Anti-freezing pneumatic pick

A technology of air picks and pick barrels, which is applied in the direction of picks, striking tools, light impact tools, etc. It can solve the problems that are difficult to apply, affect the high-pressure air source to quickly enter the pick barrel, and condense, so as to achieve the effect of good antifreeze function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

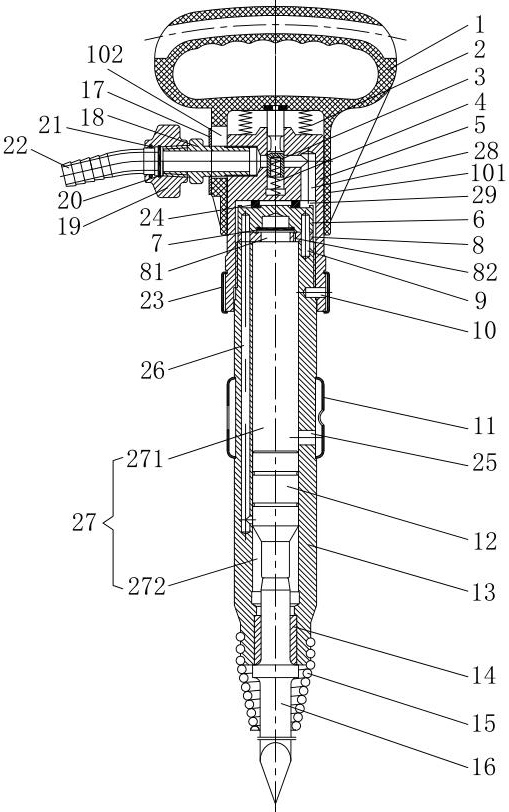

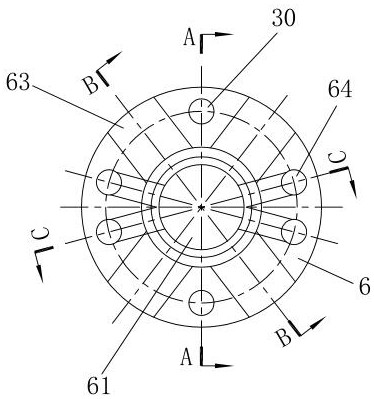

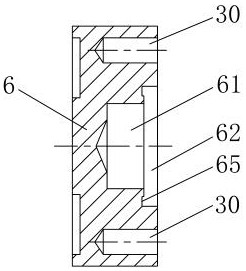

[0024] Such as Figure 1~Figure 7 As shown, 1. pick handle, 101. handle cover, 102. movable hole, 2. pick handle spring, 3. blocking valve, 4. blocking valve spring, 5. handle body, 6. valve cabinet, 61. valve cabinet hole , 62. Valve plate hole, 63. Ventilation groove, 64. Valve cabinet connection hole, 65. Ring groove, 7. Valve plate, 8. Valve pad, 81. Valve pad hole, 82. Return air hole, 83. Valve Pad connection hole, 9. Locating pin, 10. Stop pin, 11. Windshield, 12. Hammer body, 13. Pick barrel, 14. Brazing sleeve, 15. Head spring, 16. Pick brazing, 17. Washer, 18. Connecting pipe, 19. Nut, 20. Retaining ring for hole, 21. O-ring, 22. Air pipe, 23. Circlip, 24. Retaining ring, 25. Exhaust hole, 26. Air intake hole, 27. Working chamber, 271. Upper chamber, 272. Lower chamber, 28. Air intake channel, 29. Air intake chamber, 30. Pin hole.

[0025]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com