Down locking fabric for down jackets

A technology for down jackets and fabrics, which is applied in the field of down jackets and lock down fabrics. It can solve the problems of fabric bulges and deformation, fleece, and large thread holes, so as to prevent water bulges and improve toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

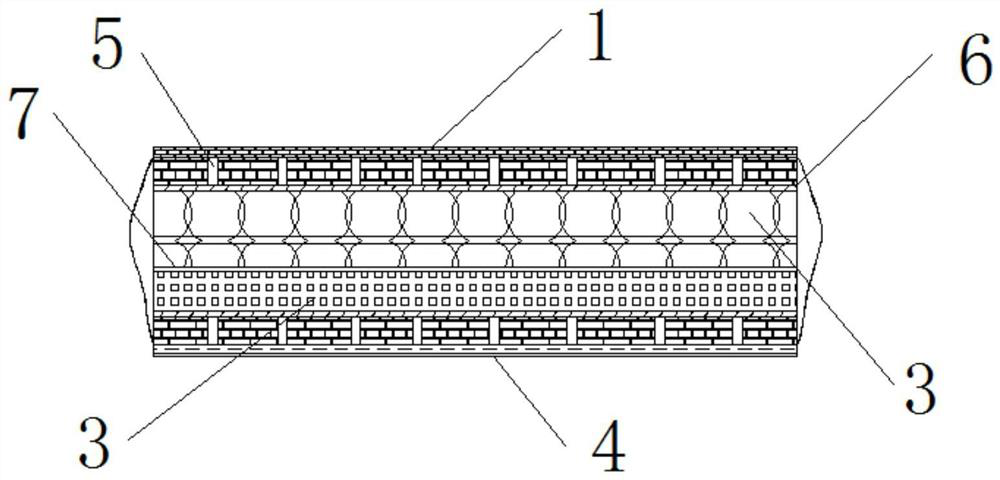

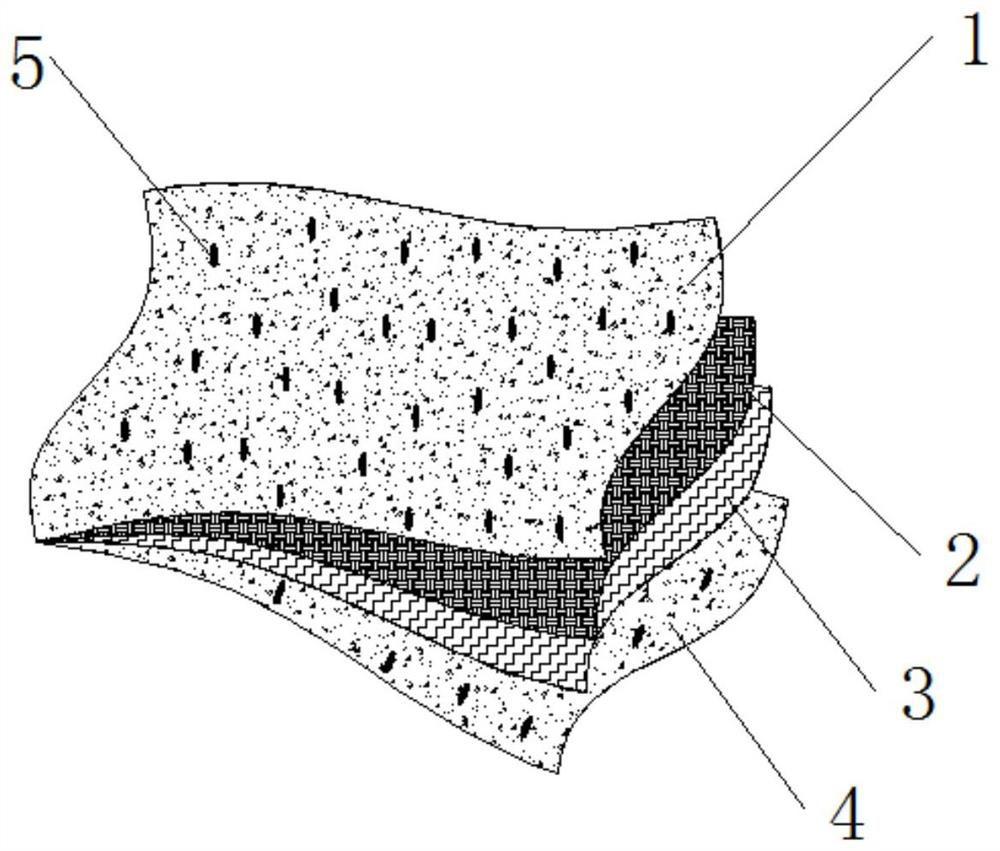

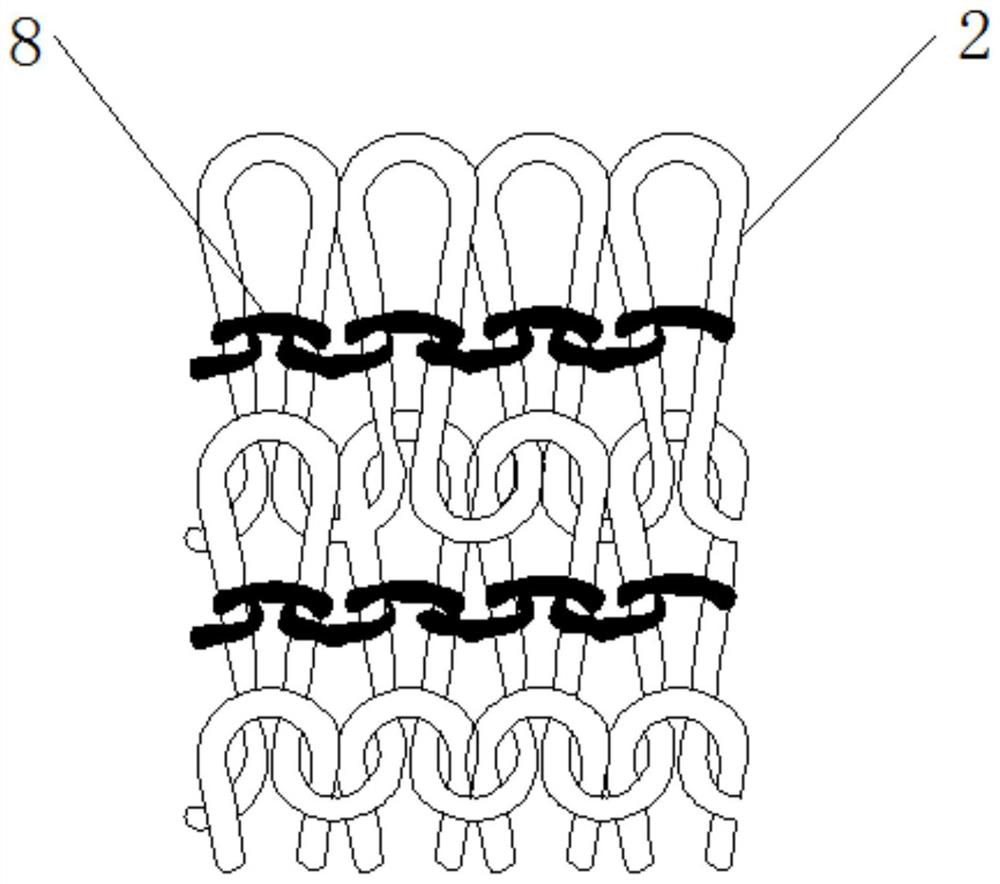

[0018] see Figure 1-3 As shown, a lock fleece fabric for down clothing is composed of surface fabric 1, fiber silk layer 2, antibacterial layer 3 and inner fabric 4 which are arranged from outside to inside. The wiring holes 5 are used for filling and sewing fabrics. The fiber filament layer 2 is located on the inner side of the surface layer fabric 1. The fiber filament layer 2 is divided into a mesh-like structure through the braided filament 8, and is closely attached to the outer layer fabric 1. And the net cover hole is staggered with the wire hole 5, the braided wire corresponds to the wire hole 5, the antibacterial layer 3 is positioned at the inner side of the fiber silk layer 2, the inner layer fabric 4 is positioned at the inner side of the antibacterial layer 3, and the inner layer fabric 4 is provided with Corresponding to the wiring holes 5 of the surface fabric 1; the outside of the surface fabric 1 is coated with a waterproof coating, and the inside is coated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com