the pin shaft holes of the first base body 1 and the second base body 2 coaxially to the pre-assembly position;

[0055] The hydraulic cylinder 7-2 is in the retracted state, and the head of the first bolt 4 is set in the cavity 7-31 of the assembly and disassembly block 7-3, and the first fixing groove 7-32 blocks the head of the first bolt 4 ; The afterbody of the pin shaft 3 is in contact with the pin holes of the first base body 1 and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap