Automatic elastic-hook feeding device of spraying assembly line

A technology of elastic hooks and automatic feeding, which is applied in the direction of transportation and packaging, mechanical conveyors, conveyor objects, etc., and can solve the problems of multi-manpower, cost, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

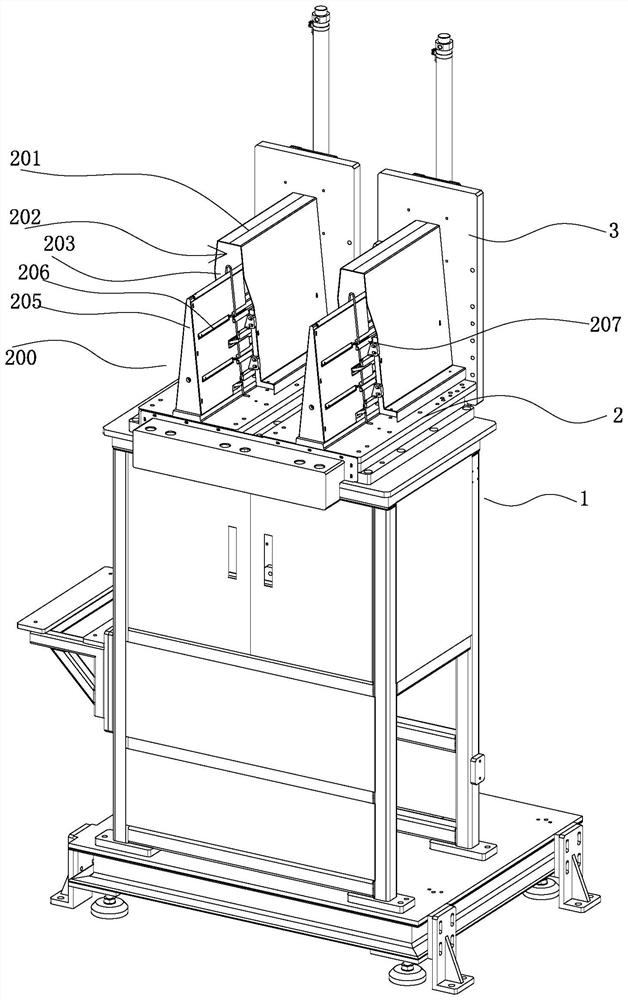

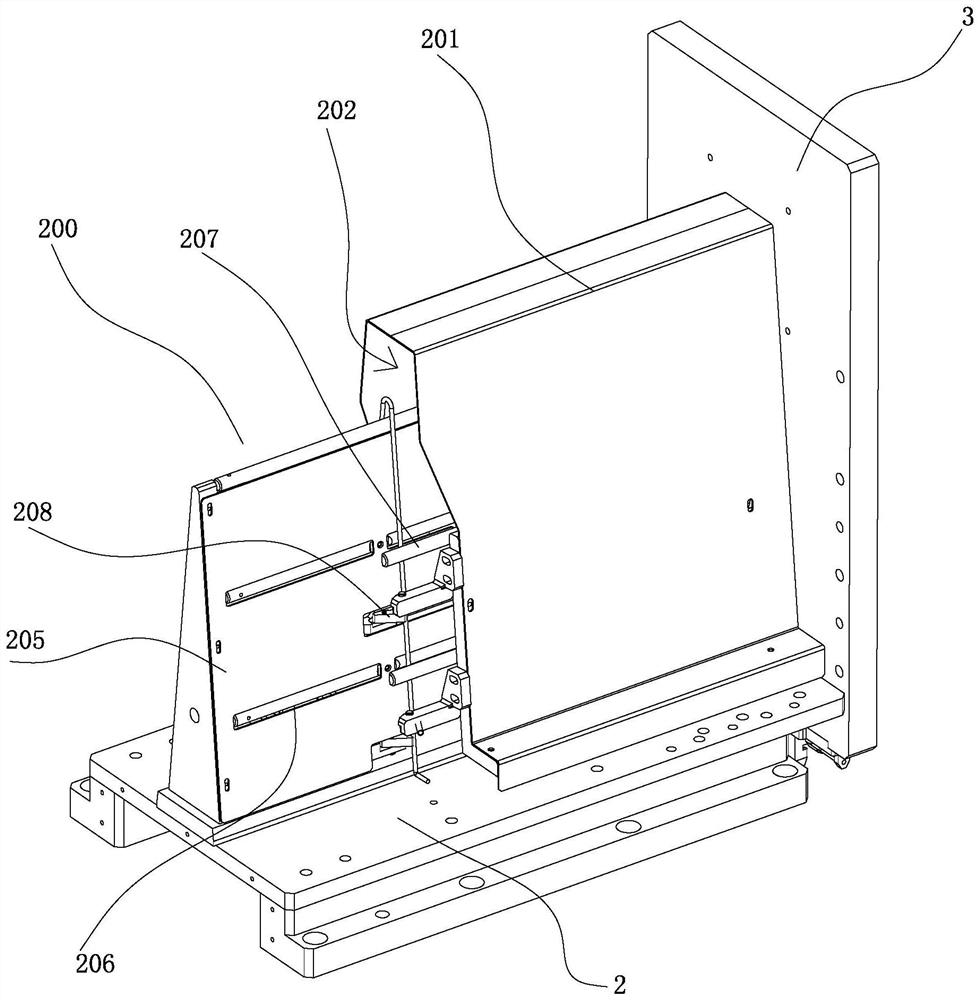

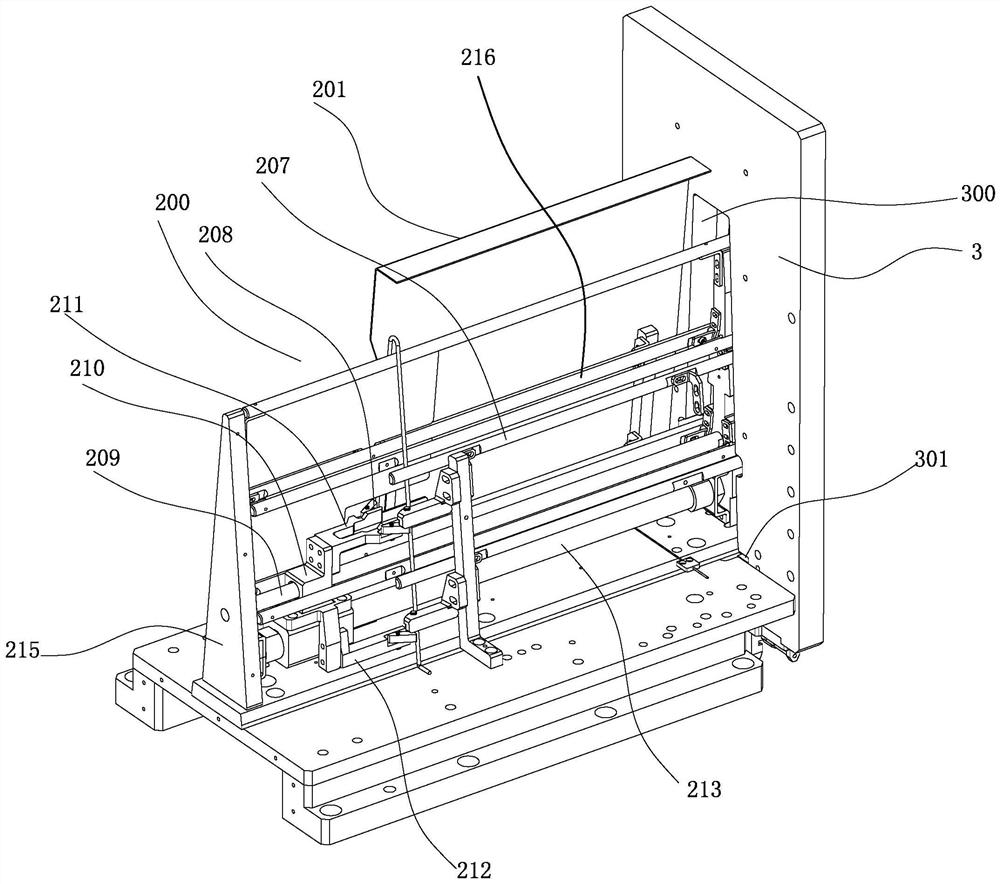

[0026] see figure 1 As shown, a kind of elastic hook automatic feeding device of the spraying assembly line of the present invention, it is installed on the frame 1 of spraying assembly line, is used for automatically conveying the elastic hook 4 that can be hooked on the piece to be sprayed, and its structure includes being installed on Base plate 2 on the frame 1, base plate 2 is connected with guide bracket 200 and shell 201, and shell 201 covers the outside of guide bracket 200, and the shape of guide bracket 200 matches with the shape of elastic hook 4; The shape of elastic hook 4 is V-shaped, and two free ends have two clips that can be hung on the piece to be sprayed; The way of card placement is stuck on the guide bracket 200; a delivery channel 202 for the elastic hooks 4 to be placed side by side is formed between the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com