Prefabricated part gantry hoisting device and using method

A technology of gantry hoisting and prefabricated components, applied in safety devices, walking mechanisms, transportation and packaging, etc., can solve the problems of unadjustable height of gantry, derailment, etc., and achieve the effect of avoiding derailment, ensuring safety and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

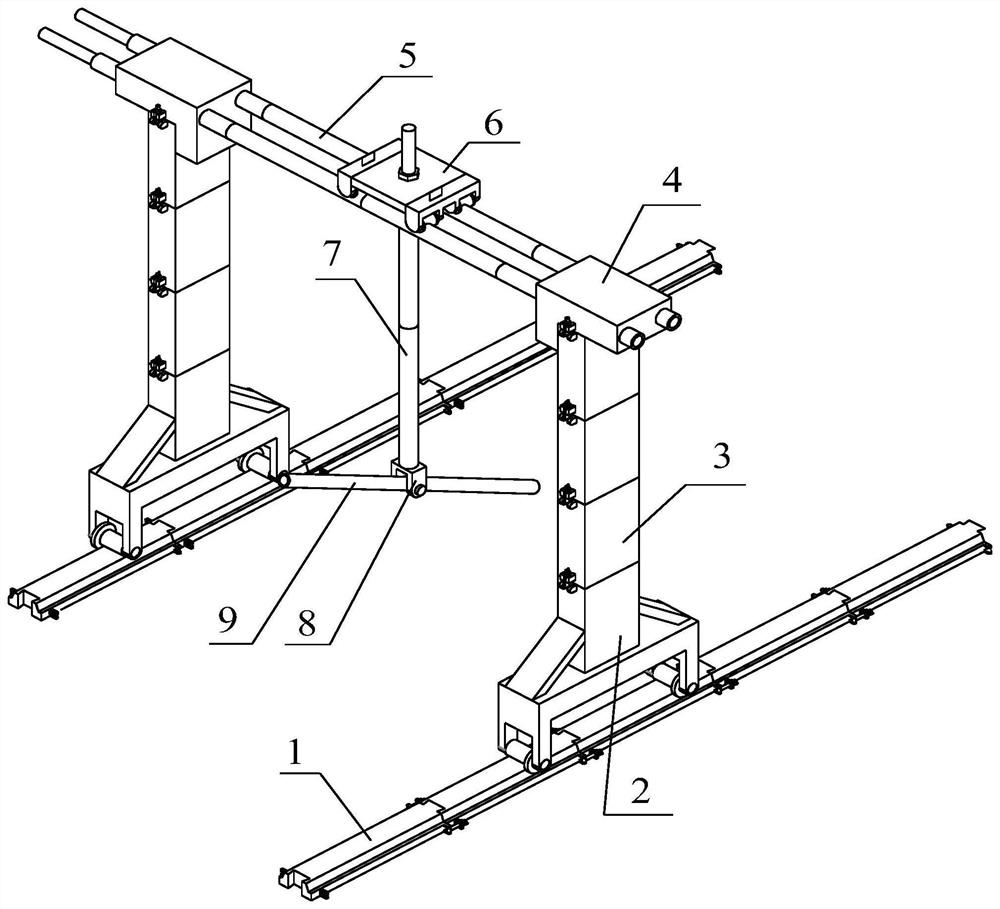

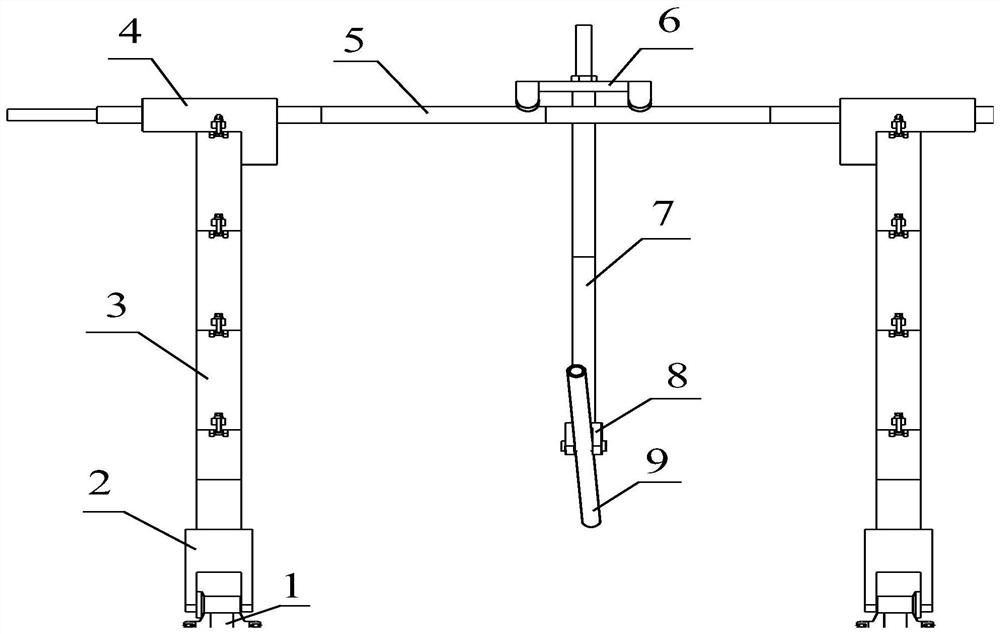

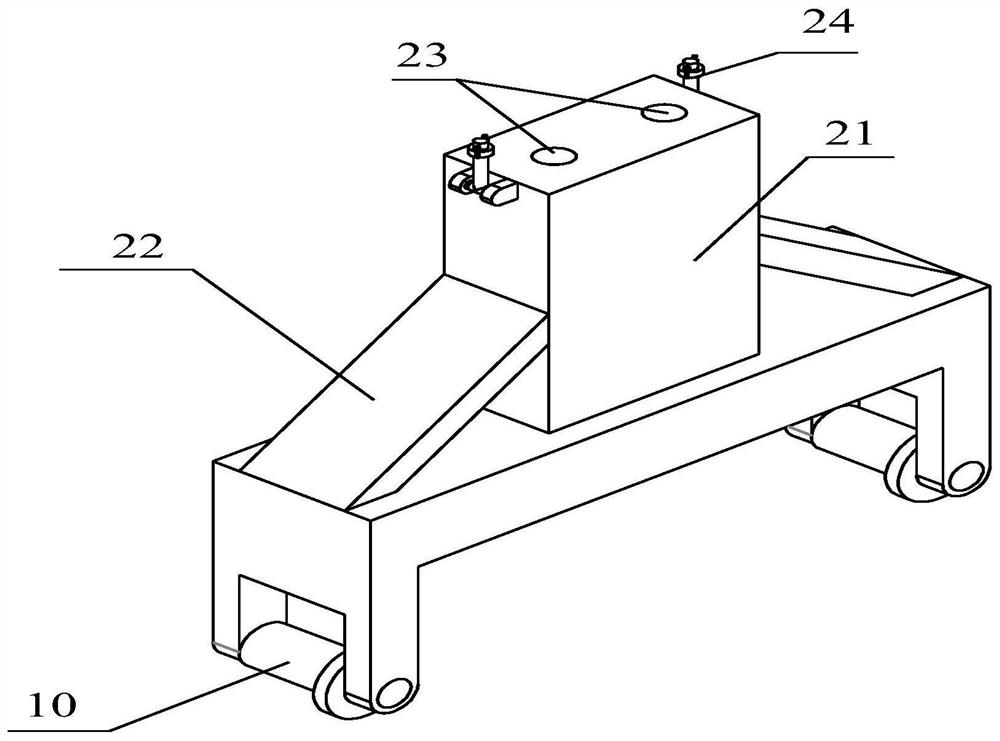

[0033] see figure 1 as well as figure 2 , the present invention provides a prefabricated component gantry hoisting device, the prefabricated component gantry hoisting device includes a track 1, a supporting column, a connecting beam 5, a boom 9, a top anti-derailment device 6 and a bottom anti-derailment device 10; the track 1 is two root, two rails 1 are arranged in parallel; the support column includes a left support column and a right support column opposite to the left support column; the structure of the left support column and the right support column is exactly the same; the bottom of the left support column and The bottom of the right support column is respectively arranged on the track 1 through the bottom anti-derailment device 10; the top of the left support column and the top of the right support column are connected by the connecting beam 5; the left support column, the connecting beam 5 and the right side The supporting columns together form a gantry; the gantr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com