Modular building and assembling method for central control room unit, and ship

A technology of unit modules and assembly methods, which is applied to ships and other directions, can solve the problems of long dock period and difficulty in controlling the construction quality of centralized control rooms, and achieve the effect of shortening the dock cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

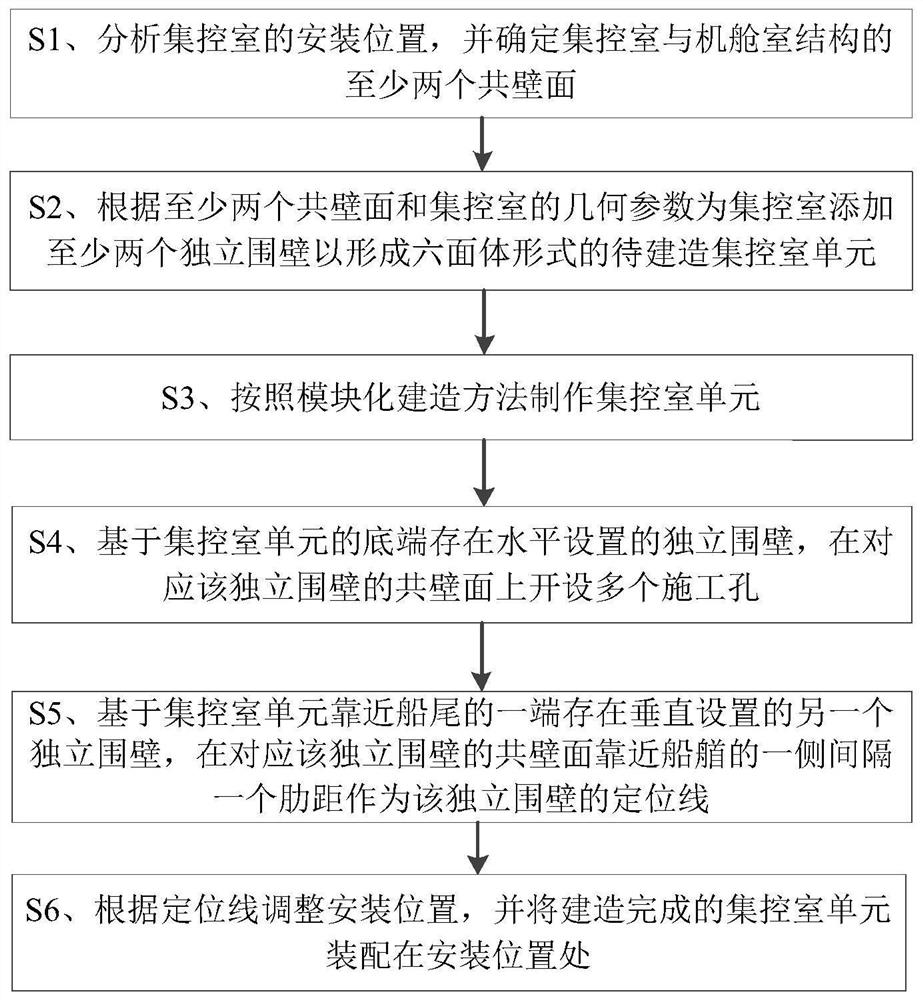

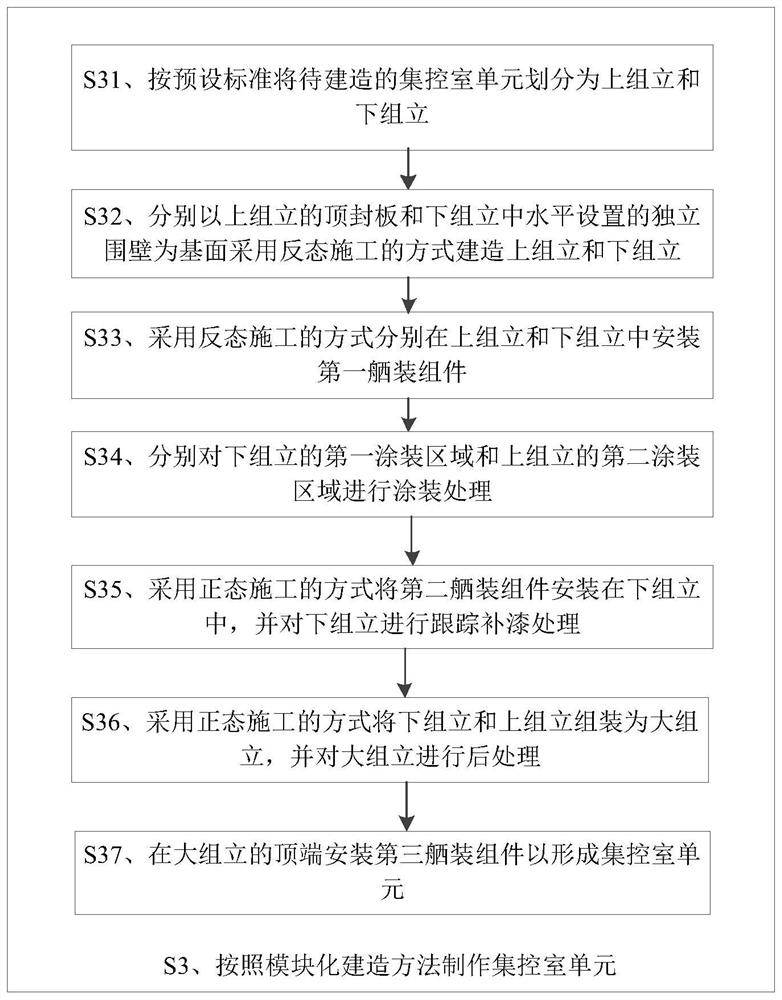

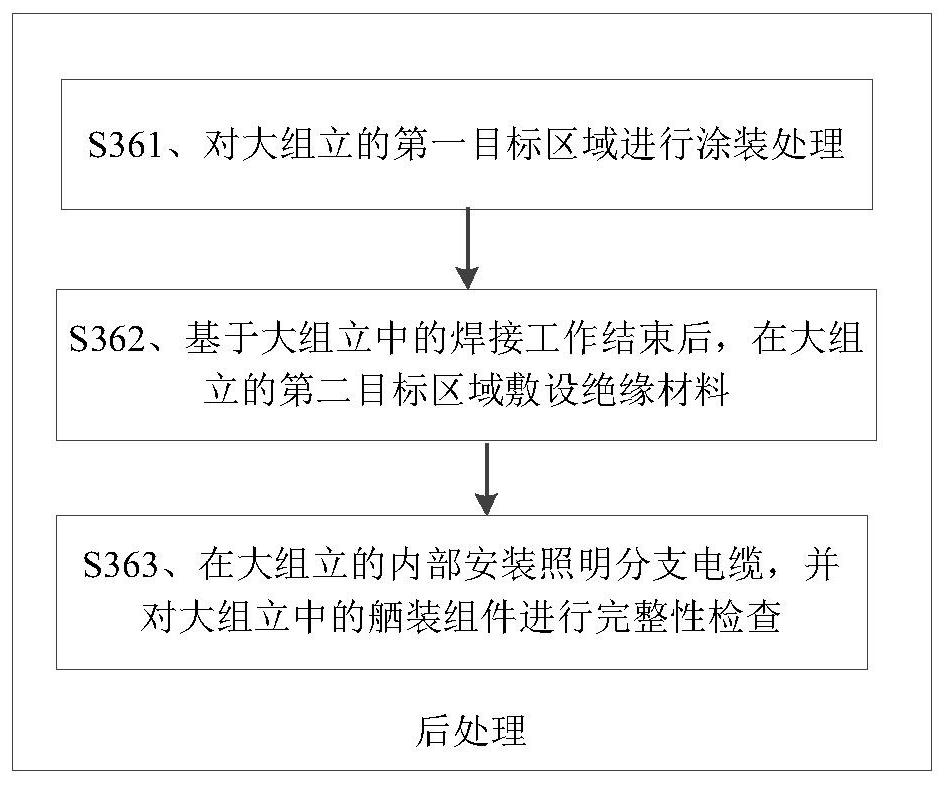

[0033] The present invention provides a modular construction and assembly method of central control room unit, please refer to Figure 1 to Figure 4 ,include:

[0034] S1. Analyze the installation location of the centralized control room, and determine at least two common wall surfaces between the centralized control room and the engine room structure;

[0035] S2. According to at least two common walls and the geometric parameters of the central control room, add at least two independent walls to the central control room to form a hexahedral central control room unit 2 to be built;

[0036] In some examples, see figure 1 , the central control room is arranged on the second deck of the engine room, and it has a common wall with the rear bulkhead of the engine room and the second deck of the engine room, so it cannot form a hexahedron structure by itself. The present invention aims at this situation, by adding two independent walls to avoid coplanarity with the cabin structur...

Embodiment approach 2

[0072] The present invention also provides a ship, including the centralized control room unit 2 constructed and assembled by adopting any one of the centralized control room unit 2 modular construction and assembly methods in the first embodiment. Those skilled in the art should understand that the ship in this embodiment has the same beneficial effect as the modular construction and assembly method of the central control room unit 2 in the first embodiment, and details will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com