Geological mineral product drilling rock core splitting sampler

A sampler and mineral technology, applied in the direction of sampling devices, etc., can solve the problems of not being able to adjust the space of the two enclosures in a large range, reducing the working environment of the sampler, and prone to a large amount of dust, so as to prevent re-lifting and strengthen clamping The effect of maintaining stability and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

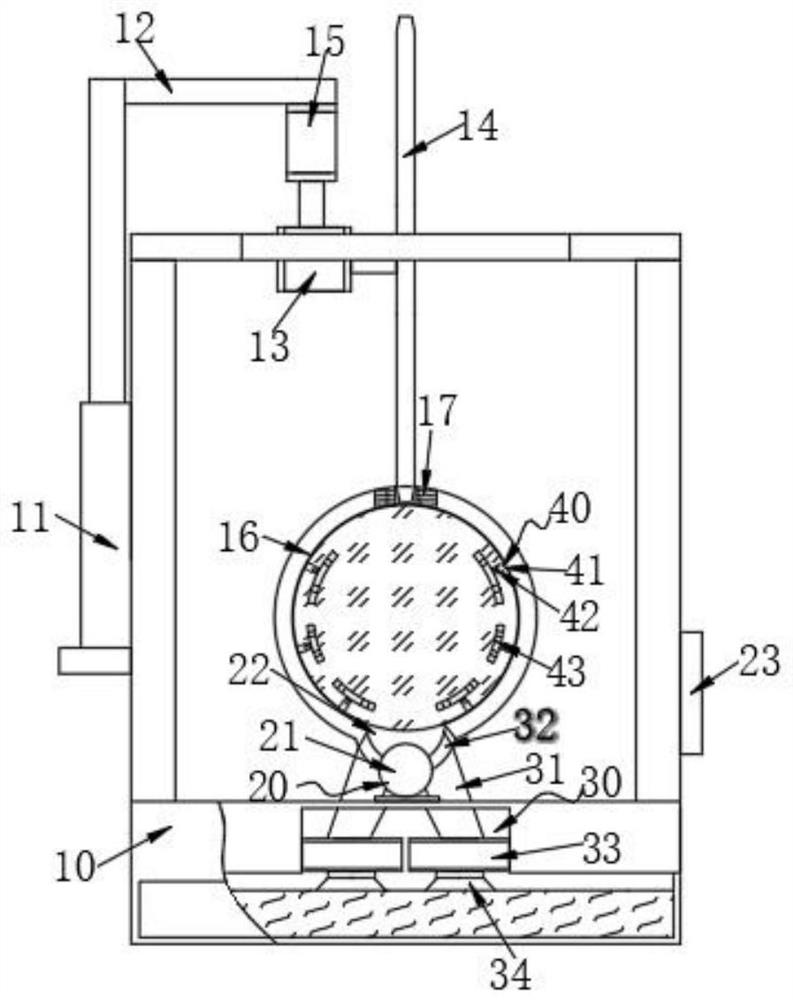

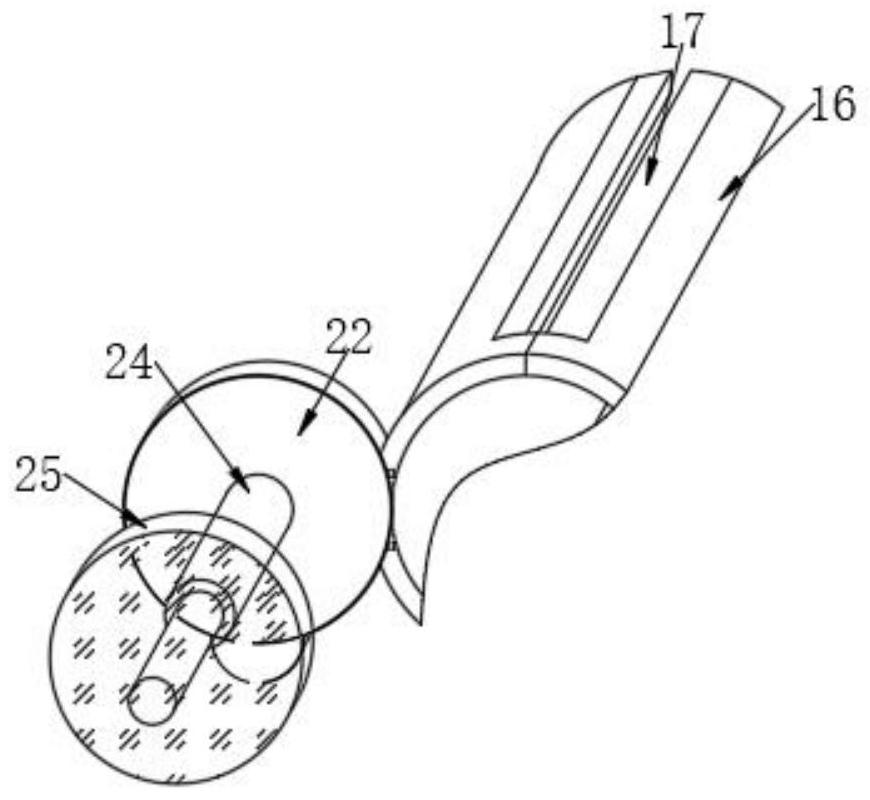

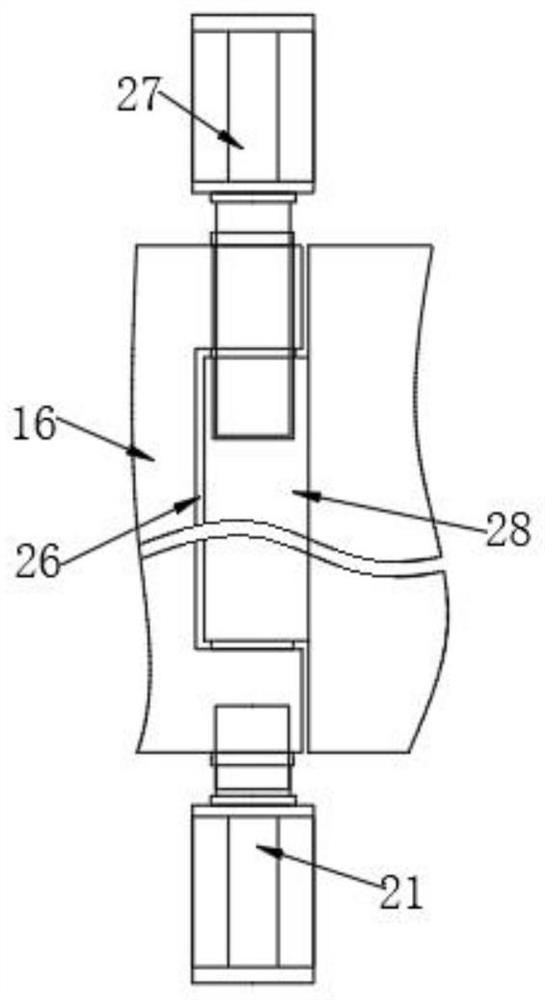

[0037] Such as figure 1 , figure 2 , image 3 and Figure 4 shown;

[0038] A geological and mineral drilling core splitting sampler, comprising a fixed platform 10, a cylinder 11 installed on the outer wall of the fixed platform 10, a fixed plate 12 is fixed on the telescopic end of the cylinder 11, and an electric push rod 15 is installed on the bottom surface of the fixed plate 12, The telescoping end of electric push rod 15 is fixed with first motor 13, and the output shaft of first motor 13 is equipped with cutter head 14, and the inner side wall upper surface of fixed table 10 is symmetrically rotated and is connected with coaming plate 16.

[0039] In this embodiment: the geological and mineral drilling core splitting sampler main body is made up of fixed table 10, cylinder 11, fixed plate 12, first motor 13, cutter head 14, electric push rod 15 and coaming plate 16, existing geological The main body of the mineral drilling core splitting sampler has the problem th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com