Rigid hinged-lid packet

A packaging box and hinge technology, which is applied in the field of flip-top hard shell packaging boxes, can solve the problems of slow working speed, hard scratching of clothing fibers, and difficulty in aligning two circular profiles with each other, so as to avoid rapid wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

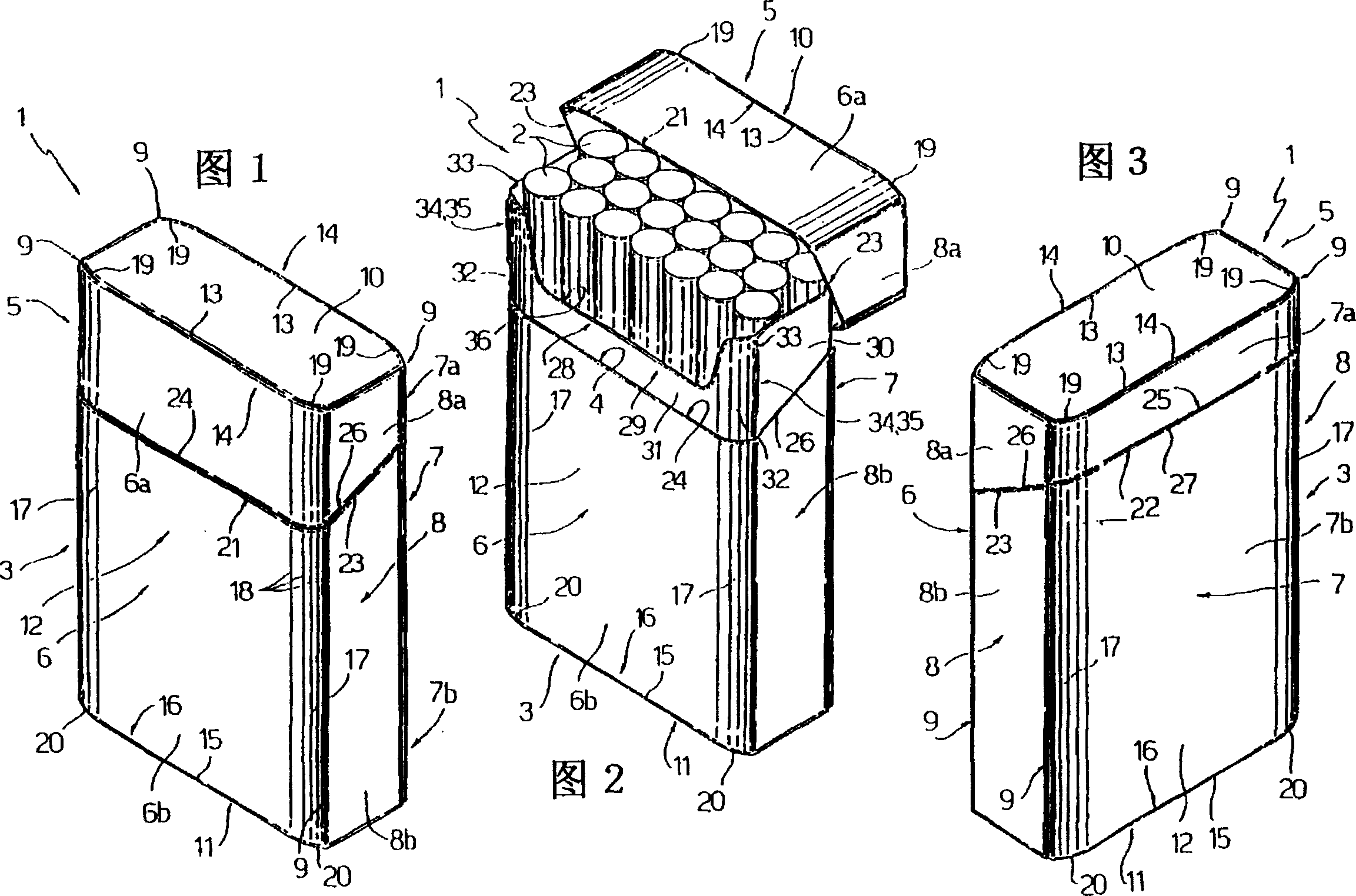

[0023] Numeral 1 in Fig. 1 to Fig. 5 indicates a whole cigarette case containing a group of cigarettes 2, wherein the cigarettes are arranged in layers. In the embodiment shown, the cigarettes are three-ply, wherein the middle ply has fewer cigarettes 2 than the outer two plies.

[0024] The cigarette case 1 comprises a cup-shaped lower bottom container 3, which is open at its upper end 4; Rotate between to open and close the upper end 4 respectively.

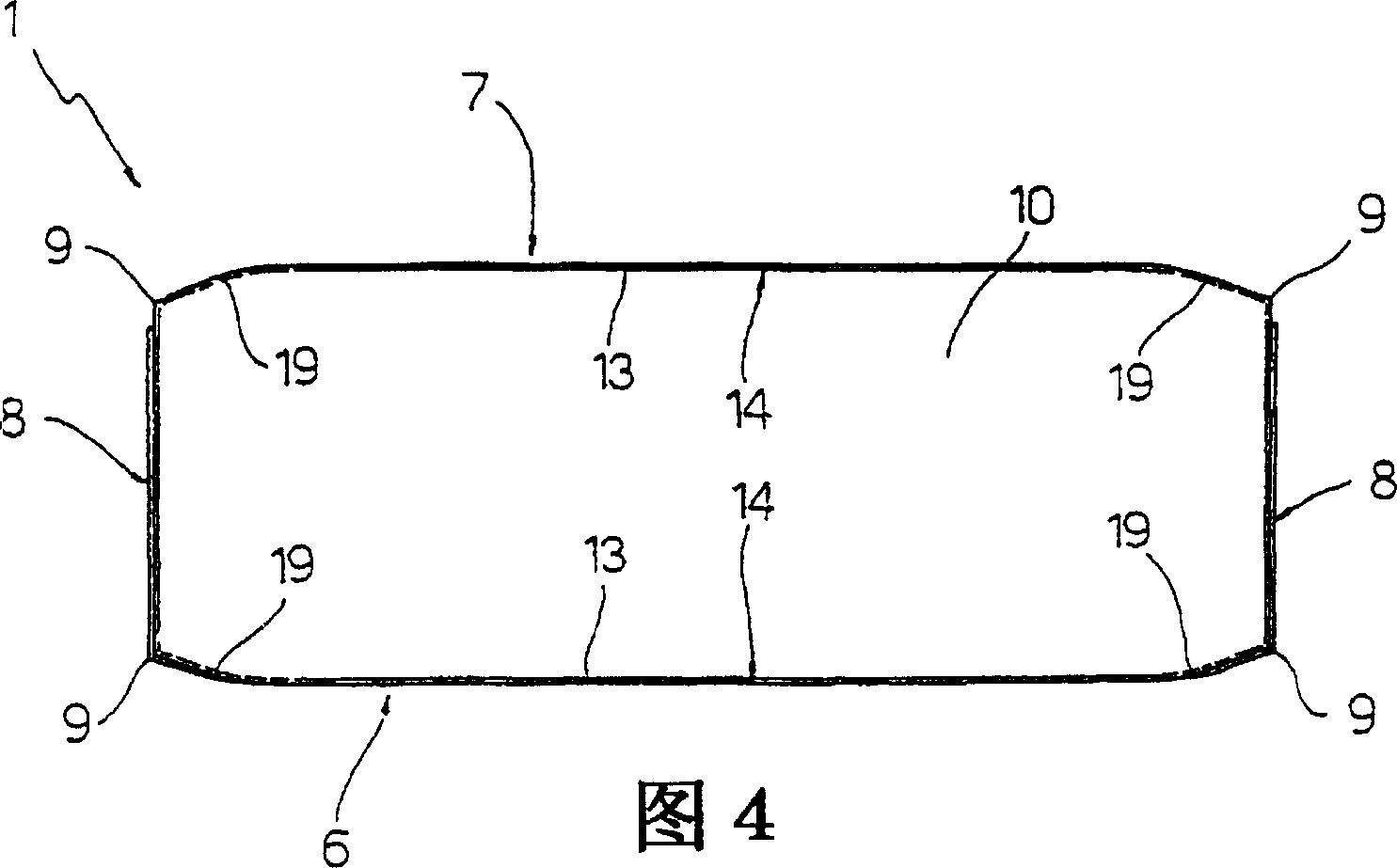

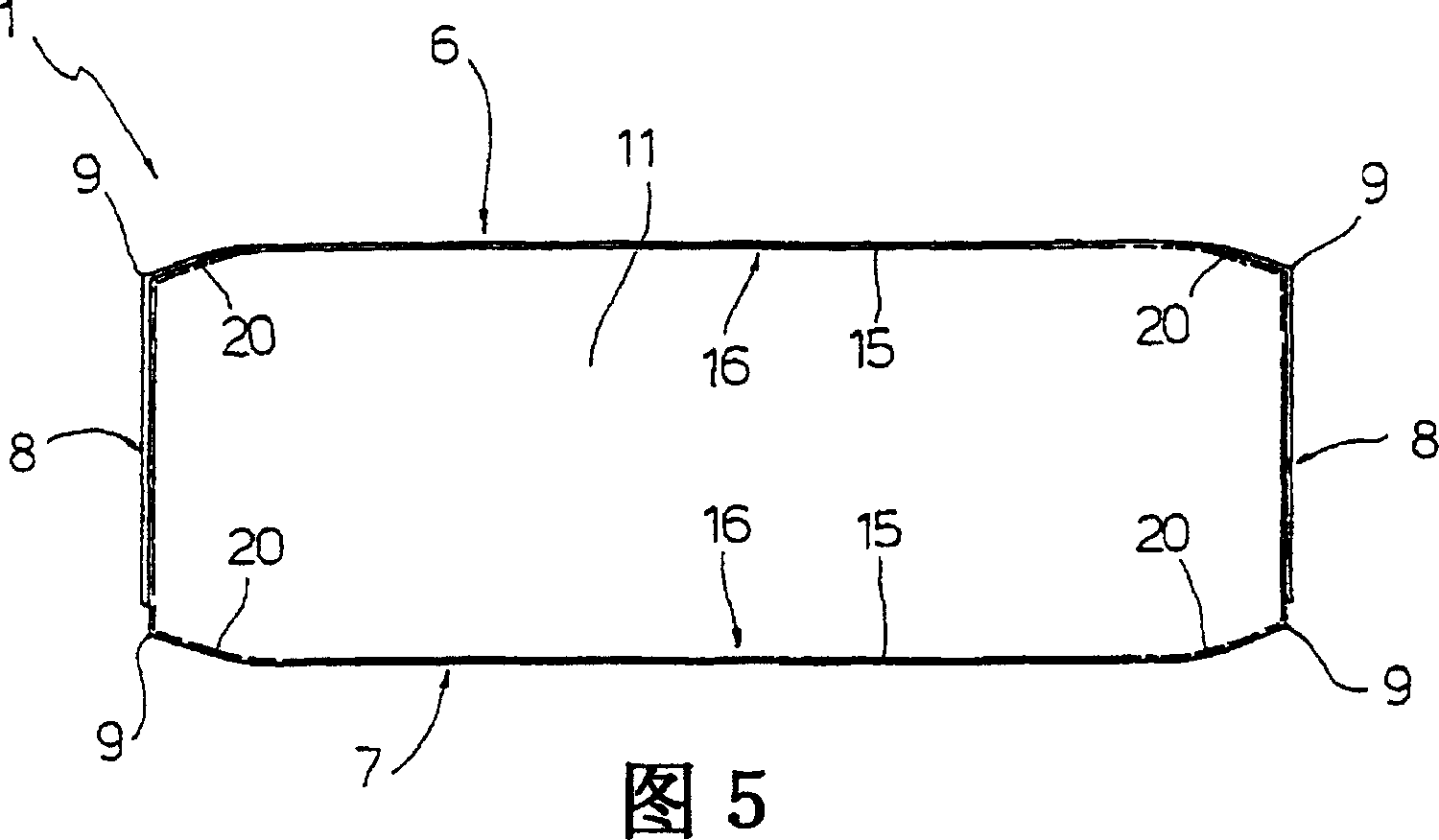

[0025] When the top cover 5 is closed, the cigarette case 1 is substantially a rectangular parallelepiped, which is surrounded by a front wall 6 and a rear wall 7, two sides 8, a top wall 10 and a bottom wall 11, wherein: The front wall 6 and the rear wall 7 are basically kept parallel to each other and bent outward; the two sides 8 are parallel to each other and are generally perpendicular to the side walls 6 and 7, and at the corresponding sharp edges 9 and the walls 6 and 7 connected together; the top wall 10 and a bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com