Reshaping station for blow molding machines without pressure pads

A molding station and blow molding technology, applied in the field of molding stations, can solve the problems of high cost, high cost, high expenditure, etc., and achieve the effect of avoiding rapid wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

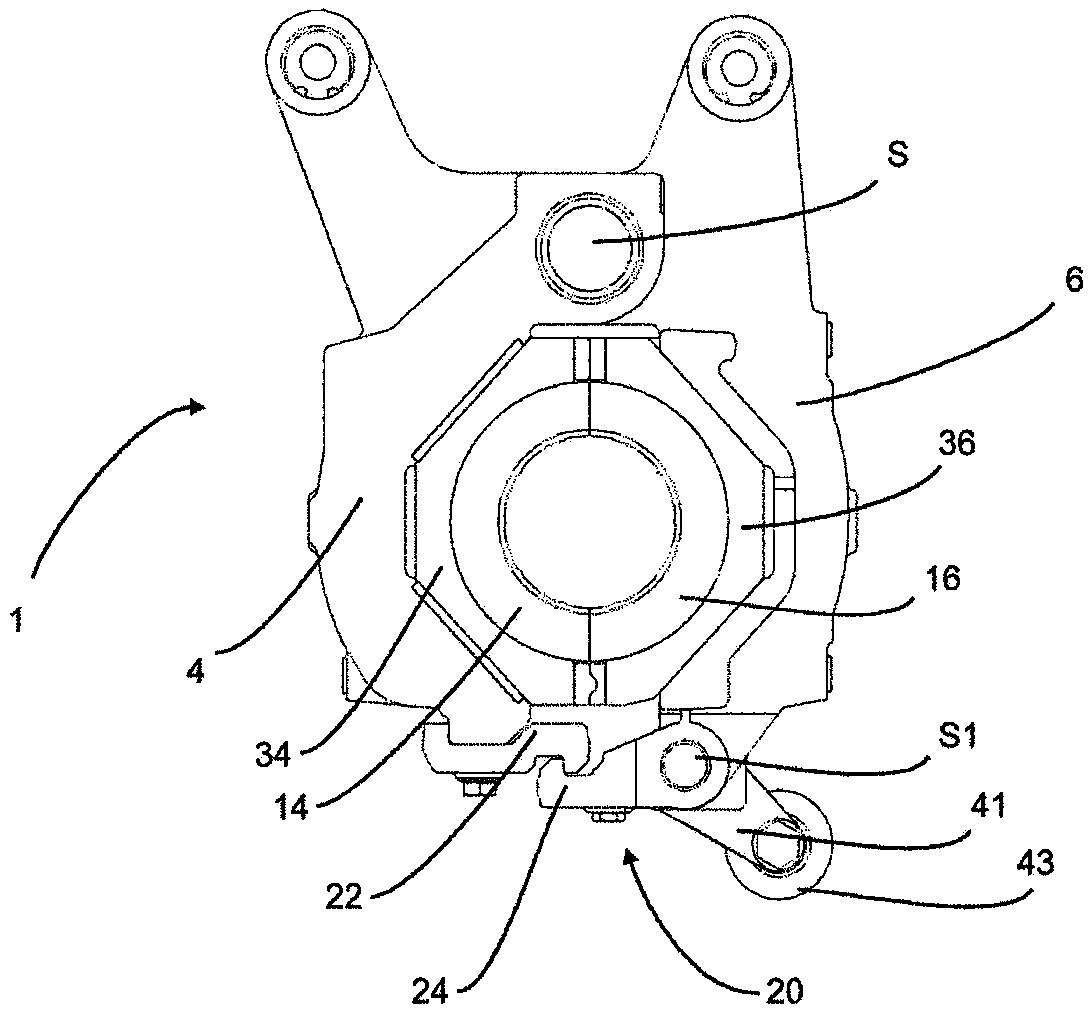

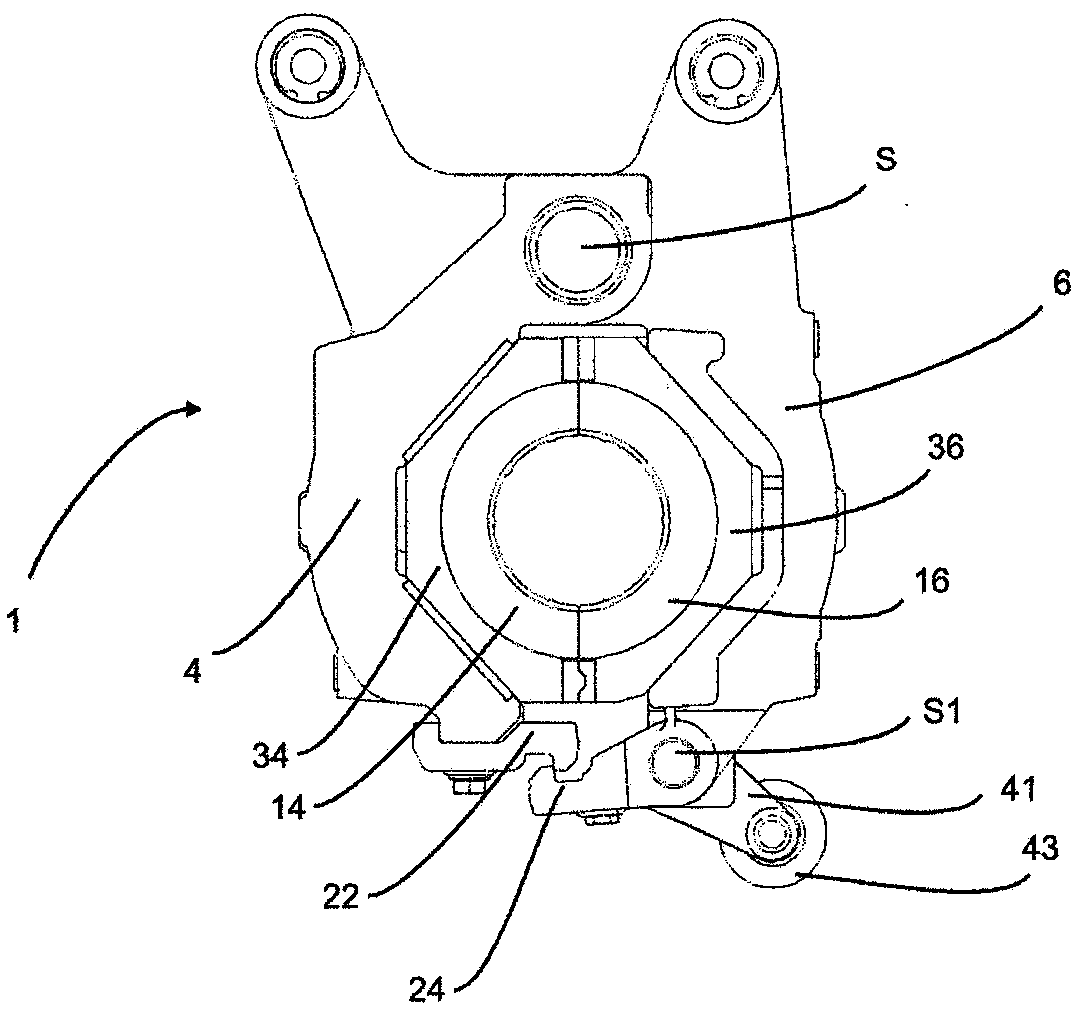

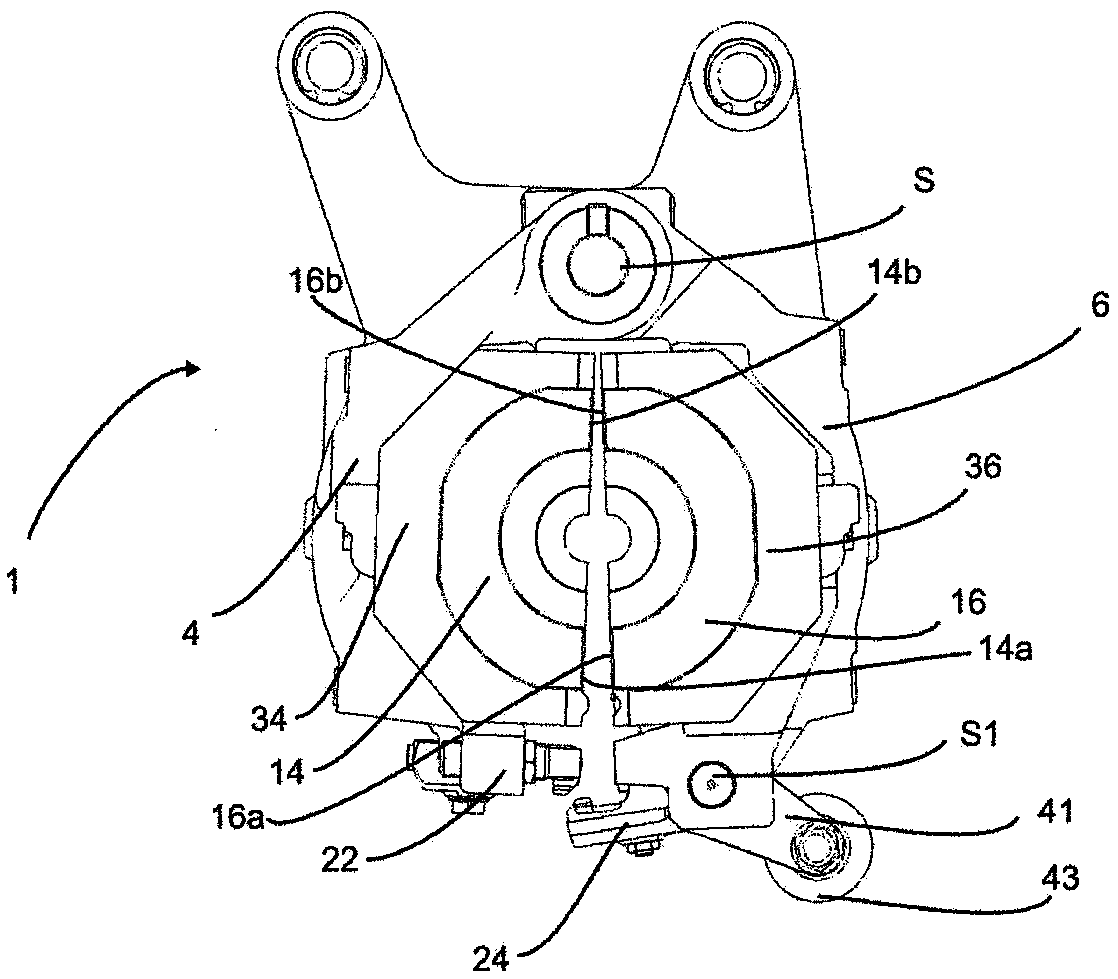

[0051] exist figure 1 A forming station 1 according to the invention is shown in . The forming station 1 has two side supports 4 and 6 . They are rotatable about the main axis S relative to each other. In this case, both side supports may rotate about this main axis. It is also possible that only one of the two side supports rotates about the main axis. It is also conceivable to provide two axes parallel to each other about which the two side supports rotate. Here, the main axis S or the corresponding rotational axis runs perpendicular to the drawing plane. The mold shells 34 and 36 are each arranged on two blow mold supports. The blow mold sides 14 and 16 are arranged successively on these mold shells 34 and 36 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com