3D printing consumable structure and method

A technology of 3D printing and printing consumables, applied in the direction of 3D object support structure, additive processing, additive manufacturing, etc., to achieve the effect of simple structure, avoiding bubble problems, and easy consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

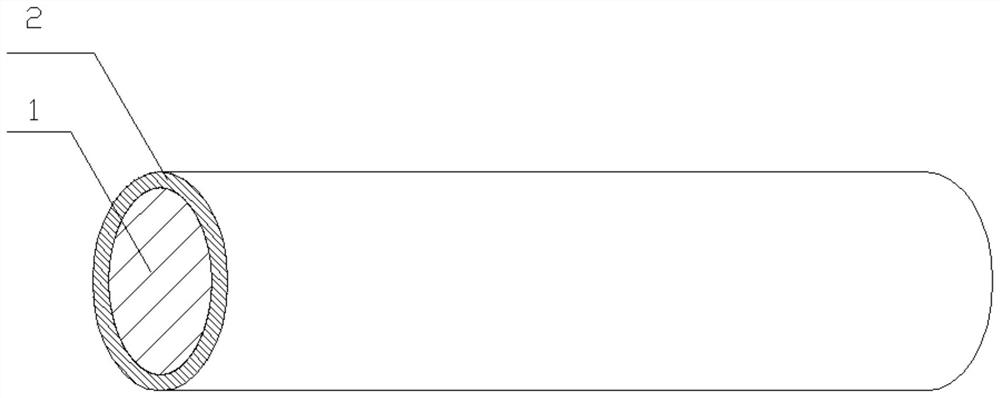

[0023] Such as figure 1 As shown, the structure of the 3D printing consumables of the present invention includes a main body 1 whose outer surface is wrapped with a waterproof material layer 2 .

[0024] The waterproof material layer 2 is a transparent waterproof material layer.

[0025] The waterproof material layer 2 is a waterproof material layer volatilized by heat.

[0026] The waterproof material layer 2 is a waterproof material layer made of powder.

[0027] The waterproof material layer 2 is a waterproof material layer made of oily material.

[0028] The method, which is applied to the 3D printing consumable structure, includes the following steps: wrapping a waterproof material layer 2 on the surface of the main body 1 .

[0029] The consumables are produced from the extruder, cooled by the cooling device, and then wound on the coil by the winding machine; the step of wrapping the waterproof material layer on the main body is completed after the consumables are ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com