Early deformation monitoring structure and method for cement concrete pavement

A cement concrete and deformation monitoring technology, applied in the directions of roads, roads, measuring devices, etc., can solve the problems of inability to accurately guide the construction of concrete on-site, large differences, inability to realize early-age disease early warning and prompting, etc., and achieve good industrialization. Prospects and the effect of improving operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

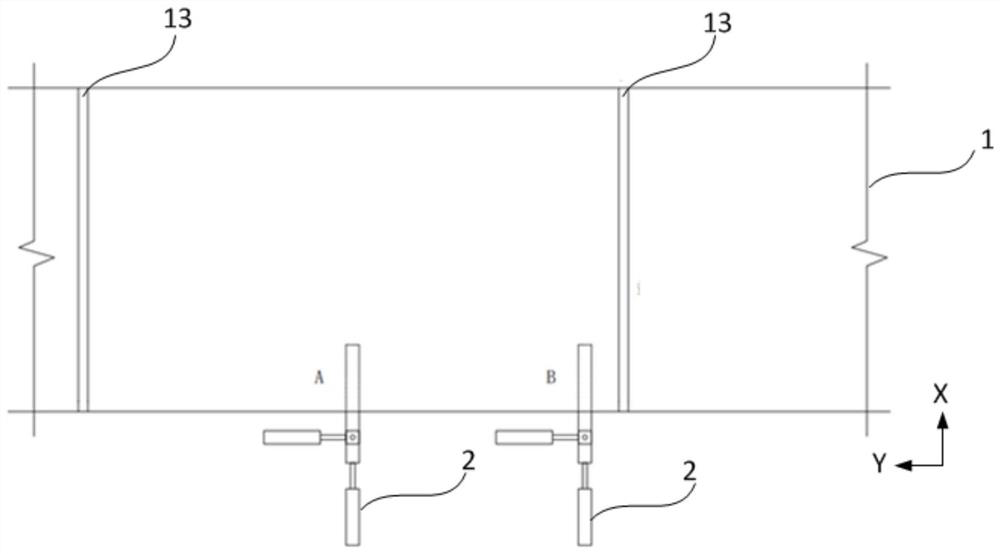

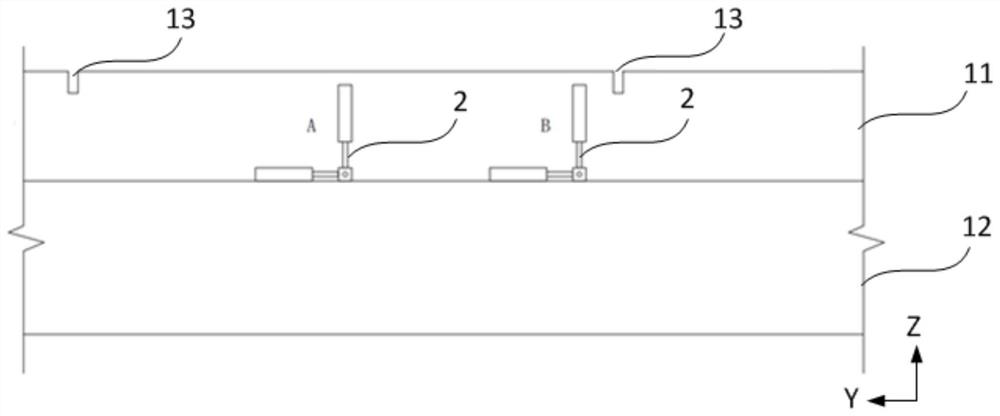

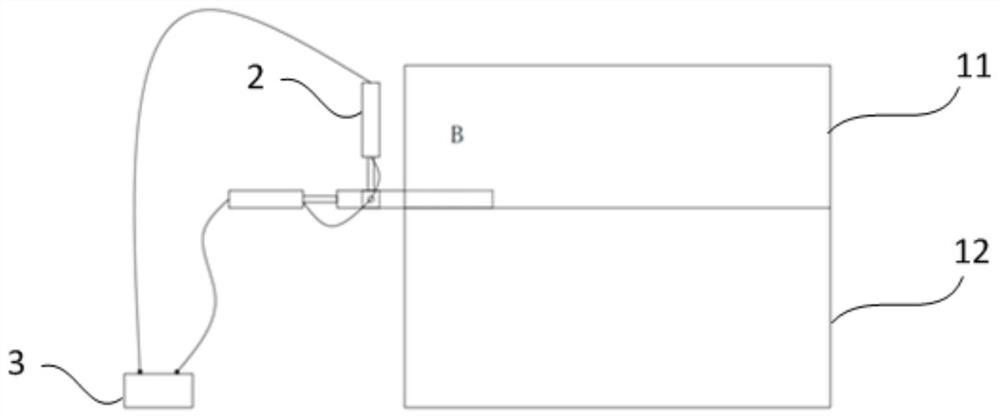

[0104] According to the construction drawing of the concrete road (road) surface slab, mark the position corresponding to the slit of the surface slab and the center of the slab on the base. The layout points A and B are respectively marked on the outer side of the road between the cuts of the near road surface and the middle of the two adjacent road surface cuts. The distance between B and the cuts is 5cm. Mark A1, A2, A3, B1, B2, and B3 at 15cm respectively as the preset hole positions of the steel column for the installation position of the three-axis deformation monitoring device.

[0105] Inorganic binder stabilized materials are used as the material of the concrete road (road) surface base, and the construction thickness is 20cm. After the construction and maintenance of the concrete road (road) surface base is completed, according to the pre-set installation position of the triaxial deformation monitoring device, the reinforcement column For the layout of the holes, use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com