Mobile power detection system

A power detection and mobile technology, which is applied to the components of electrical measuring instruments, measuring devices, continuity testing, etc., can solve the problems of frequently moving lifting equipment, small detection range, and time-wasting, so as to save manpower and facilitate operation , the effect of increasing the detection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

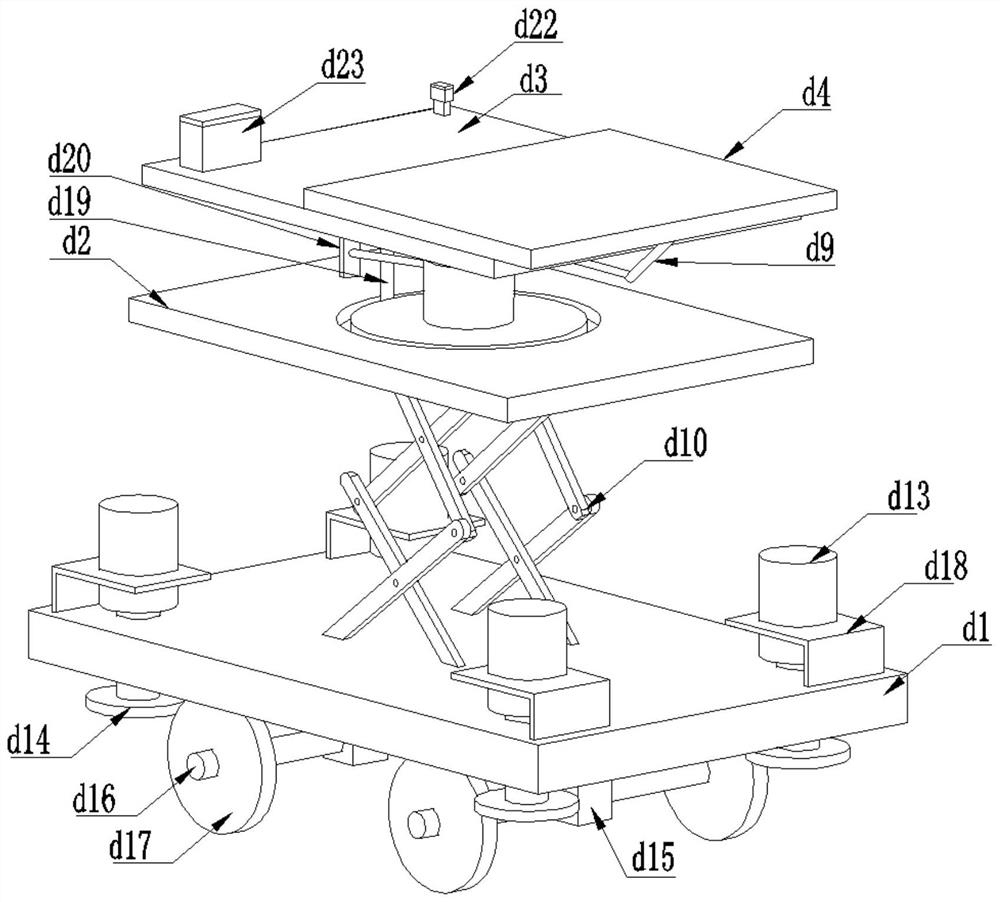

[0032] Embodiments of the present invention provide a mobile power detection system, such as figure 1 As shown, it mainly includes a lifting device and two tool boxes respectively placed on the top of the lifting device. The breakpoint detector d23 and the wiring clamp d22 are respectively placed in the two tool boxes. The lifting device is used to lift the inspector To a predetermined height, the breakpoint detector d23 is used to detect whether there is a breakpoint on the line, and the wiring clamp d22 is used to assist the inspector to reconnect the disconnected line. Specifically, except that the wiring clamp d22, the breakpoint detector d23 and the lifting device in this embodiment can be directly replaced by related equipment and tools in the prior art, this embodiment especially recommends the following structures for fabrication:

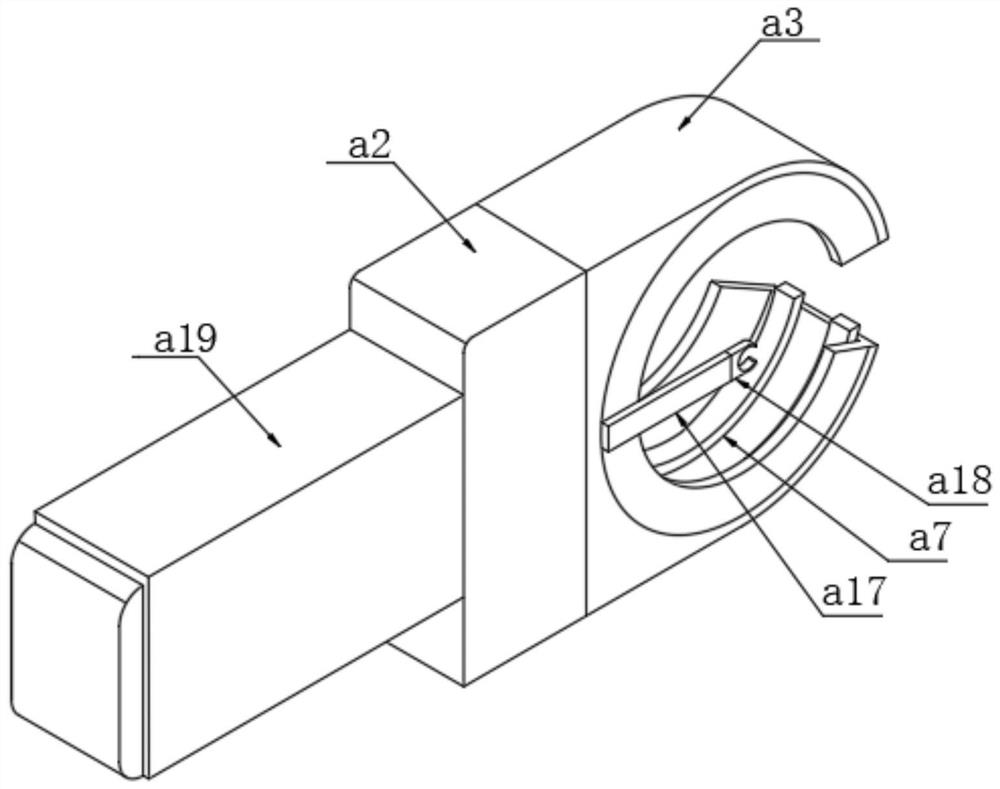

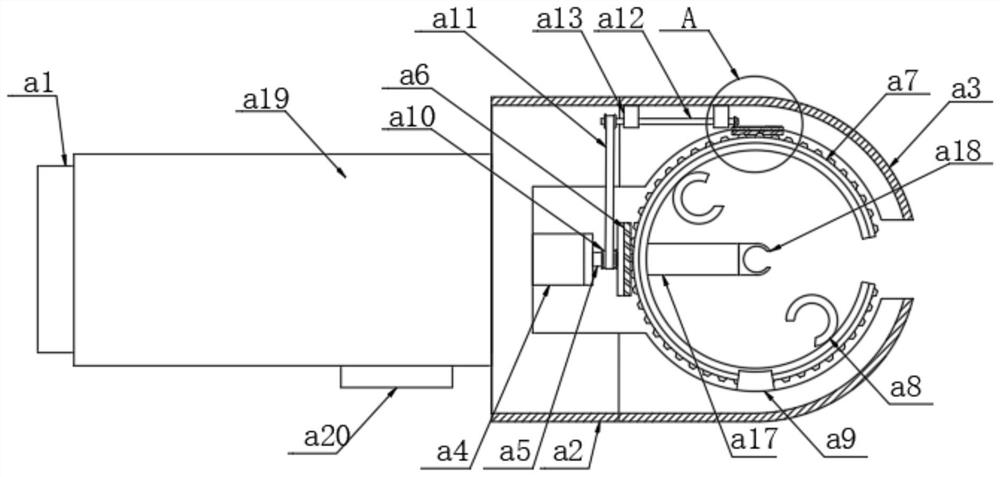

[0033] see figure 2 , image 3 and Figure 5 , the above-mentioned wiring pliers d22 includes a handle a1, and a wiring assembly is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com