Conveying and printing device for medicine bottle

A technology of printing device and conveying device, applied in printing, stamping and other directions, can solve the problems of inability to realize printing and transfer, single function, etc., and achieve the effects of precision guarantee, good stencil effect and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

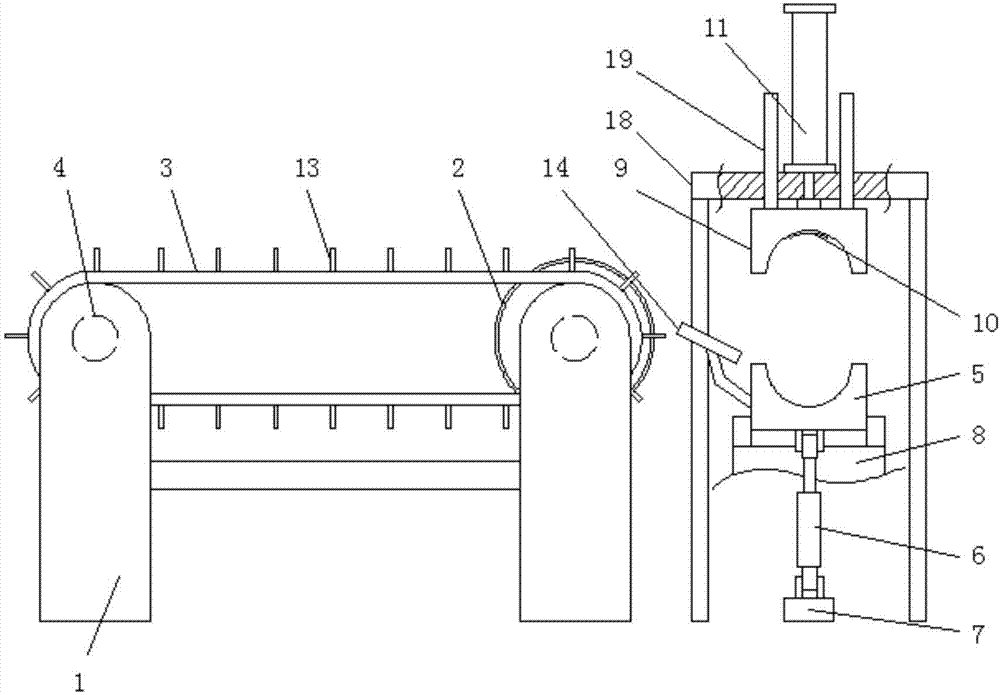

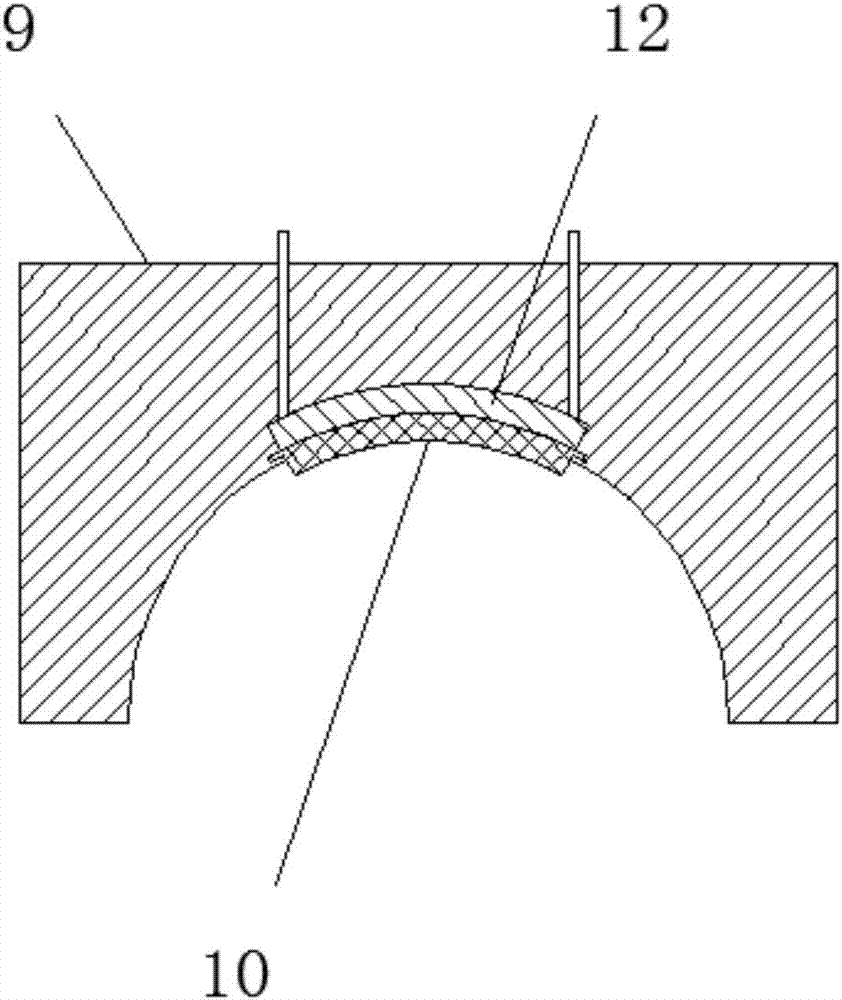

[0029] like Figure 1 to Figure 3 As shown, a medicine bottle conveying and printing device includes a conveying device, a turning device and a printing device, the turning device is located at the end of the conveying device, and the printing device is located just above the turning device;

[0030] The conveying device includes a conveying frame 1, a conveying motor 2 and a conveying belt 3, a conveying roller 4 is installed on the conveying frame 1, the conveying belt 3 is wound on the conveying roller shaft, and the conveying roller 4 is connected with the conveying motor 2, The conveying motor 2 adopts a servo motor, which is beneficial to realize the stepping motion of the medicine bottle;

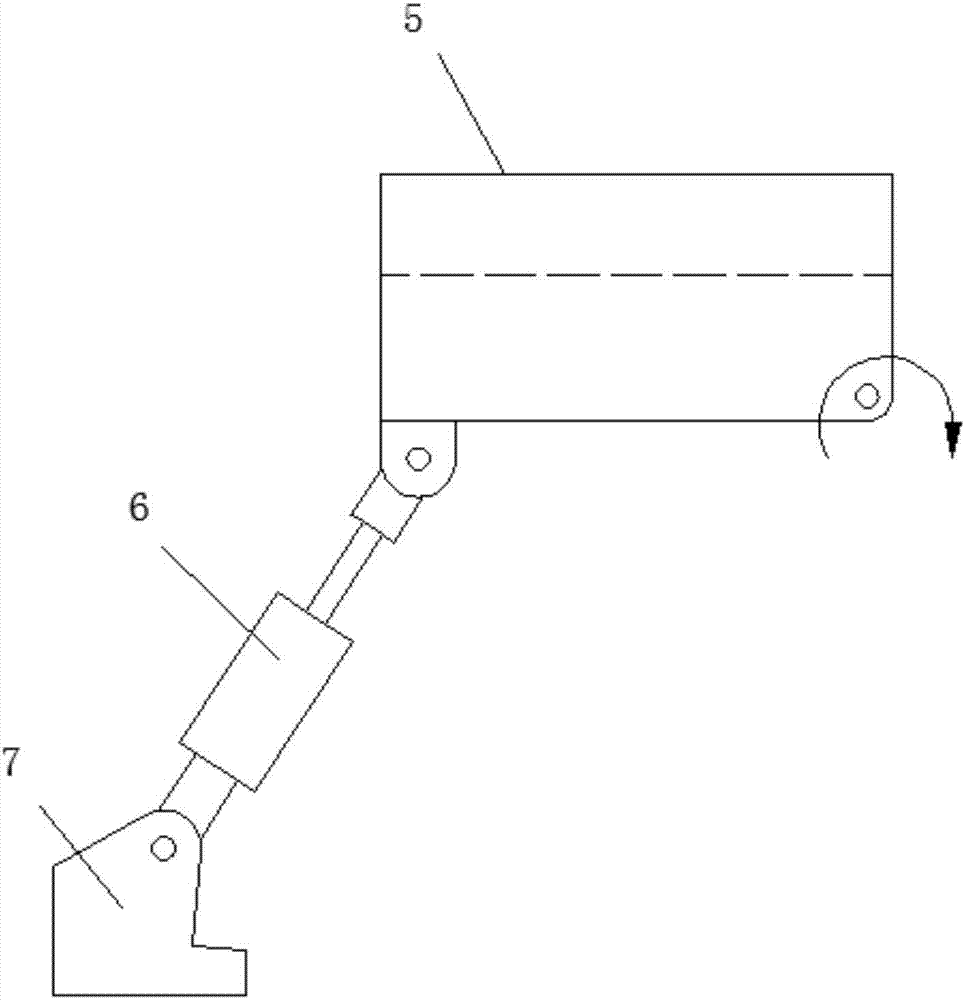

[0031] The flipping device includes a flipping seat 5, a flipping cylinder 6 and a cylinder base 7, one end of the flipping base 5 is hinged with a base 8, the other end of the flipping base 5 is hinged with the flipping cylinder 6, and the other end of the flipping cylinder 6 is hin...

Embodiment 2

[0038] like Figure 1 to Figure 3 As shown, a medicine bottle conveying and printing device includes a conveying device, a turning device and a printing device, the turning device is located at the end of the conveying device, and the printing device is located just above the turning device;

[0039] The conveying device includes a conveying frame 1, a conveying motor 2 and a conveying belt 3, a conveying roller 4 is installed on the conveying frame 1, the conveying belt 3 is wound on the conveying roller shaft, and the conveying roller 4 is connected with the conveying motor 2, The conveying motor 2 adopts a servo motor, which is beneficial to realize the stepping motion of the medicine bottle;

[0040] The flipping device includes a flipping seat 5, a flipping cylinder 6 and a cylinder base 7, one end of the flipping base 5 is hinged with a base 8, the other end of the flipping base 5 is hinged with the flipping cylinder 6, and the other end of the flipping cylinder 6 is hin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com