Method for supplying current of switching valve of fuel injector

A technology of fuel injectors and switching valves, which is applied in the direction of fuel injection devices, fuel injection control, special fuel injection devices, etc., and can solve the problems of pre-injection disappearance and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

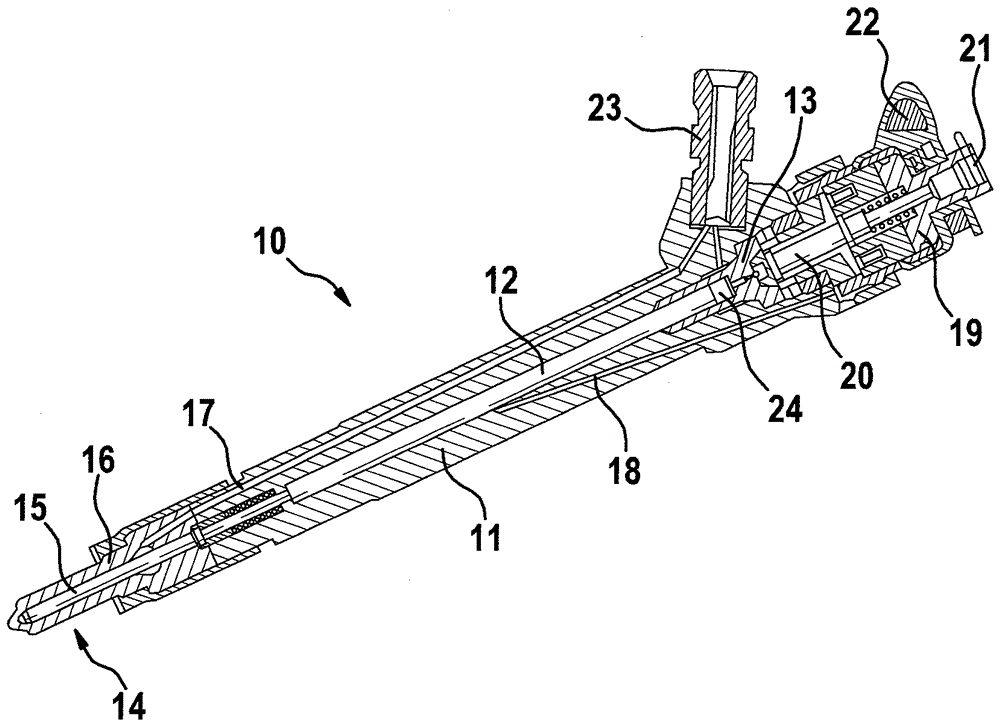

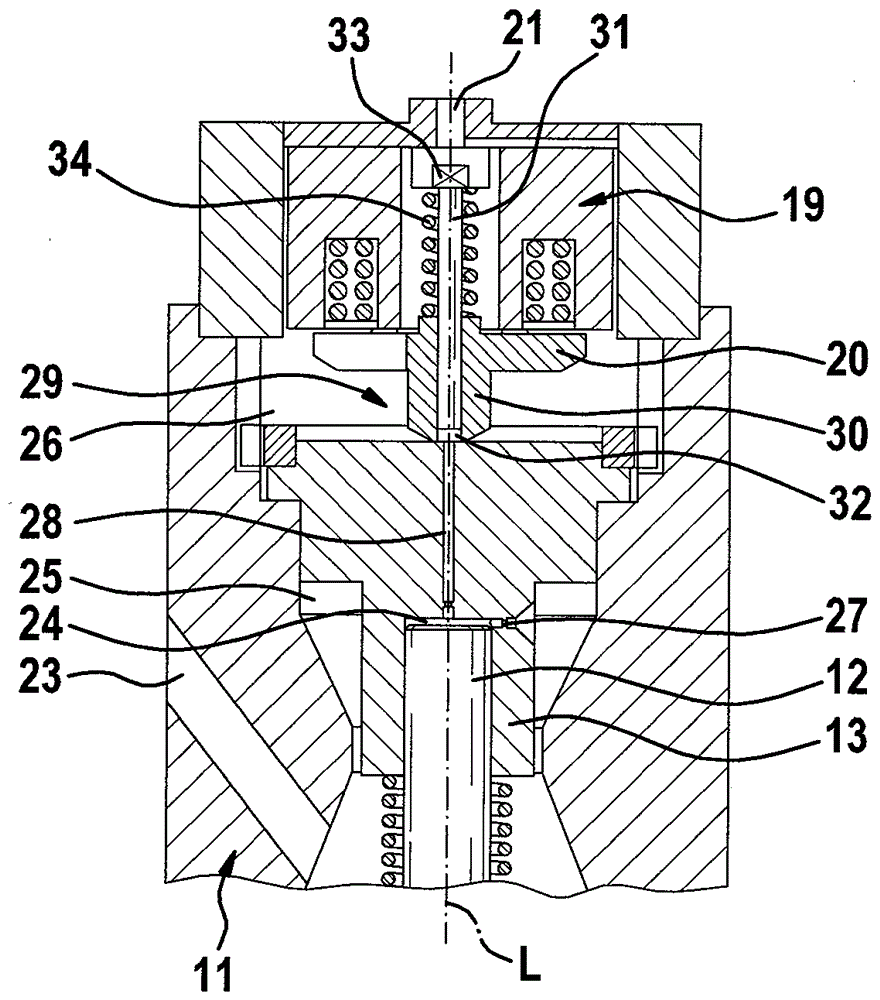

[0023] By means of the pair known in DE 10 2009 029 549 A1 and in figure 1 The adjustment of the fuel injector 10 shown in FIG. 1 illustrates one embodiment of the present invention. The fuel injector 10 comprises an injector body 11 in which a valve piston 12 is arranged. This valve piston is guided at the upper end within the valve part 13 . Its lower end extends in the direction of the nozzle 14 . The valve piston 12 is connected to a valve needle 15 of a needle valve 16 which is arranged inside the nozzle 14 . Furthermore, the valve piston 12 is connected to a high-pressure bore 17 and to a return bore 18 . Arranged at the upper end of the fuel injector 10 is a magnetic head 19 connected to the switching valve, an armature assembly 20 and a circuit 21 . Fuel injector 10 is also connected via an electrical connection 22 to an electrical energy source (not shown) and via a high-pressure connection 23 including a high-pressure slot filter to a fuel supply line (not shown)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com