Pressure-sensitive label printing equipment and printing method

A label printing and equipment technology, applied in self-adhesive label printing equipment and printing fields, can solve problems such as poor practicability, achieve the effects of preventing printing blur and more stains, avoiding direct contact, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

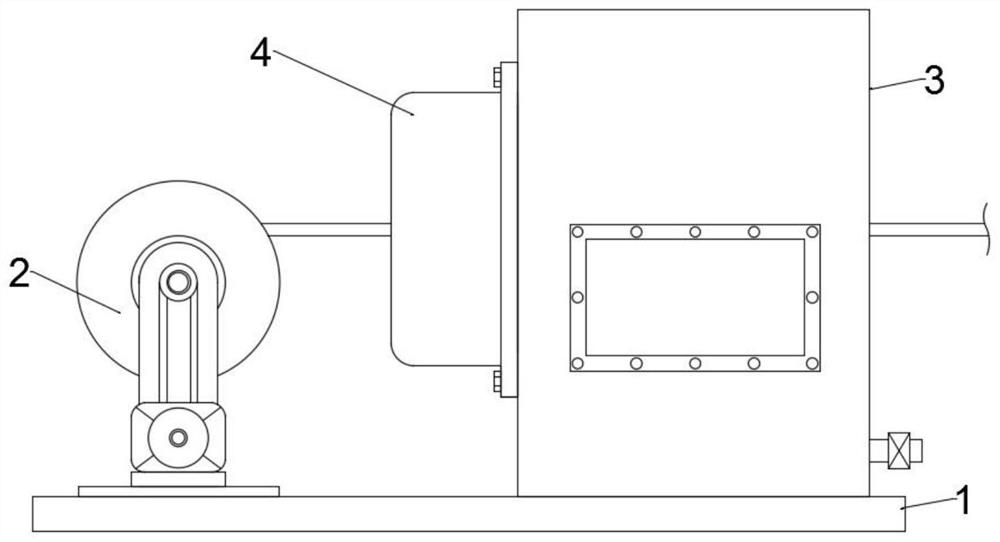

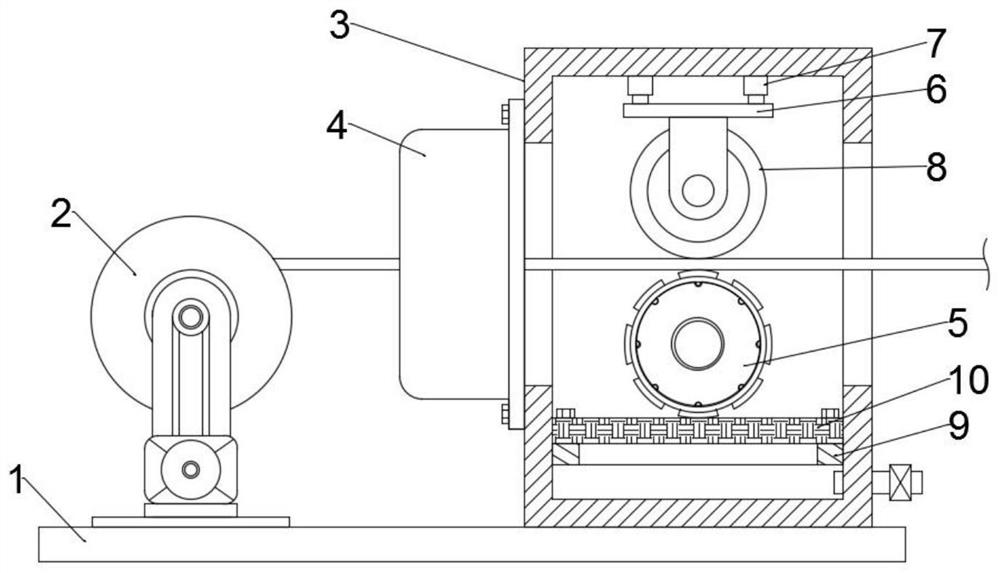

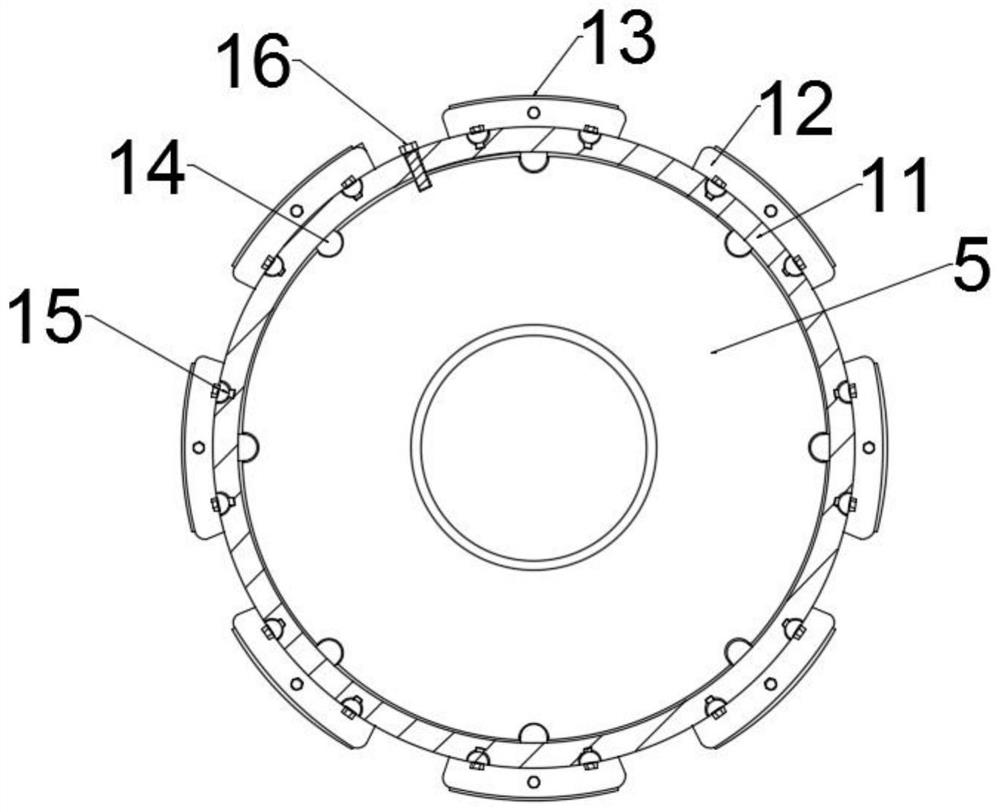

[0020] Example: see Figure 1-4 , a kind of self-adhesive label printing equipment among the present invention, comprises bottom plate 1, the winding machine 2 that is arranged on one side of the top surface of bottom plate 1, the printing box 3 that is arranged on the other side of bottom surface 1 top surface and is arranged on the printing box The dryer 4 on one side of the upper part of the printing box 3 is provided with through openings on both sides of the printing box 3. The feed port of the dryer 4 is connected to the through opening on one side of the printing box 3, and the bottom of the printing box 3 is filled with printing ink. The lower part on the inner wall of the rear end of the printing box 3 is provided with a printing assembly for self-adhesive label printing, and the inner top surface of the printing box 3 is provided with a pressing assembly for pressing the self-adhesive label. , it is convenient to carry out stable printing operation on self-adhesive l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com