Dynamic pushing type eccentric weight correction vertical drilling tool

A vertical drilling and dynamic technology, which is applied in directional drilling, engine components, engine sealing, etc., can solve the problems of insufficient weight limit of eccentric block, non-adjustable plunger pressure, limited thrust of wing plate, etc., to achieve the benefit of sand carrying and wellbore purification, high deflection correction capability, and large mediation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

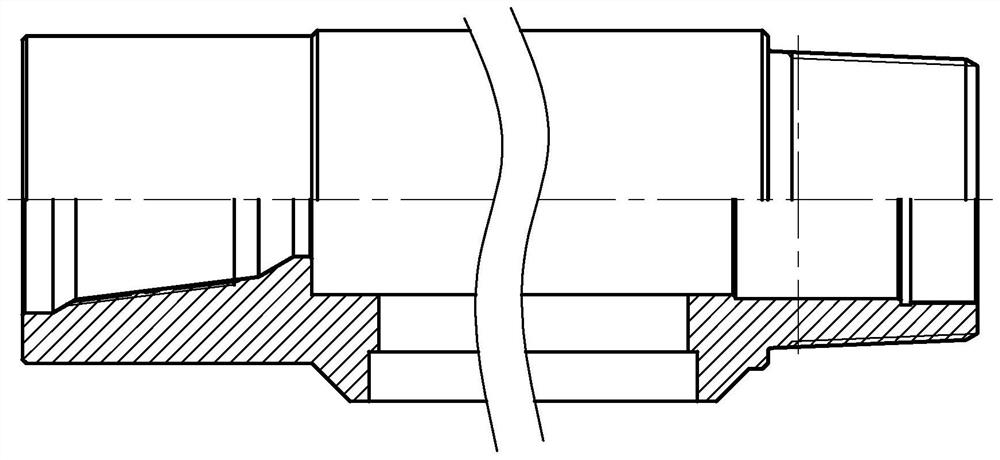

[0094] Borehole Mechanical Automatic Vertical Drilling Tool Design

[0095] Such as Figure 23-24 Shown, the structure of track cylinder 14 is as follows:

[0096] Material: hard alloy; three drilling fluid channels 14.1 are evenly distributed in the circumferential direction of the orbital cylinder 14, and there are grooves for installing sealing rings on the upper and lower ends of the orbital cylinder 14, and one sealing ring is installed in each groove, a total of 2 .

[0097] Such as Figures 17-19 Shown, the structure of semicircular pipe 11 is as follows:

[0098] From left to right, they are sealing section, liquid supply section, sealing section and guide section. Material: hard alloy; the contact surface between the semi-circular tube 11 and the orbital cylinder 14 is matched with grinding, sealed and pressure-bearing; the liquid supply section is in the shape of a semi-circular arc concave inward along the circumferential direction, and the concave side is cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com