Hydroelectric generating set group shafting vibration fault holographic identification method

A technology for shafting vibration and hydroelectric units, which is applied in hydroelectric power generation, testing of mechanical components, testing of machine/structural components, etc., can solve the problem of losing effective information and inability to accurately and effectively identify shafting vibration faults of hydropower groups , the accuracy of fault diagnosis cannot be guaranteed, etc., to achieve the effect of ensuring accuracy and comprehensiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

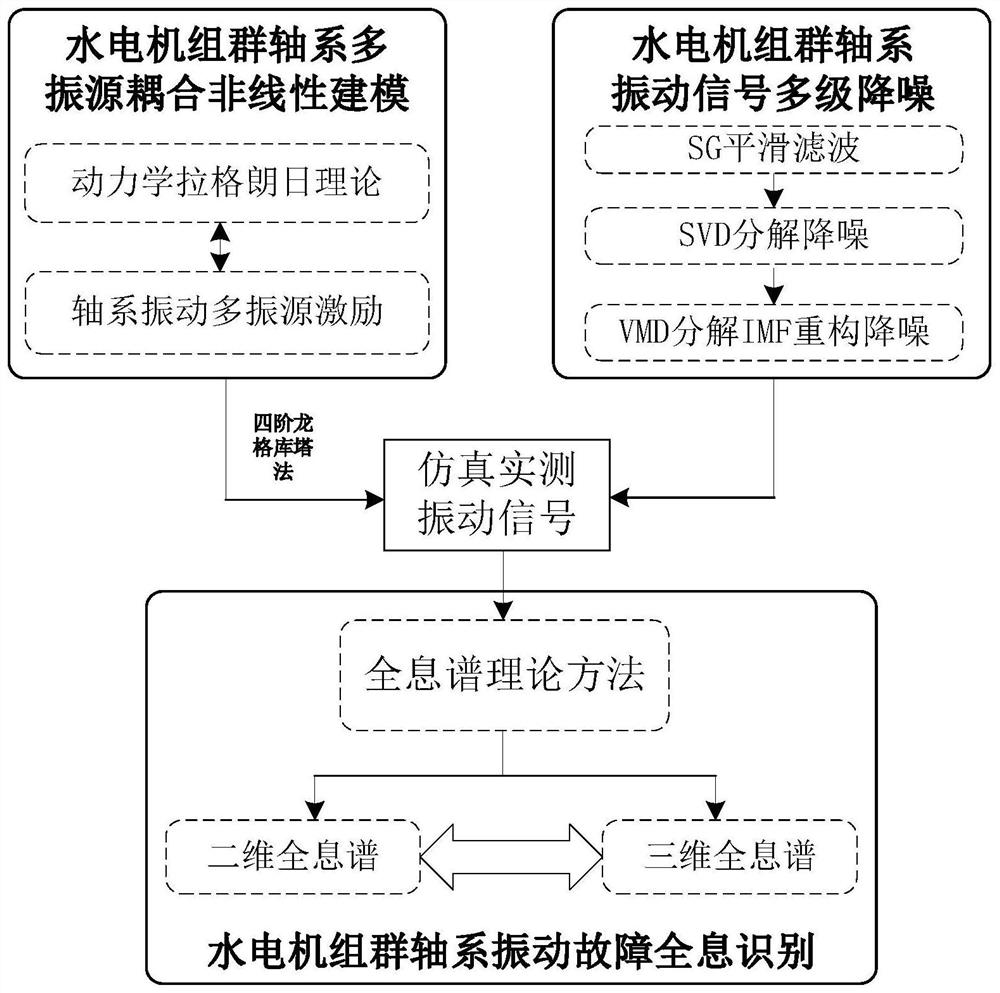

[0066] A holographic identification method for shafting vibration faults of hydropower groups, such as figure 2 shown, including:

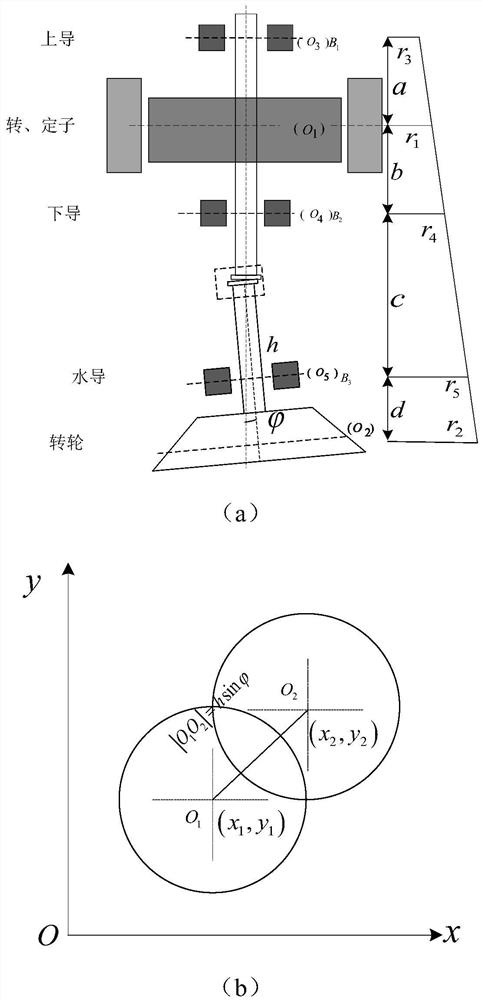

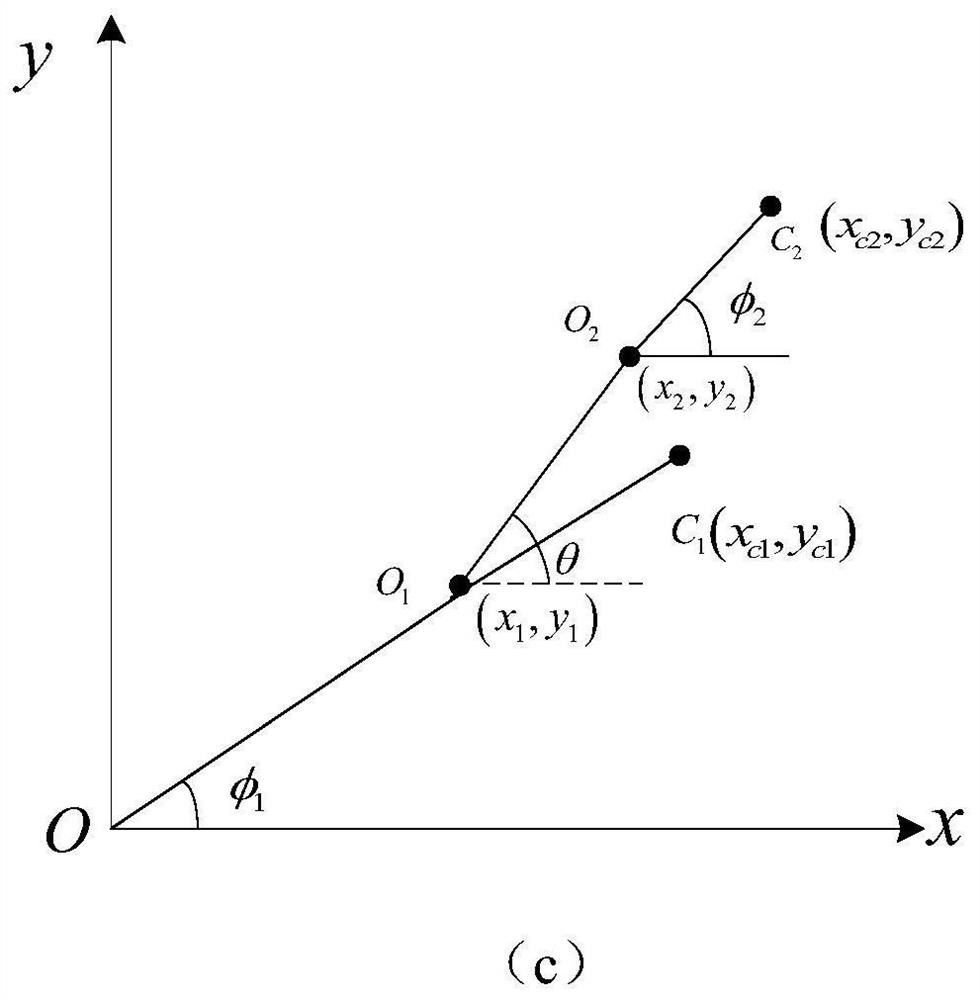

[0067] Fault analysis stage: take rotor-stator friction force, unbalanced magnetic pull force, seal excitation force, hydraulic unbalanced force, rotor bow-shaped turning force, runner bow-like turning force, oil film force and runner vortex belt eccentric force as external Excitation vibration source, based on the dynamic Lagrange theory to establish a nonlinear vibration model of the hydroelectric group, which is used to describe the vibration of the generator rotor and turbine runner in the hydroelectric group under the action of an external excitation vibration source; solve the nonlinear Vibration model, obtain the vibration simulation information of the generator rotor and the turbine runner, convert it into the vibration simulation information of the guide bearing in the hydropower group, solve its holographic spectrum, and analyze the cha...

Embodiment 2

[0132] A computer-readable storage medium, including a stored computer program; when the computer program is executed by a processor, the device where the computer-readable storage medium is located is controlled to execute the holographic identification method for shaft system vibration faults of hydropower groups provided in Embodiment 1 above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com