Flat screen printing machine with automatic feeding function

An automatic feeding and printing machine technology, which is applied to screen printing machines, printing machines, rotary printing machines, etc., can solve the problems of high labor intensity and low work efficiency of the staff, and achieve cost saving, pollution reduction and use reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

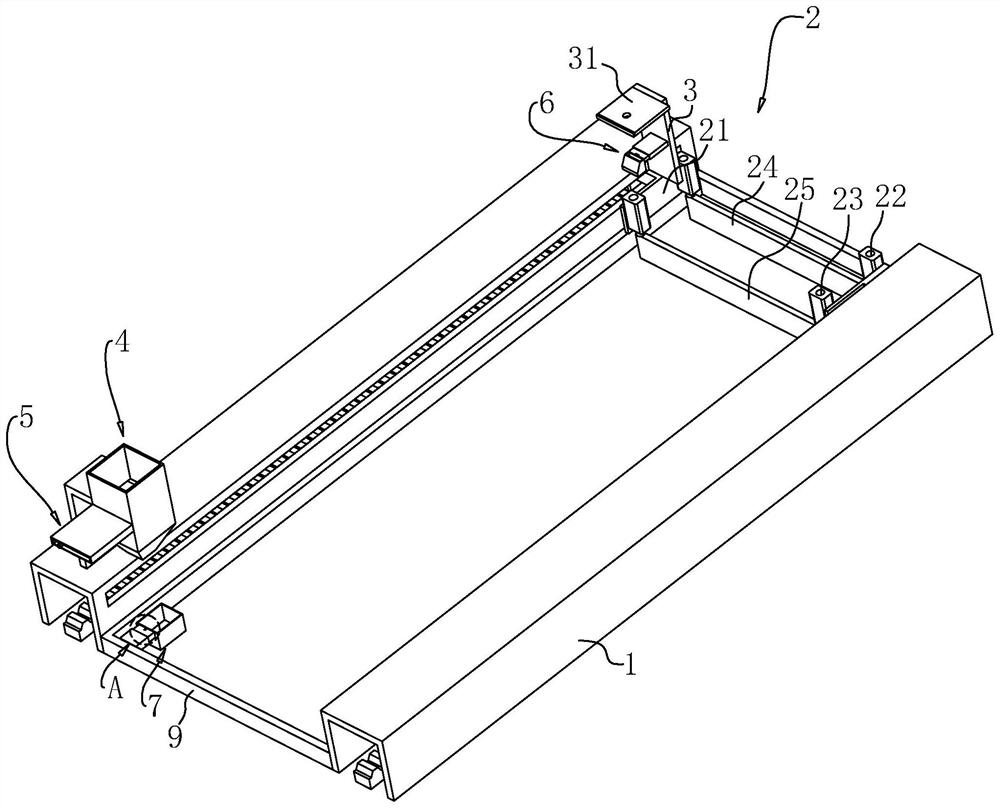

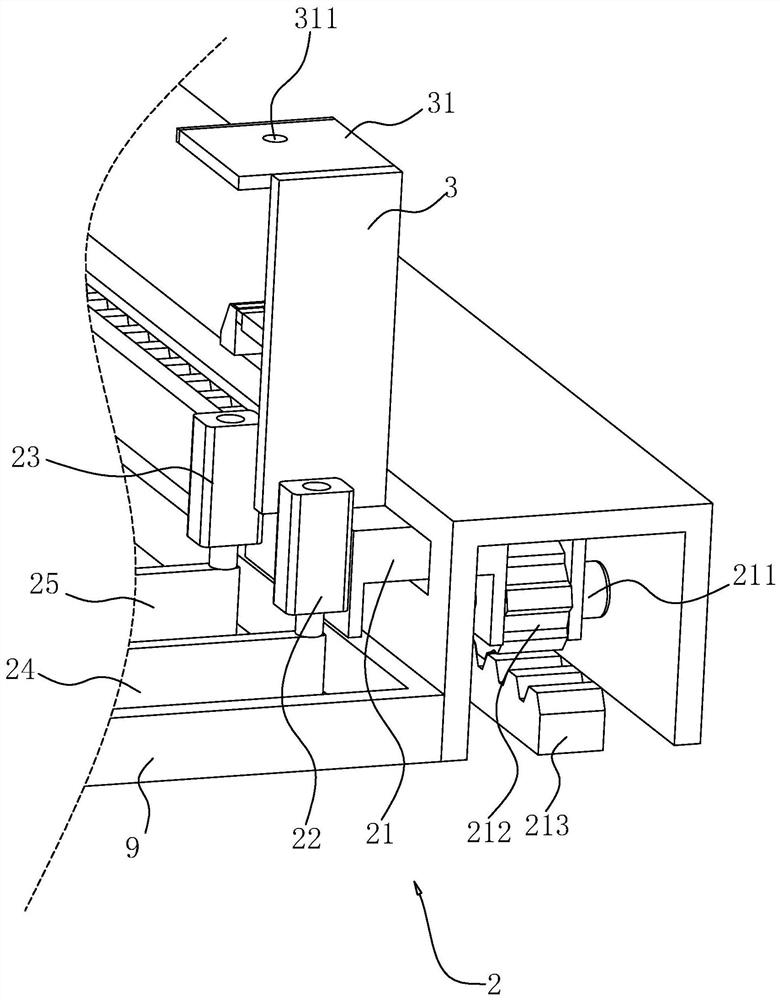

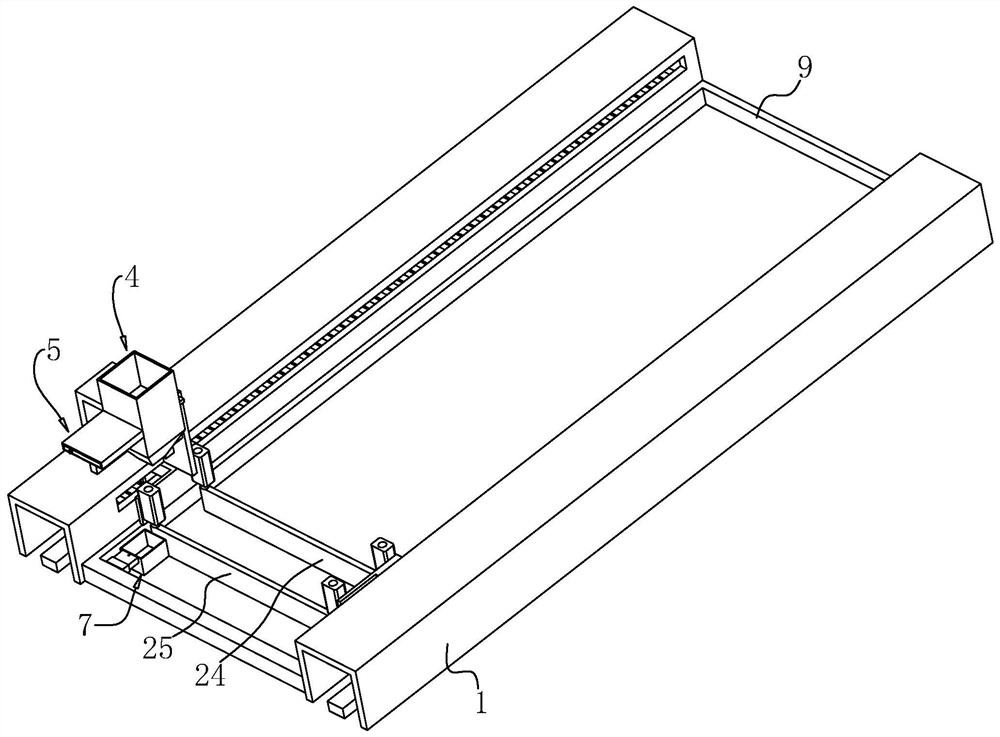

[0036] The following is attached Figure 1-6 The application is described in further detail.

[0037] The embodiment of the present application discloses a flat screen printing machine with automatic feeding function.

[0038] refer to figure 1 and figure 2 , the flat screen printing machine includes a flat screen printing machine frame 1 and a printing frame plate 9, the flat screen printing machine frame 1 is provided with a feeding assembly 2, and the feeding assembly 2 includes a knife block 21, the flat screen printing machine machine The frame 1 is provided with a drive motor 211 fixedly connected with the tool holder 21, the output shaft of the drive motor 211 is fixedly connected with a gear 212, the rotation axis of the gear 212 is horizontal, and a rack 213 is engaged with the gear 212 below, and the rack 213 is arranged horizontally , the rack 213 is relatively fixed to the frame 1 of the flat screen printing machine, the driving motor 211 reciprocatingly rotate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap