Multiple pulsed-welding method

A technology of pulse welding and welding method, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., and can solve problems such as droplet shedding at the arc and poor welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

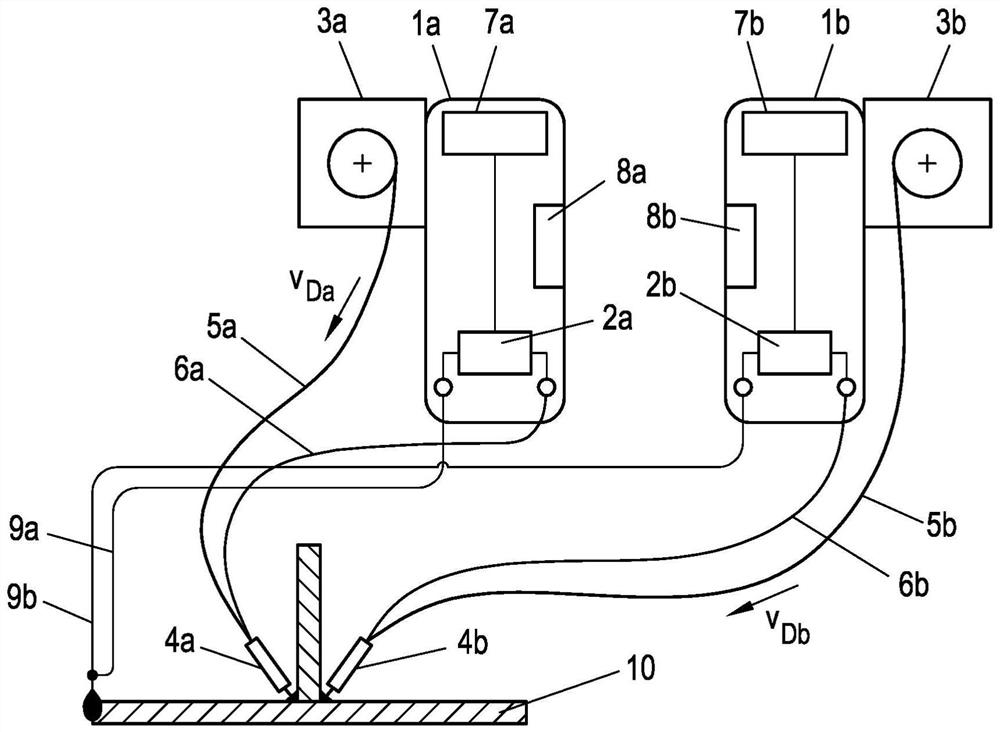

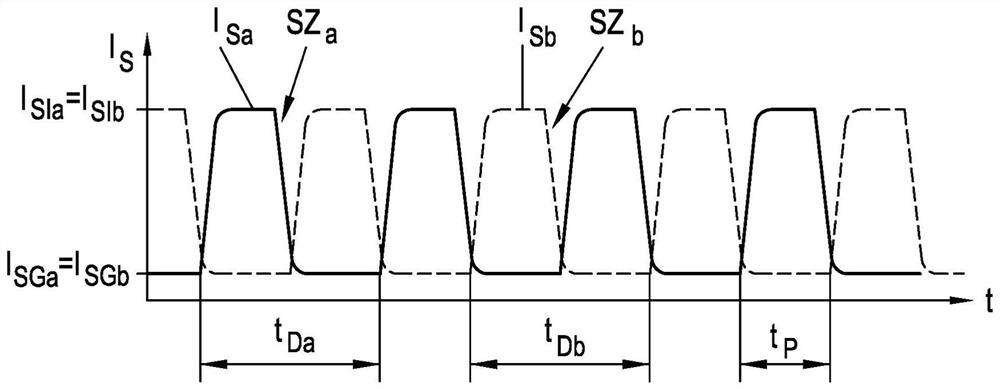

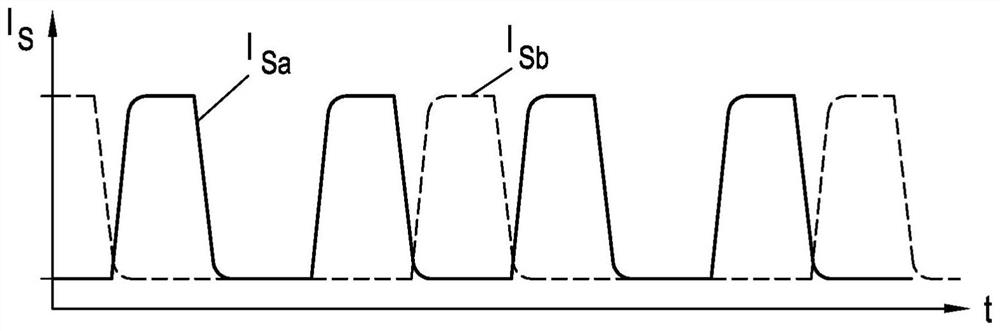

[0018] The invention will be elucidated below for a double-pulse welding method (ie, with two pulse welding processes) as an example of a multi-pulse welding method. However, it is of course conceivable to extend the embodiments below to multi-pulse welding processes with more than two pulse welding processes. The multi-pulse welding method is characterized in particular by the simultaneous operation of at least two pulse welding processes, thus two pulse welding processes in the case of a double-pulse welding process. Multiple pulse welding processes can all work in the same molten pool, but different pulse welding processes can also work in partially different molten pools.

[0019] exist figure 1 A possible configuration for a two-pulse welding process is schematically shown in , as an example of a multi-pulse welding process with two pulse welding processes that is frequently encountered in practice. Two separate welding devices 1a, 1b are provided, each having a power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com