Plate-shaped workpiece tool fixing clamp with original point positioning function and positioning method of plate tool fixing clamp

A technology of tooling fixation and origin positioning, which is applied in the field of plate-shaped workpiece processing, can solve problems such as error accumulation, plate origin positioning, and reduce processing accuracy, and achieve the effects of convenient fixation, improved precision, and convenient origin positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

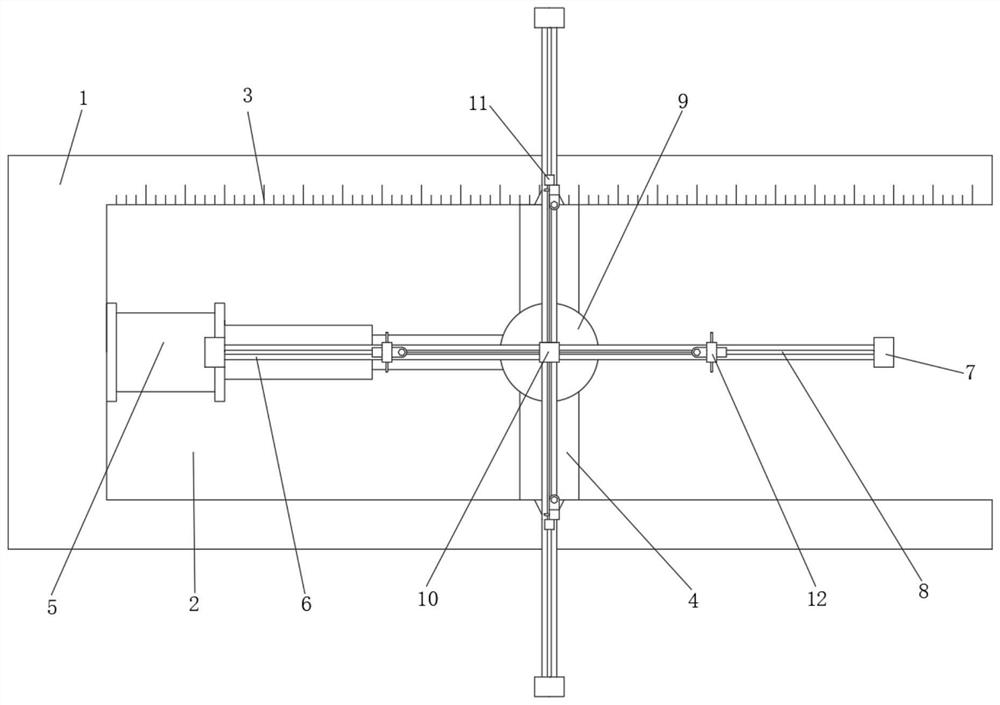

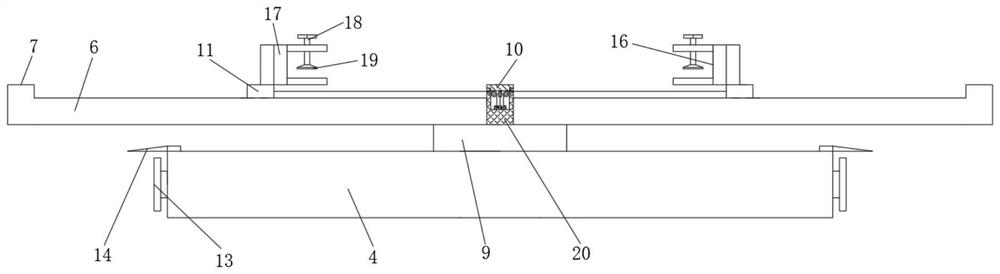

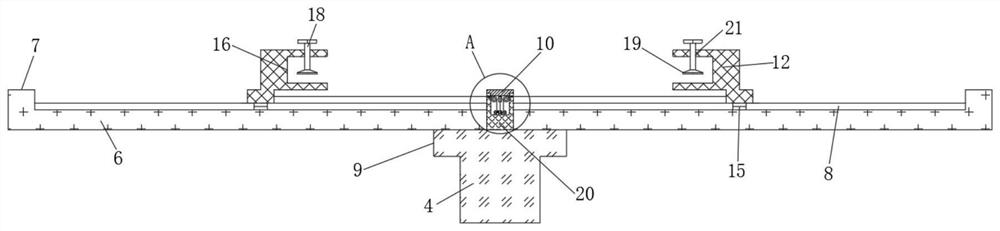

[0041] Embodiment 1: Rectangular plate positioning;

[0042] The origin of the rectangular plate is usually set at the corner or the center. In order to achieve convenient positioning, the corners perpendicular to each other are selected for positioning. First, through the cooperation of the chute 8 and the second slider 15, the horizontal clamping block 12 is realized. Sliding installation with the longitudinal clamping block 11, adjust the left lateral clamping block 12 and the longitudinal clamping block 11 at the front end to move in the direction of the pressure end cover 10, when the left lateral clamping block 12 and the longitudinal clamping block at the front end When the outer wall of the block 11 is attached to the chassis 9, the stepped block on the horizontal clamping block 12 and the extension plate 17 on the longitudinal clamping block 11 are vertically attached to each other. point overlap;

[0043] Then the motor 27 drives the winding roller 26 to rotate, so ...

Embodiment 2

[0045] Embodiment 2: circular plate positioning;

[0046] The origin of the circular plate is usually set at the center of the center, and the horizontal clamping block 12 and the longitudinal clamping block 11 are pulled at equal lengths away from the pressure-bearing end cover 10. The length of the pull is greater than the length of the workpiece to be positioned and clamped, and then the circular The workpiece is placed on the upper end of the pressure-bearing end cover 10, and the motor 27 is controlled to rotate at a constant speed, so that the pull rope 23 is stored at a constant speed, and then the clamping of the horizontal clamping block 12 and the longitudinal clamping block 11 to the circular arc outer wall of the circular workpiece is realized. Four groups of transverse clamping blocks 12 and longitudinal clamping blocks 11 are simultaneously pressed against the outer wall of the circular plate, and the center of the circular plate coincides with the center of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com