Plug connector terminal assembly

A technology for plug-in connectors and terminal assemblies, applied in the direction of fixed/insulated contact members, etc., can solve the problems of low service life and large investment of plug-in connectors, and achieve the effect of improving sliding performance, reducing contact area and reducing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

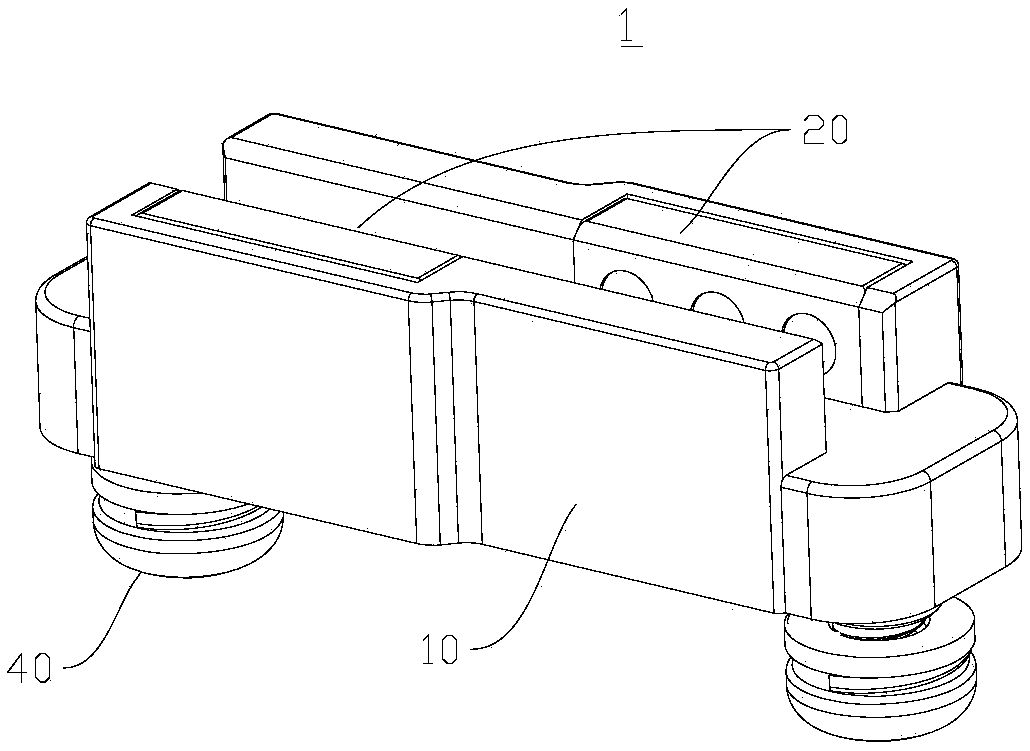

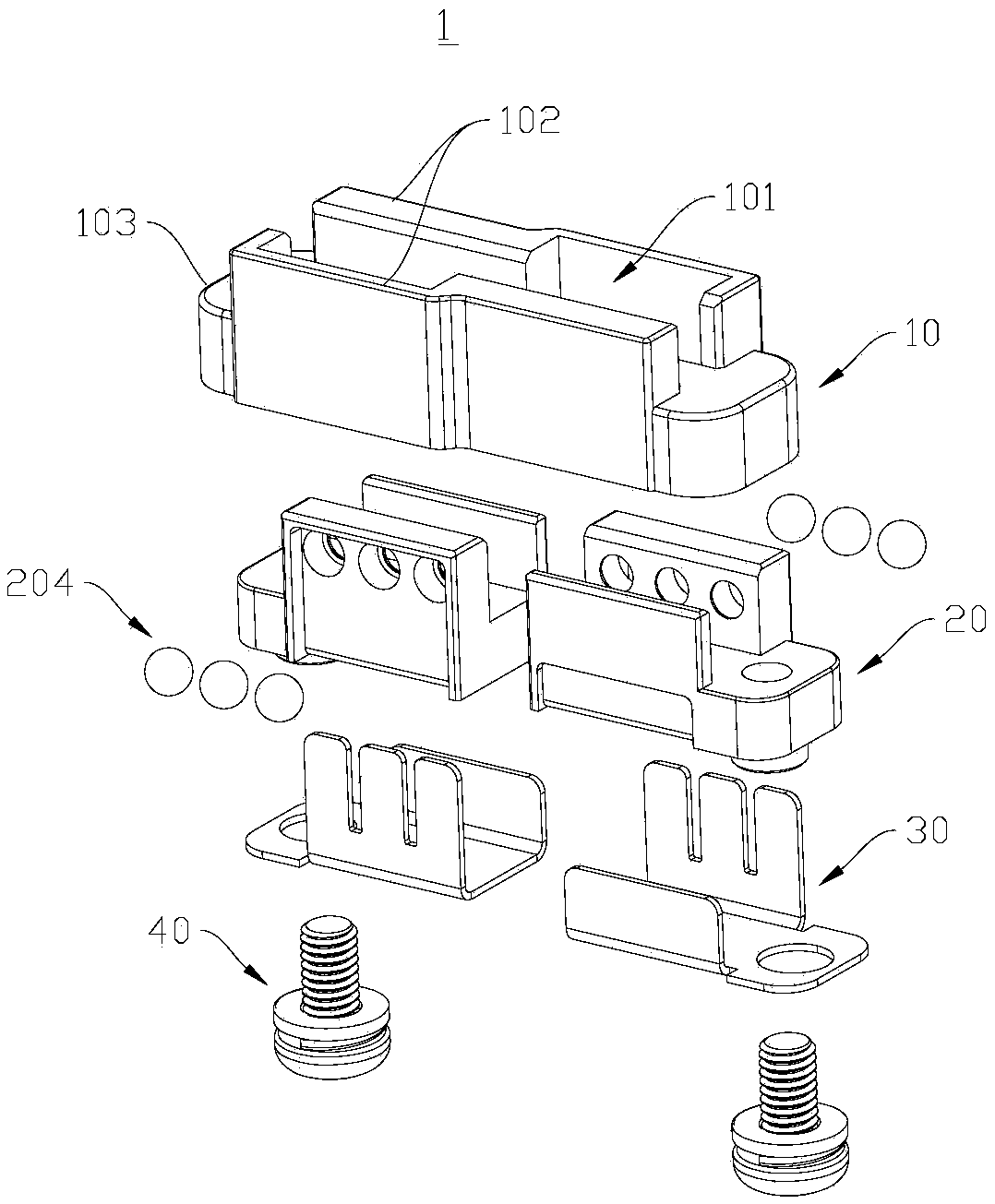

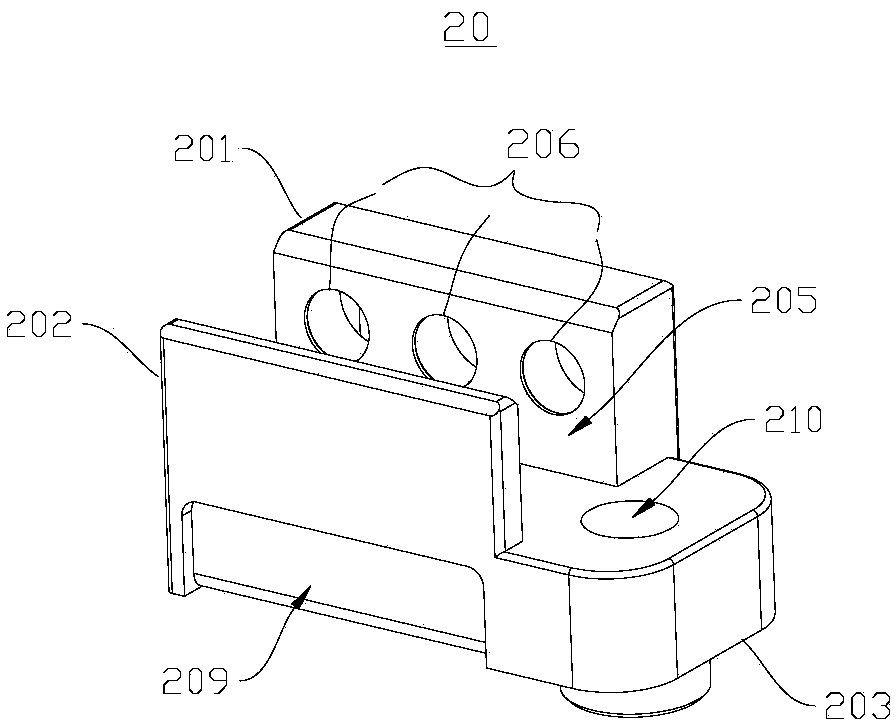

[0029] Please refer to figure 1 and figure 2 The plug connector terminal assembly 1 shown in the embodiment of the present invention includes: a body 10 , a fixing block 20 disposed on the body 10 , and conductive balls 204 and connecting terminals 30 respectively disposed on the fixing block 20 . The fixing block 20 , the connecting terminal 30 and the body 10 are fixedly connected by a screw set 40 . The screw set 40 includes screws, flat washers and spring washers.

[0030] Please refer to figure 2 , the body 10 is a block structure made of insulating material, preferably plastic material, which is light in weight and easy to process and shape. like figure 2 As shown, the shape of the body 10 matches the fixing block 20 , which has two vertical plates 102 arranged at intervals, and a horizontal plate 103 arranged at the bottom of the vertical plates 102 . An installation cavity 101 for accommodating the fixing block 20 is formed between the vertical plate 102 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com