Leakage-proof burette, system and using method thereof

A burette and tube system technology, which is applied in the direction of chemical analysis by titration, can solve the problems that affect the accuracy and convenience of titration operation in chemical analysis, poor use of time, and poor sealing of joints, etc., to achieve good results. The effect of controlling the titration speed, convenient cleaning, and eliminating the problem of dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

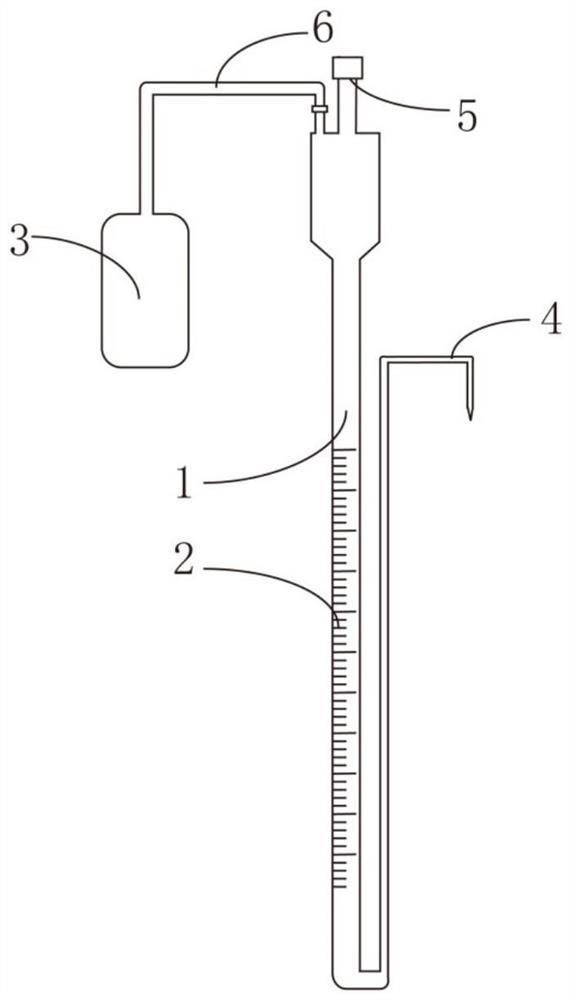

[0025] Such as figure 1 As shown, a leak-proof burette includes a burette body 1, a U-shaped capillary glass burette 4, a titrant control device 3, and a silica gel cover.

[0026] The burette is provided with a U-shaped capillary glass burette 4, wherein the height of the tip of the capillary burette is higher than the scale line of the tube body.

[0027] The upper mouth of the burette is equipped with a silica gel cover.

[0028] The burette is provided with a titrant control device 3 .

[0029] The burette body is provided with a scale line 2, and the upper wide-diameter part is provided with a silicone tube 6 connected with a titrant control device.

[0030] A method for using a leak-proof drop-proof burette, based on the leak-proof drop-proof burette, in fact it controls the purpose of titration without leaking, specifically comprising the following steps:

[0031] Connect the titration solution control device 3 to the burette through the silicone tube 6, and add the ...

no. 2 example

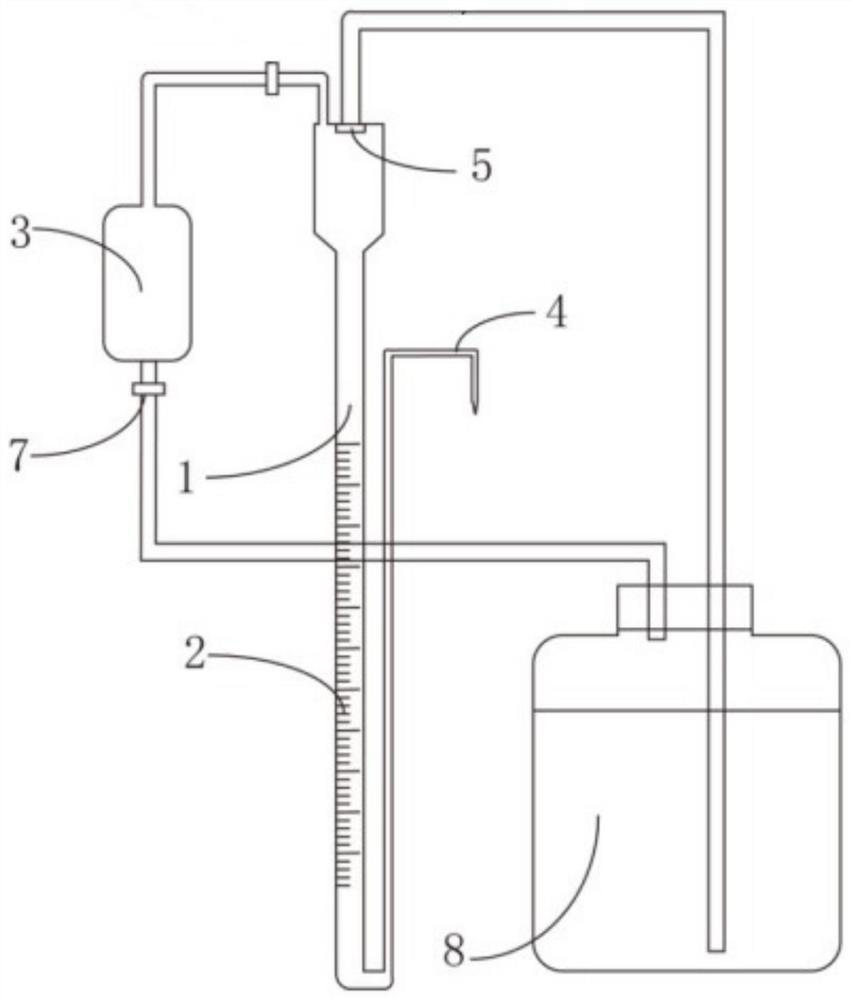

[0033] Such as figure 2 As shown, a drip-proof titration system includes a burette body 1 , a U-shaped capillary glass burette 4 , a titrant control device 3 , and a liquid storage bottle 8 .

[0034] A silicone tube 6 communicating with each other is provided between the burette body 1 , the titration solution control device 3 and the liquid storage bottle 8 .

[0035] A cut-off valve 7 is arranged on the silica gel pipeline.

[0036] The burette body is provided with a U-shaped capillary glass burette 4, and the burette body is provided with a scale line 2, wherein the height of the tip of the capillary burette 4 is higher than the scale line 2 of the tube body, and a one-way check valve is installed on the top of the burette.

[0037] A method for using an anti-leakage titration system, based on the anti-leakage titration system, to achieve the purpose of controlling titration without leakage, specifically comprising the following steps:

[0038] Connect the titrant cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com