Patents

Literature

38results about How to "Achieve squeeze fixation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

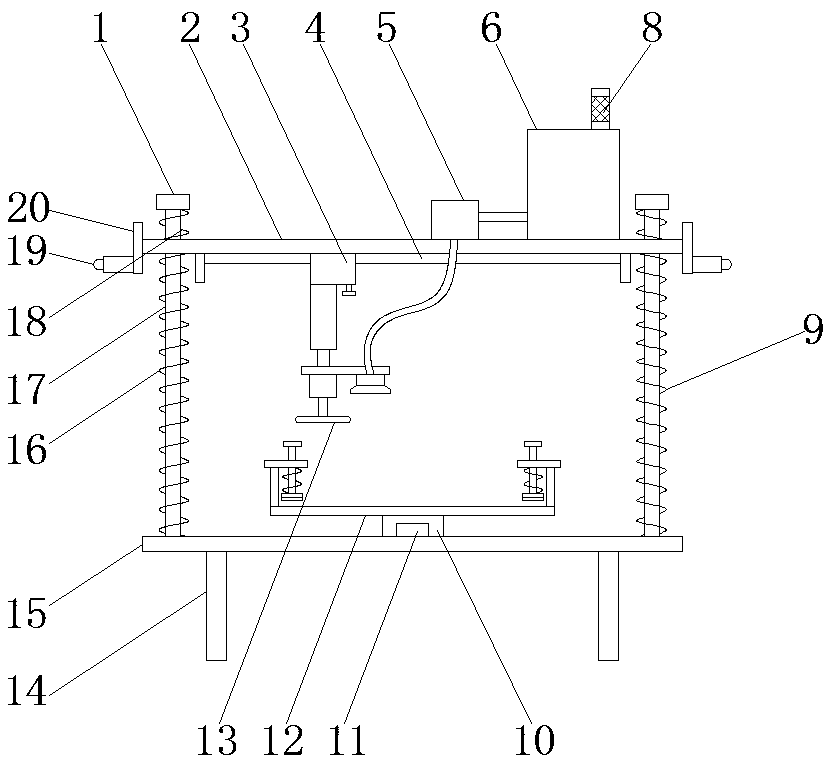

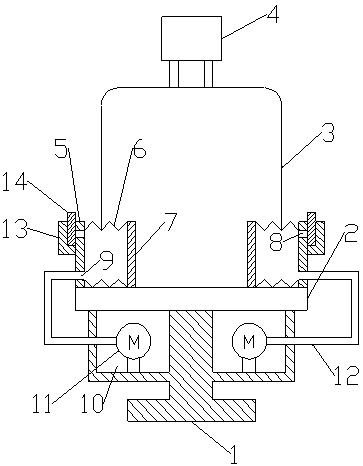

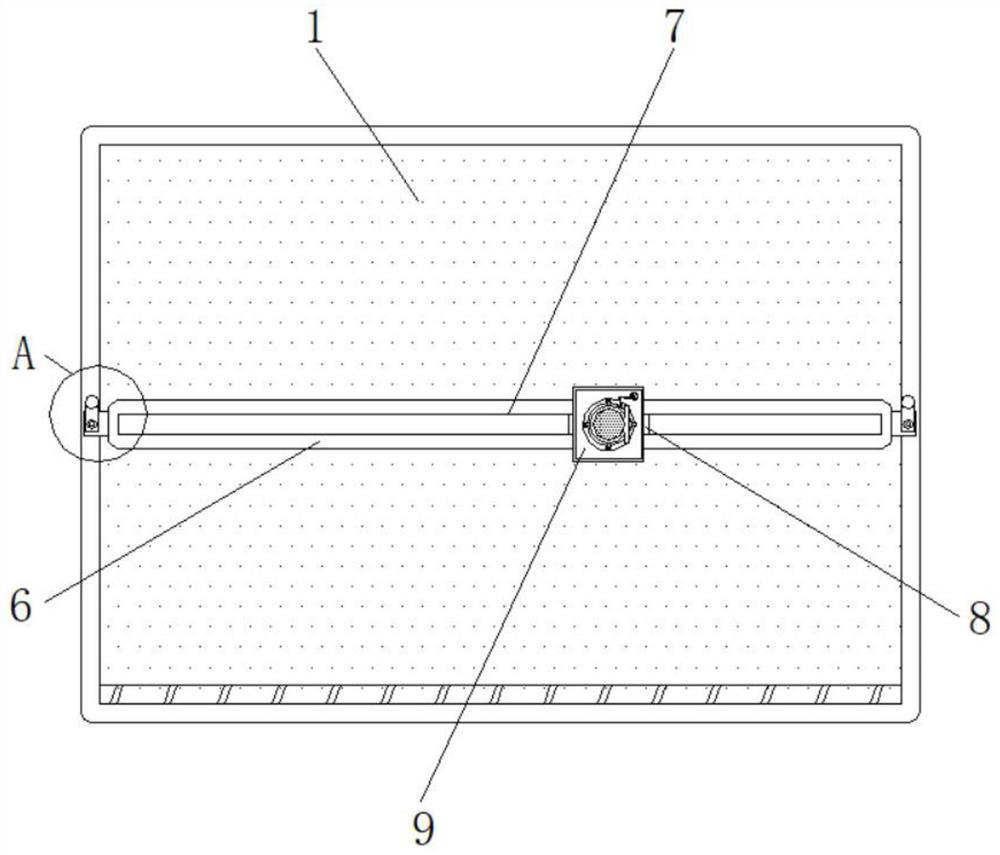

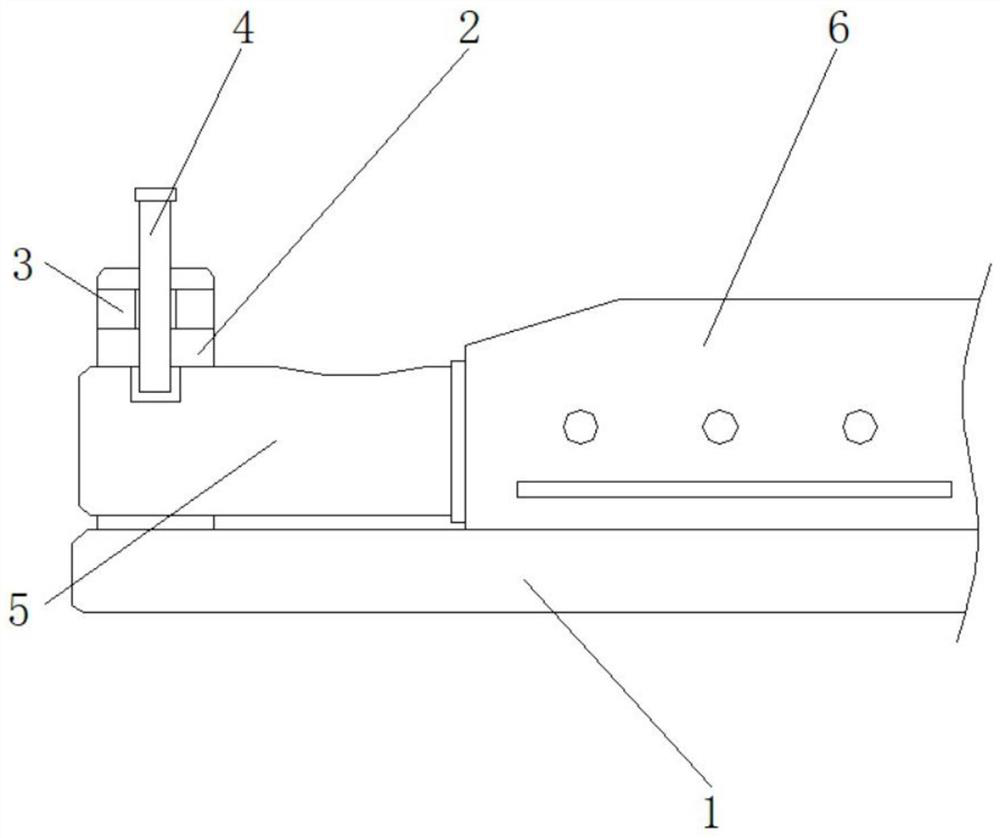

Board grinding device for circuit board processing

PendingCN108942457AIncrease frictionEasy to fixGrinding carriagesGrinding drivesEngineeringFriction force

The invention discloses a board grinding device for circuit board processing. The board grinding device for the circuit board processing comprises non-slip mats, a bottom board, a top board, an exhaust fan, a collecting box, a first sliding block and a second sliding block; the friction force between the bottom of a pressing board and a substrate is increased by arranging the non-slip mats, so that the effect of fixing the position of the substrate is improved; the movement of the position of the substrate in a process of grinding the substrate is avoided; in a descending process of the top board, a first returning spring and a third returning spring are separately extruded and stretched to push the first sliding block and the second sliding block to slide on a first sliding rail and a second sliding rail respectively, so that the purpose of grinding different positions on the substrate is achieved; the practicability of equipment is improved; air is exhausted by utilizing the exhaustfan, so that dust produced in a substrate grinding process further enters the collecting box through an air guide pipe after entering a dust sucking cover; and therefore, the dust in the substrate grinding process is collected, and the pollution to environment because the dust flies around is avoided.

Owner:湖北荣宝电子科技有限公司

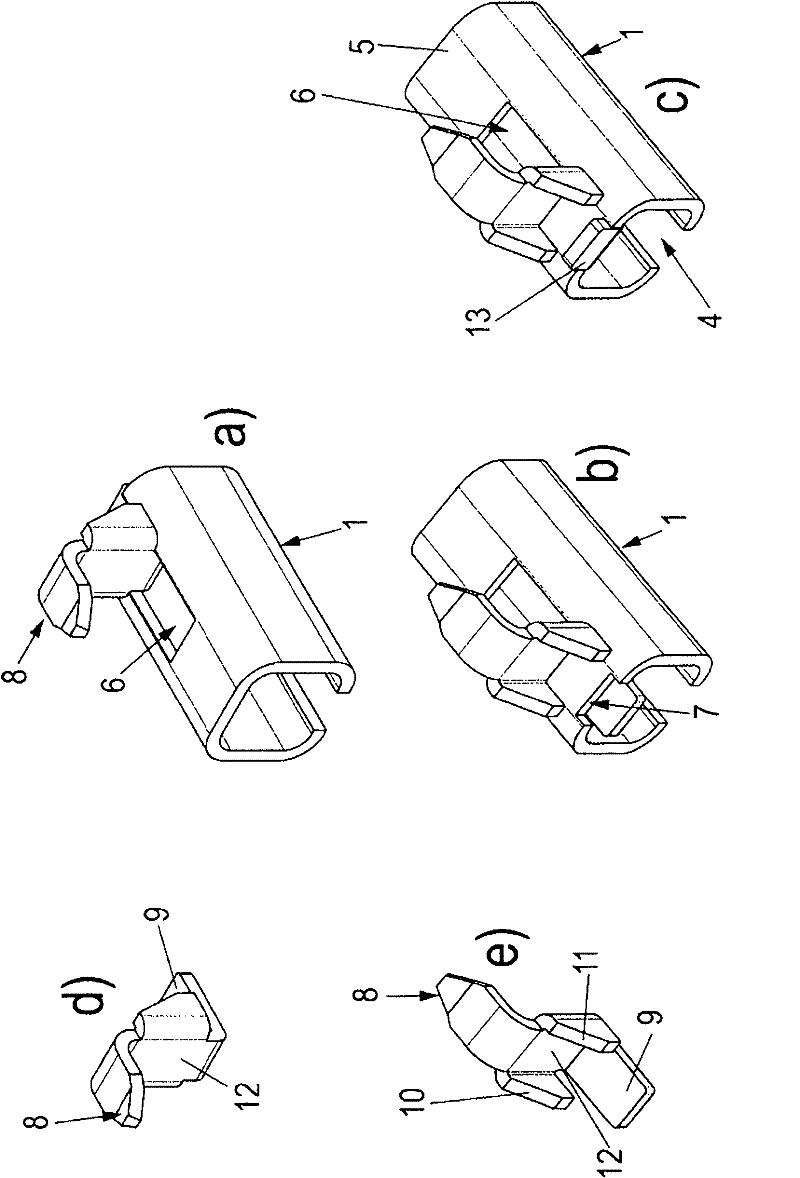

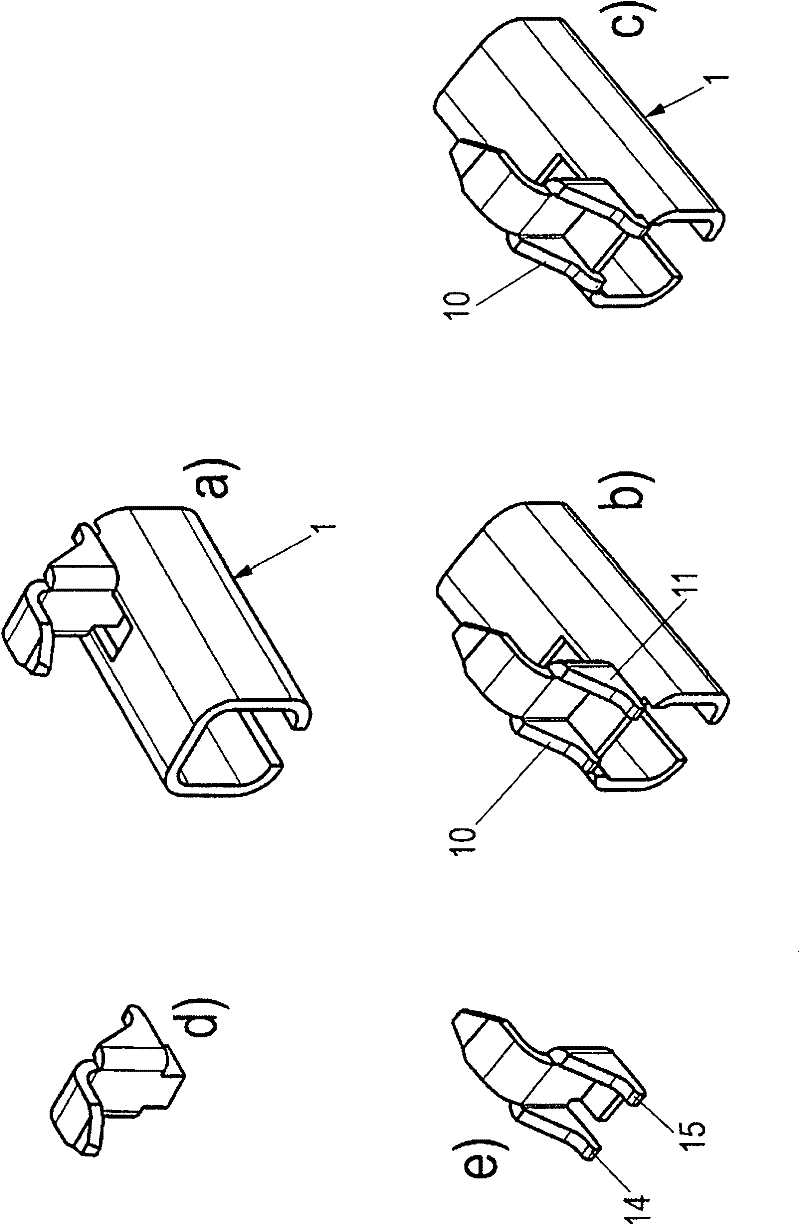

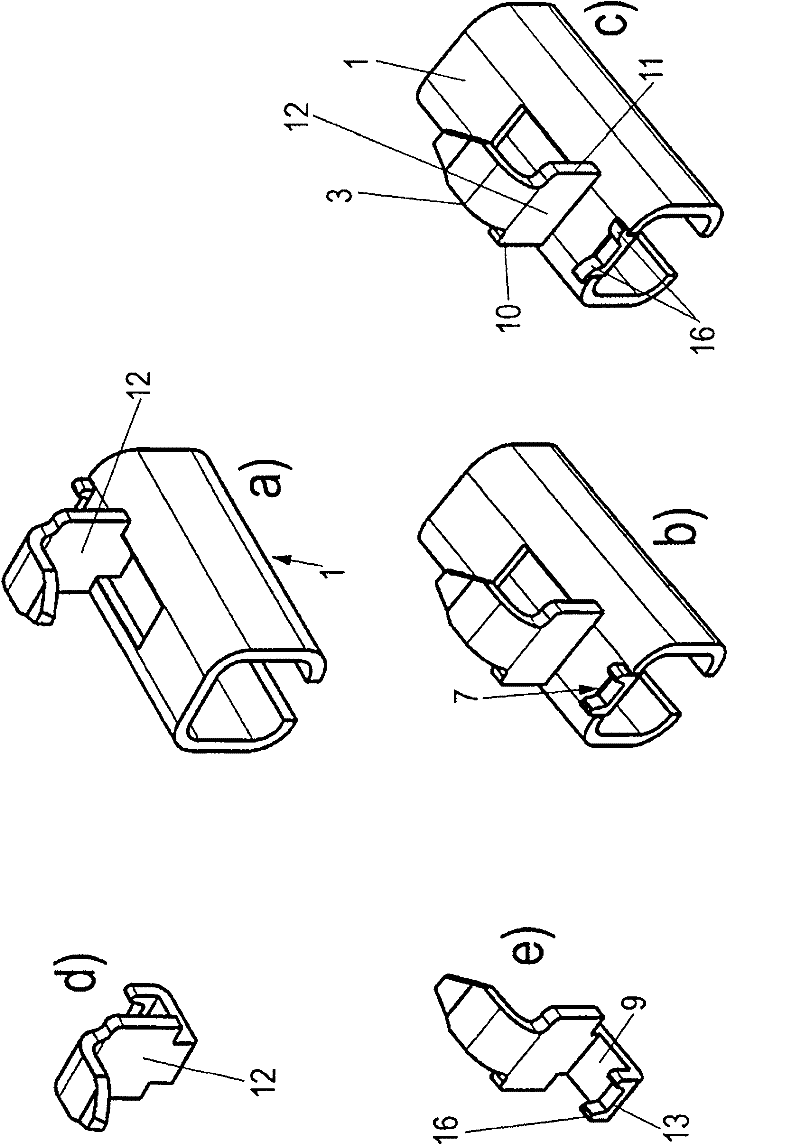

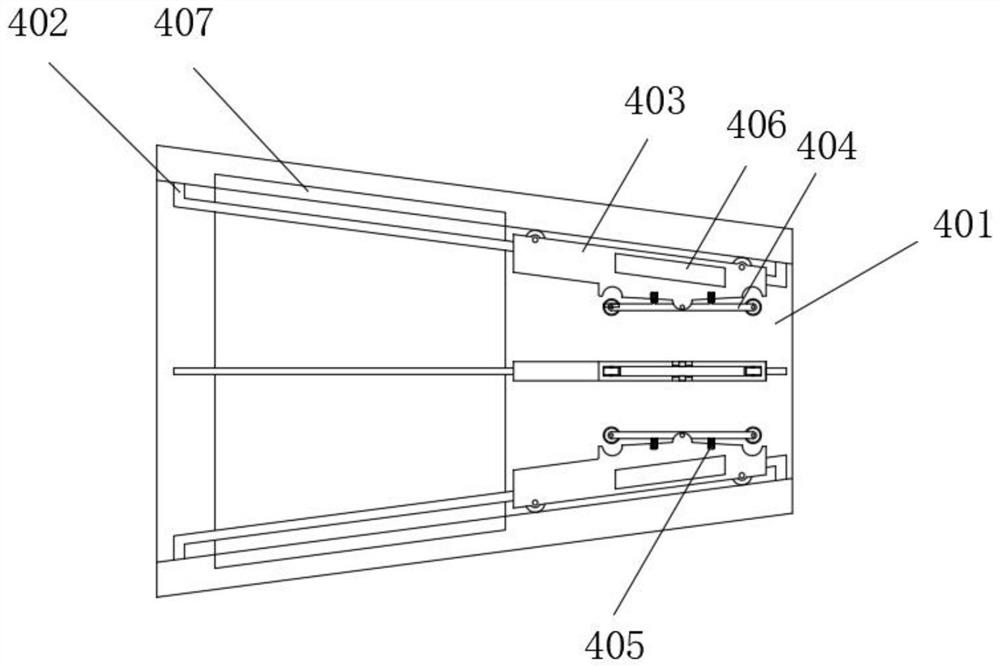

Pull-out guide for drawers, comprising a catch hook

Owner:PAUL HETTICH

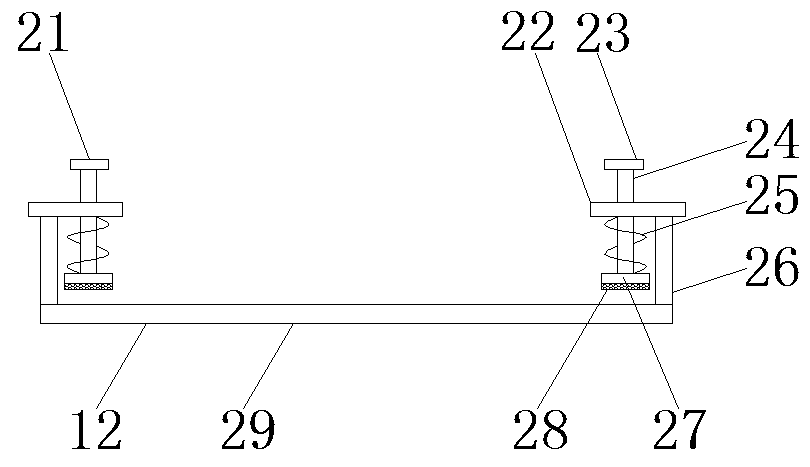

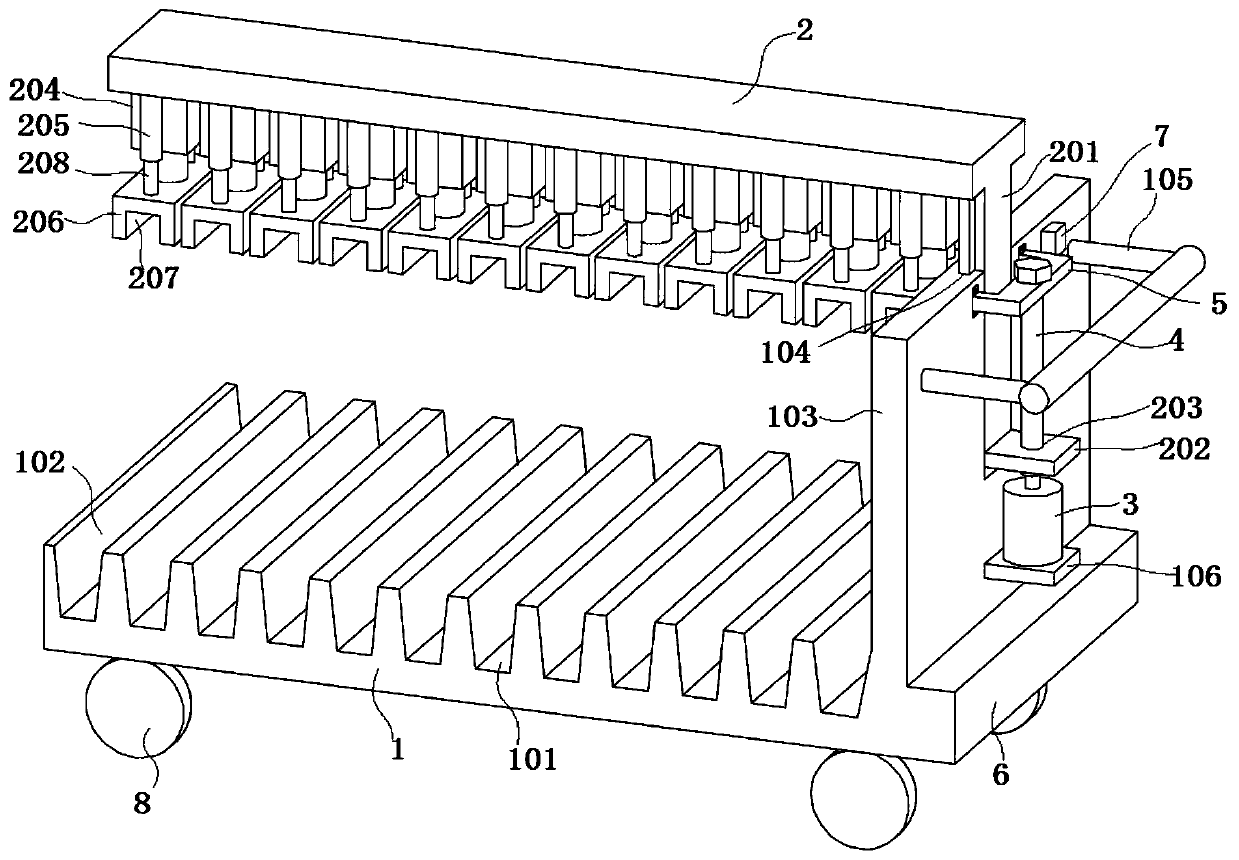

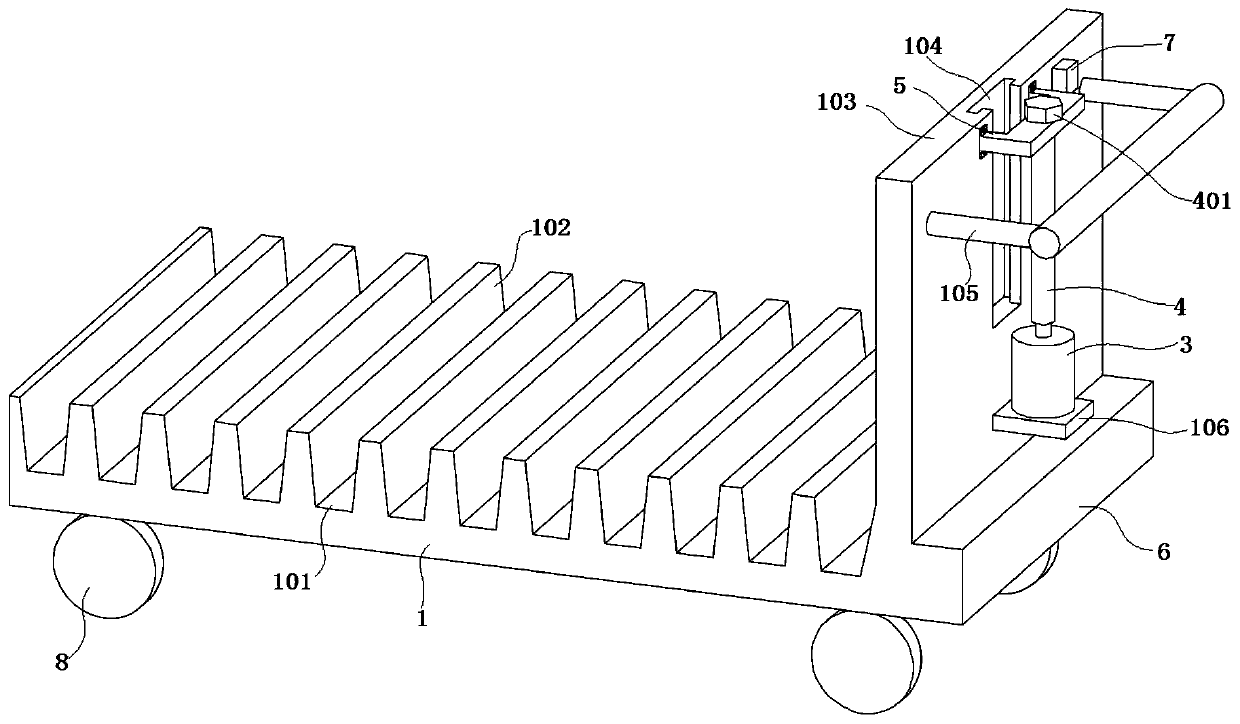

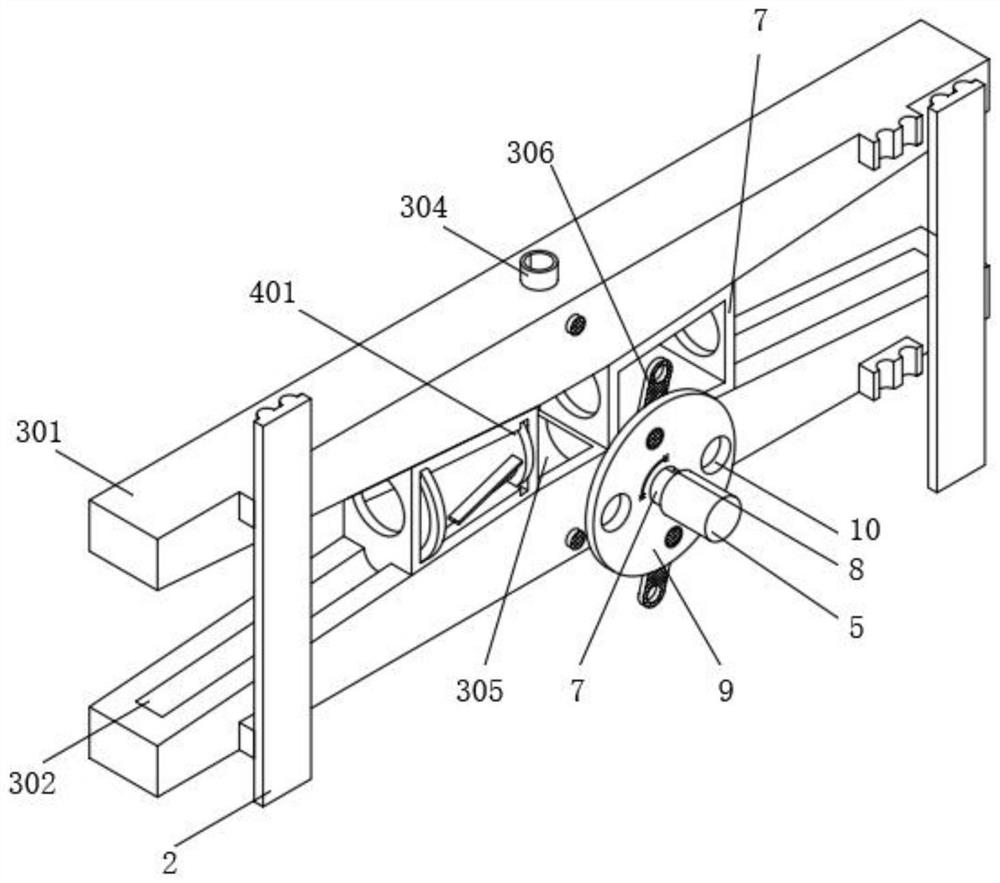

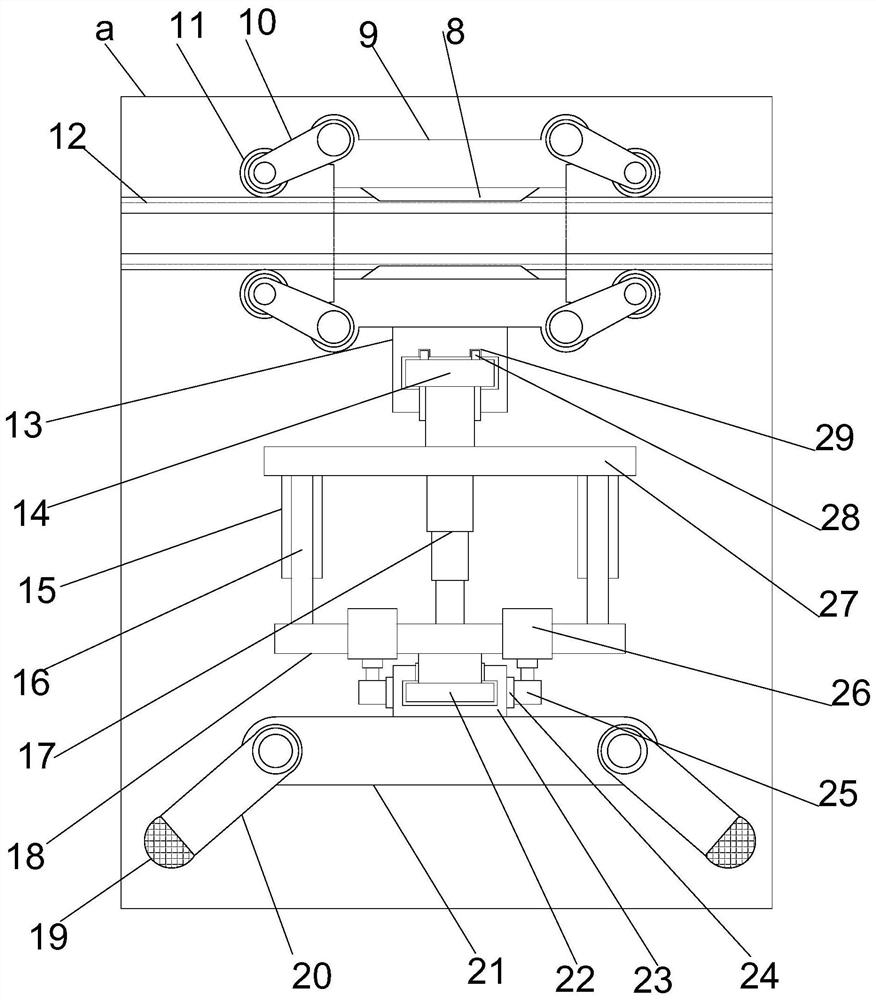

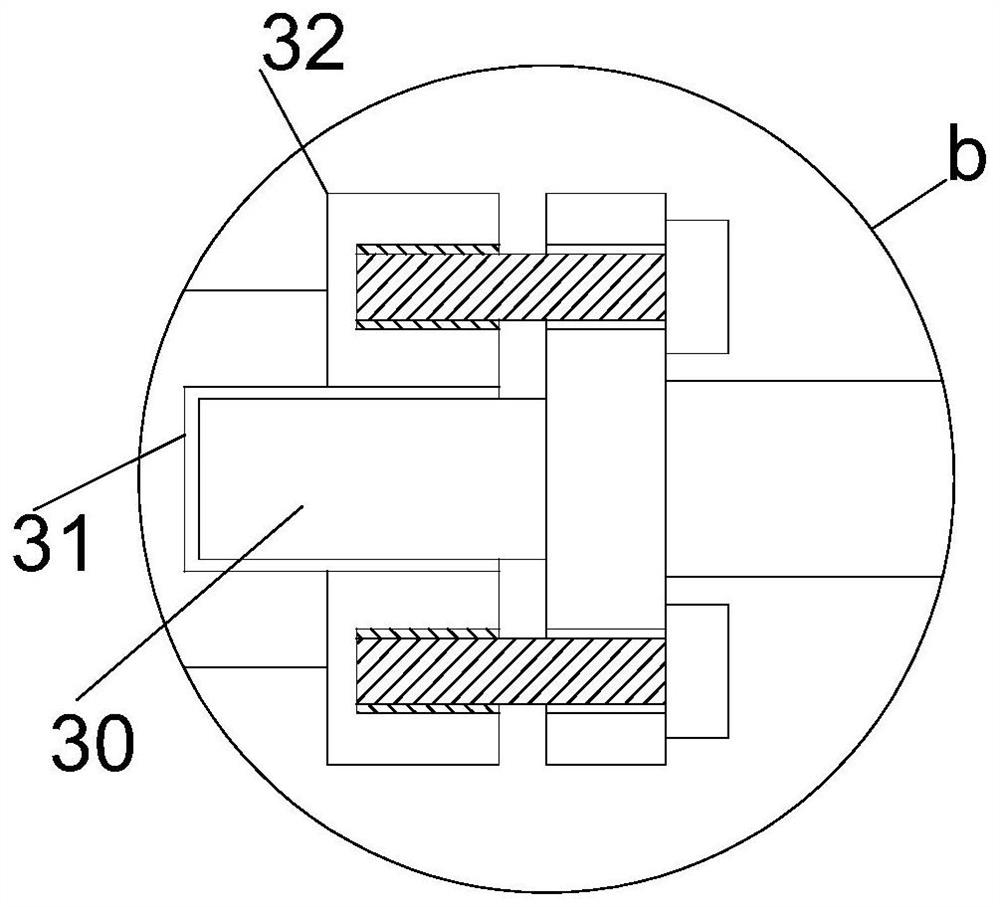

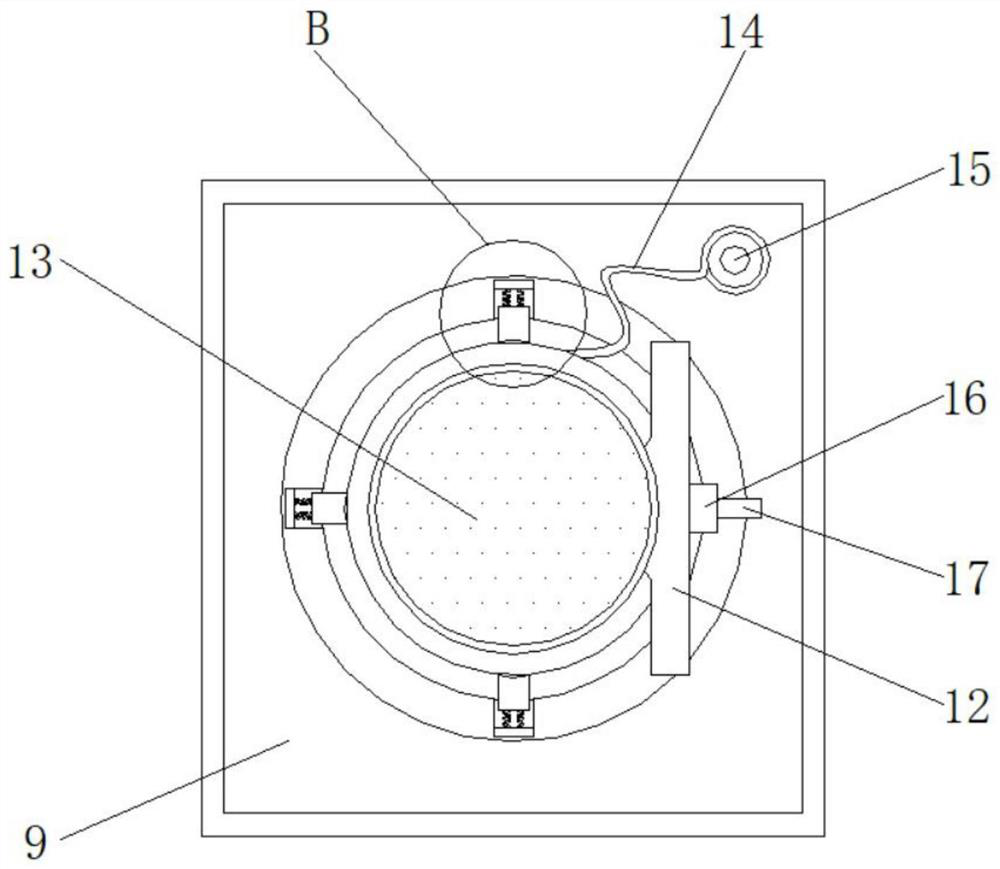

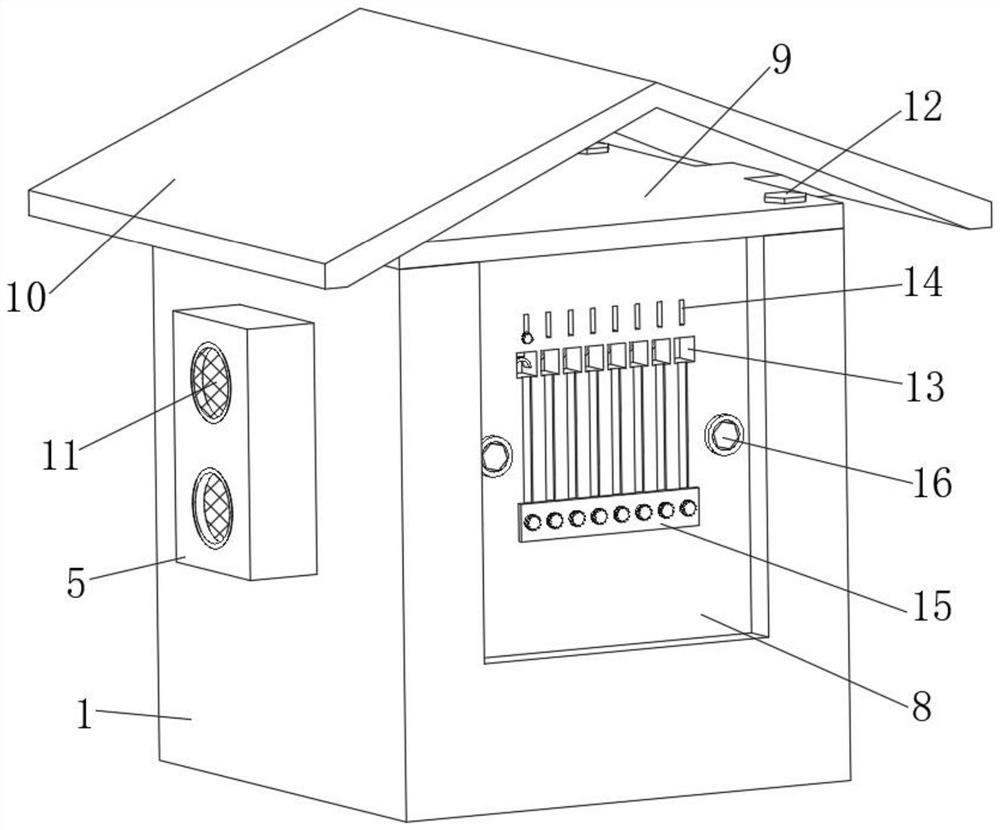

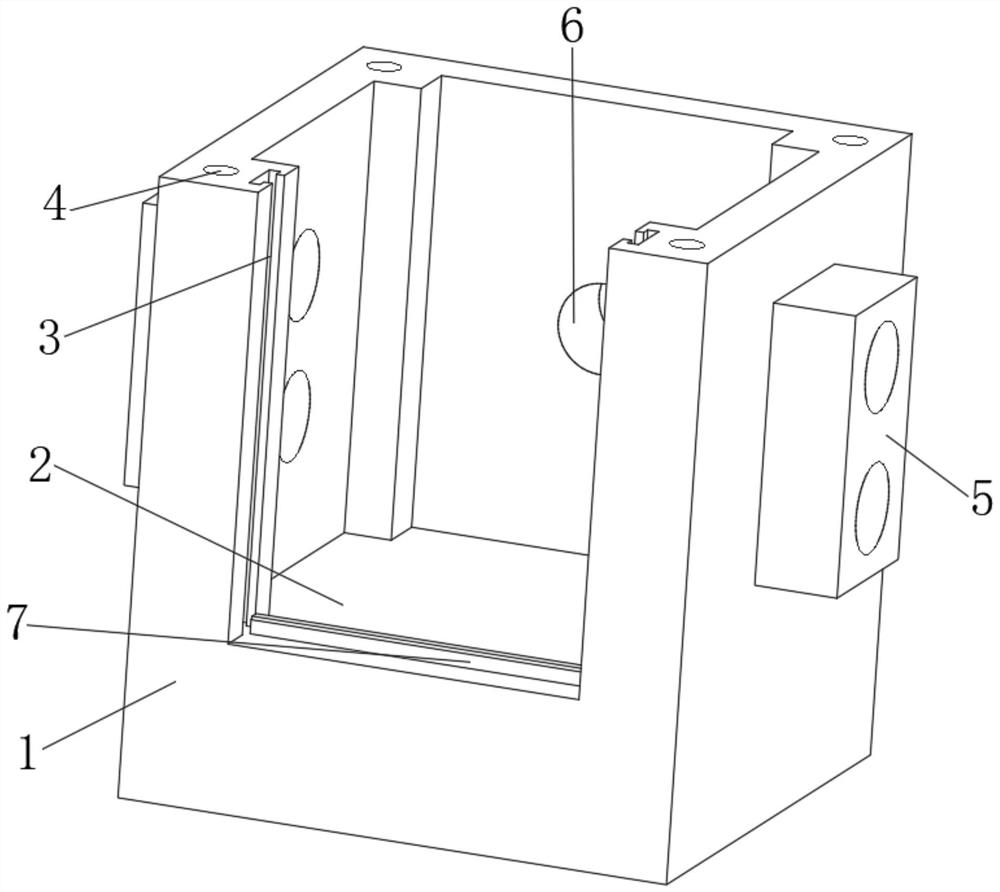

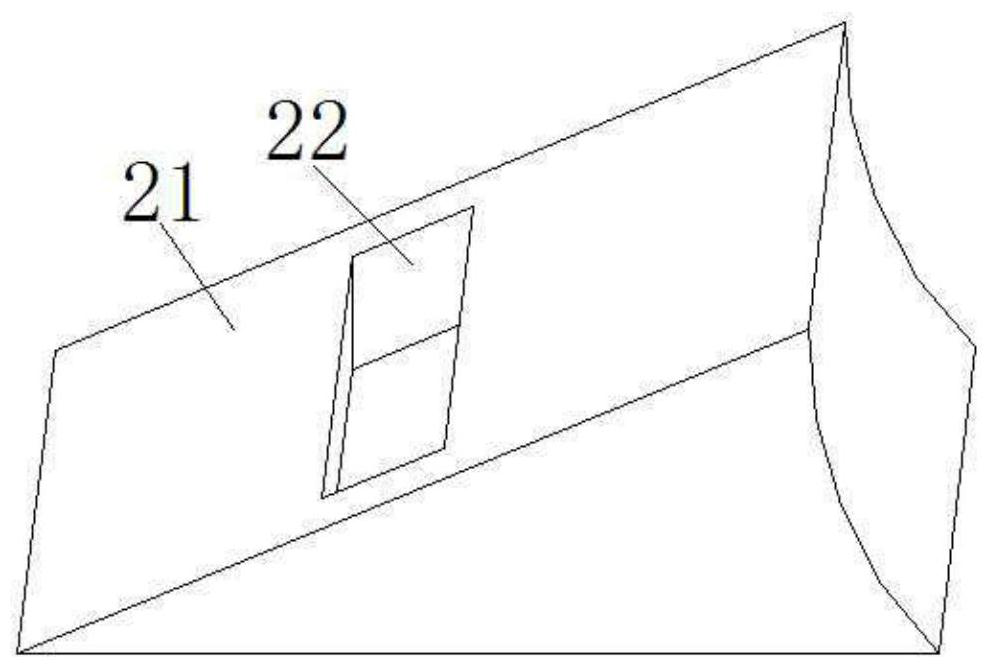

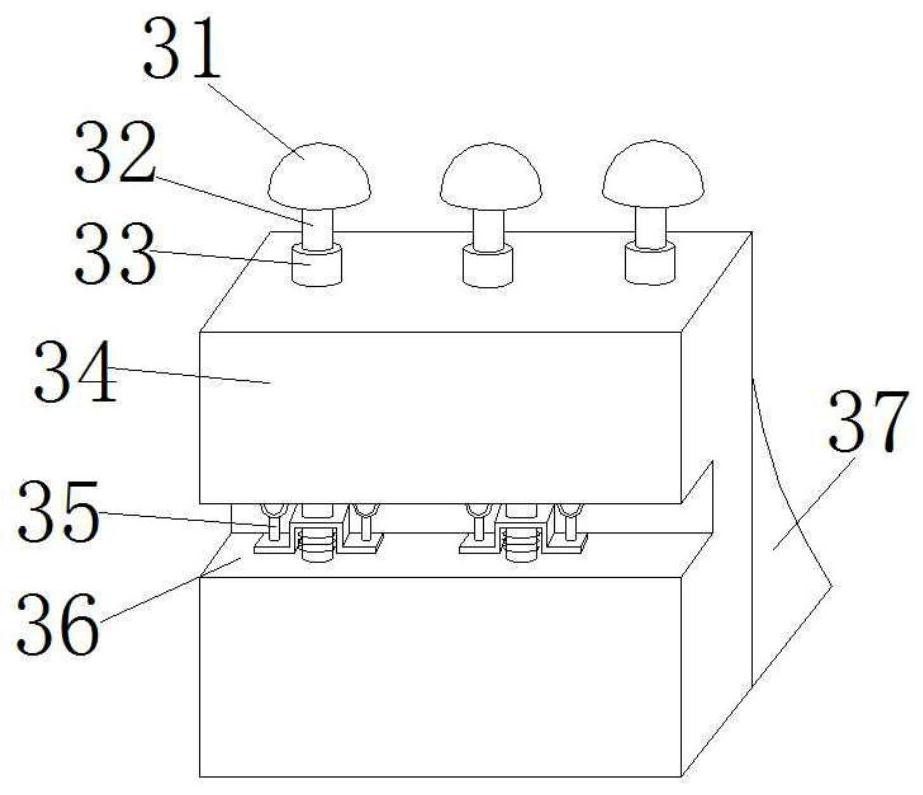

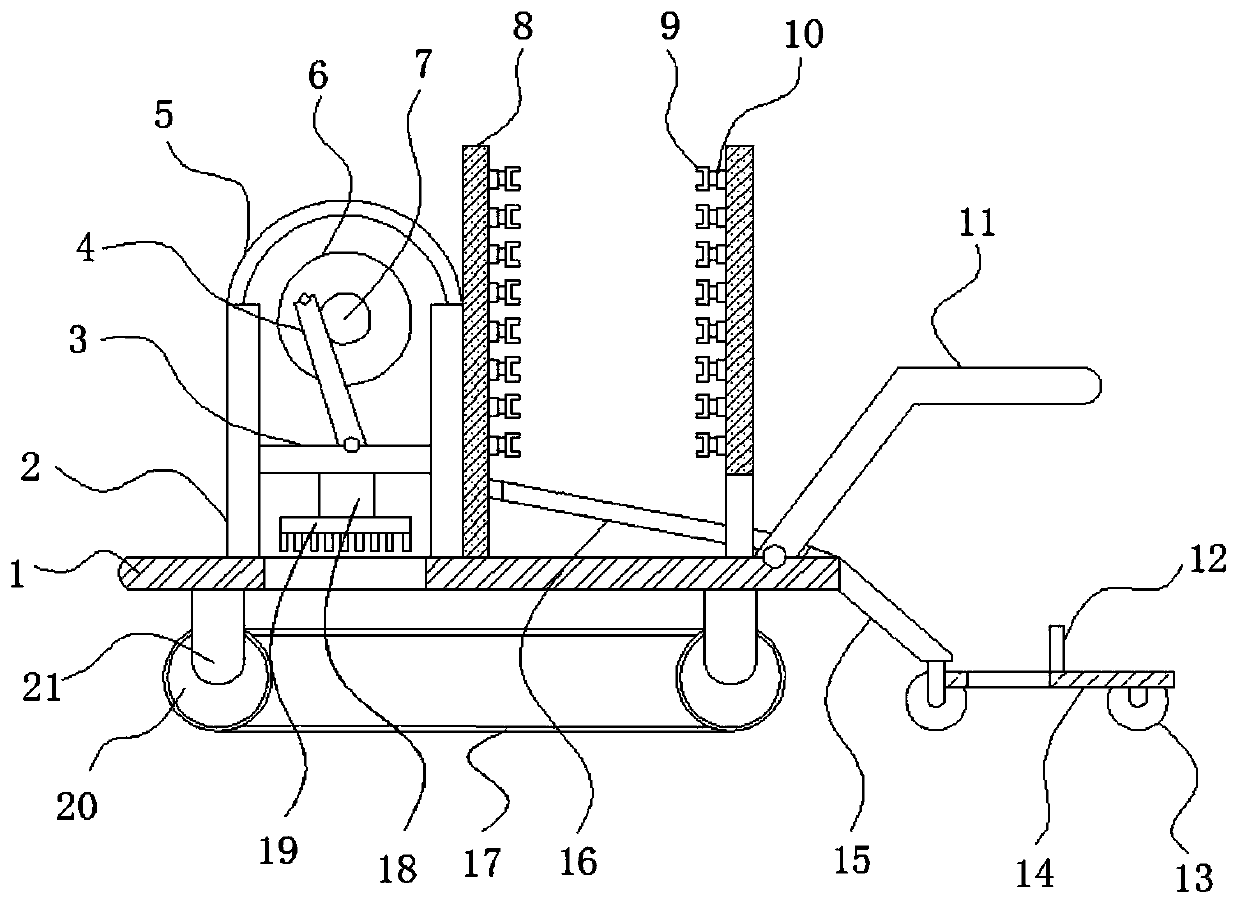

Adjustable transfer trolley for intelligent blackboard production

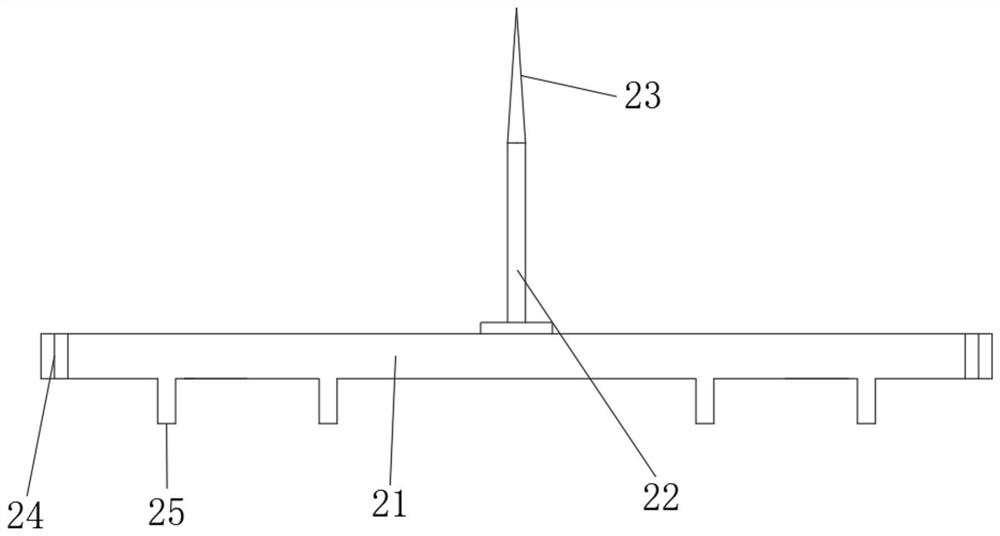

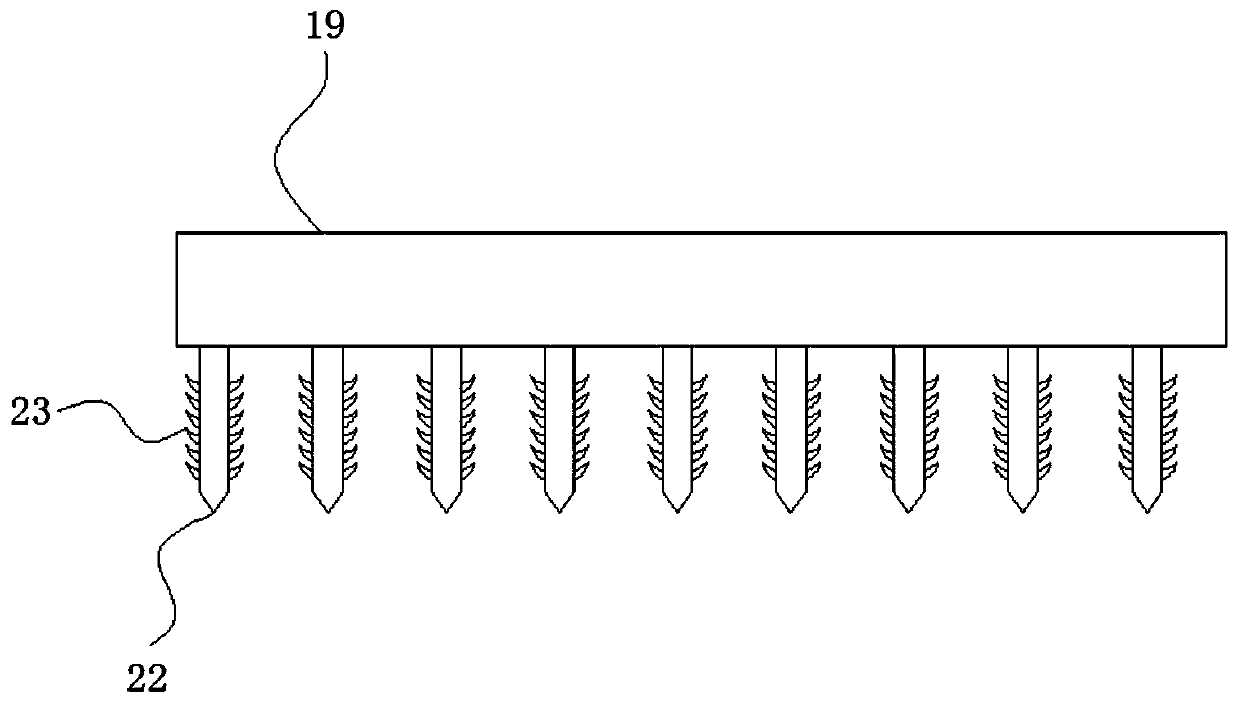

InactiveCN111267924AAchieve fixationAchieve squeeze fixationHand carts with multiple axesHand cart accessoriesElectric machineryEngineering

The invention discloses an adjustable transfer trolley for intelligent blackboard production, and relates to the field of blackboard production. In the invention, a plurality of fixing clamping grooves are formed in the upper surface of a vehicle body side by side, a chute is formed in the middle of the upper end surface of the baffle, a motor is installed below the sliding groove, a screw rod ismounted on a rotating shaft of the motor, a pressing plate is installed on the sliding groove, the motor drives the pressing plate to move up and down along the chute, a plurality of telescopic rods are mounted on the lower surface of the pressing plate side by side, pressing blocks are installed on the lower end faces of the telescopic rods, pressing grooves are formed in the lower end surfaces of the pressing blocks, and the pressing grooves correspond to the fixing clamping grooves. The fixing clamping groove is formed in the upper end face of the vehicle body, and, through cooperate with the pressure groove on the pressure block, the fixing of the blackboard to be transferred is achieved; and the motor and the lead screw structure drive the pressing plate to move up and down, the height can be adjusted according to the size of the blackboard, the pressing block is installed on the pressing plate through the telescopic rod, the adjustable transfer trolley can adapt to blackboards ofdifferent sizes at the same time, and the blackboards of various sizes can be transferred at the same time in the transferring process.

Owner:安徽文香信息技术有限公司

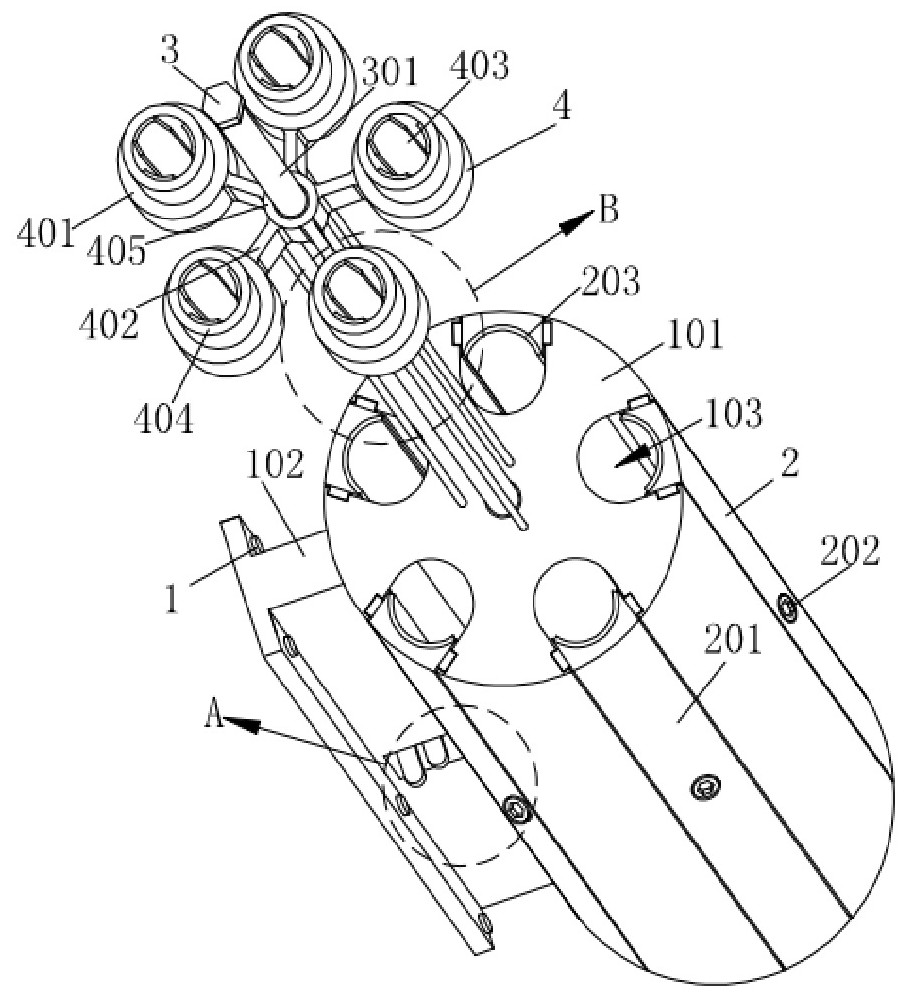

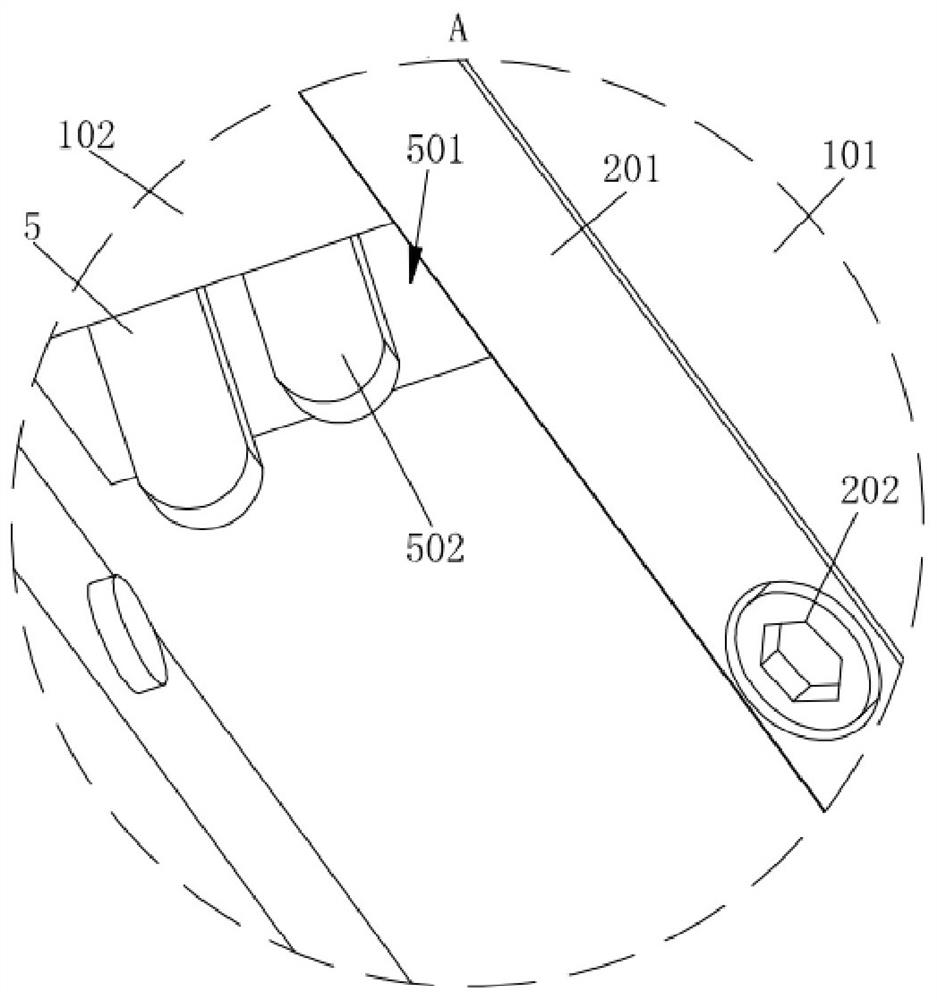

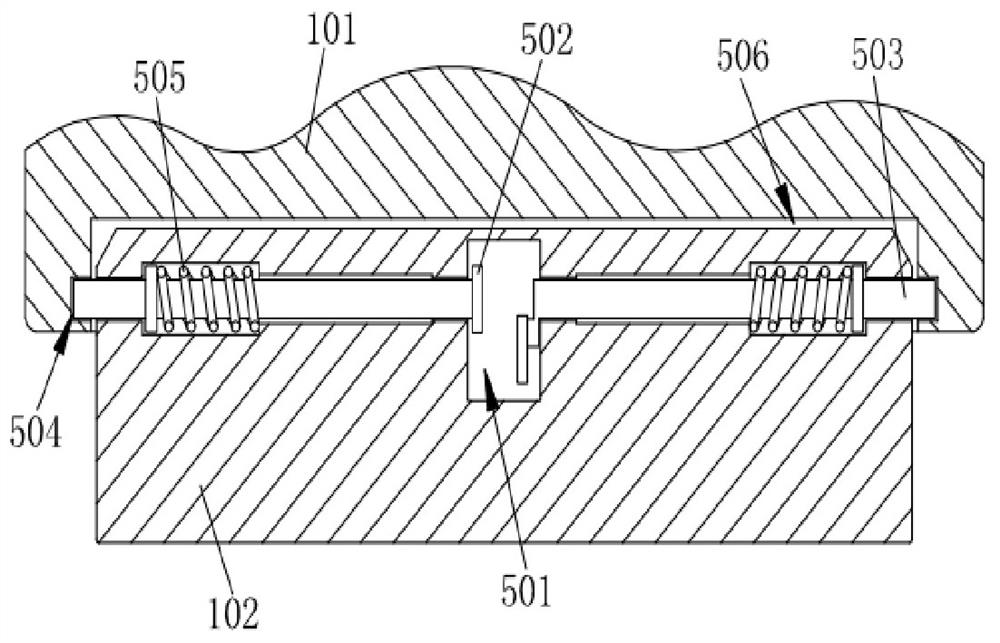

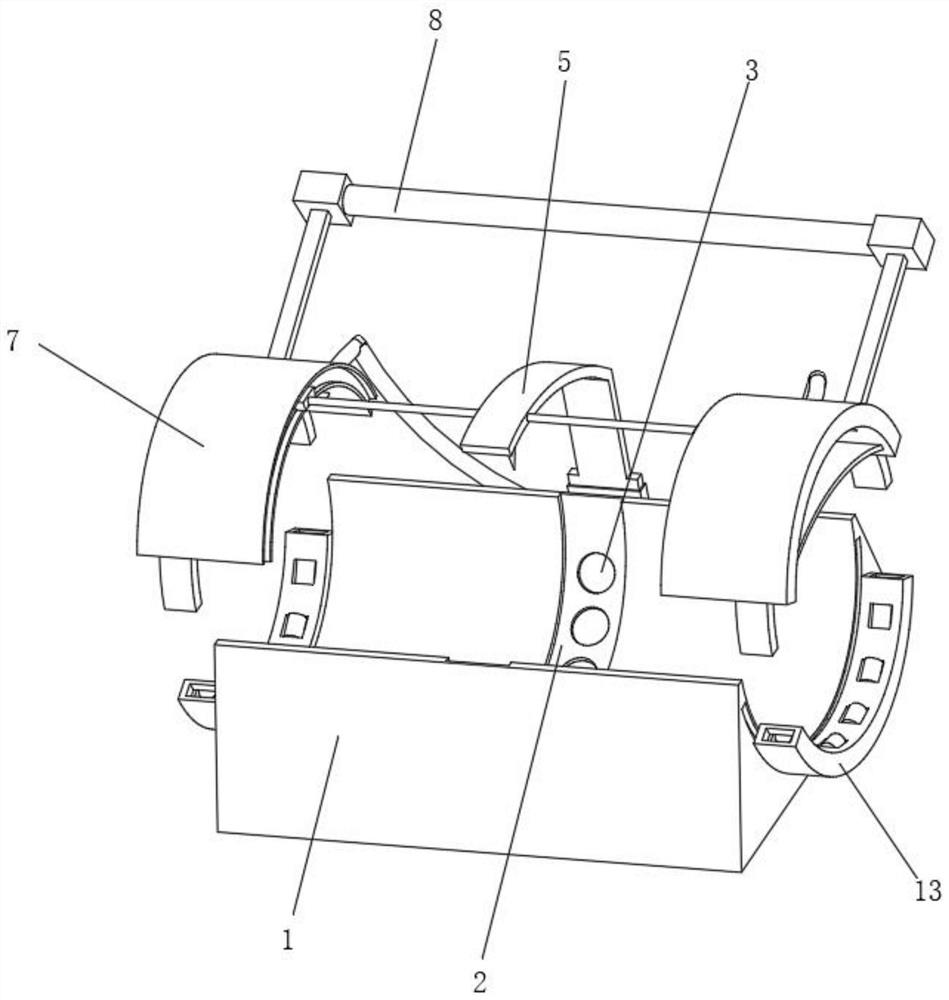

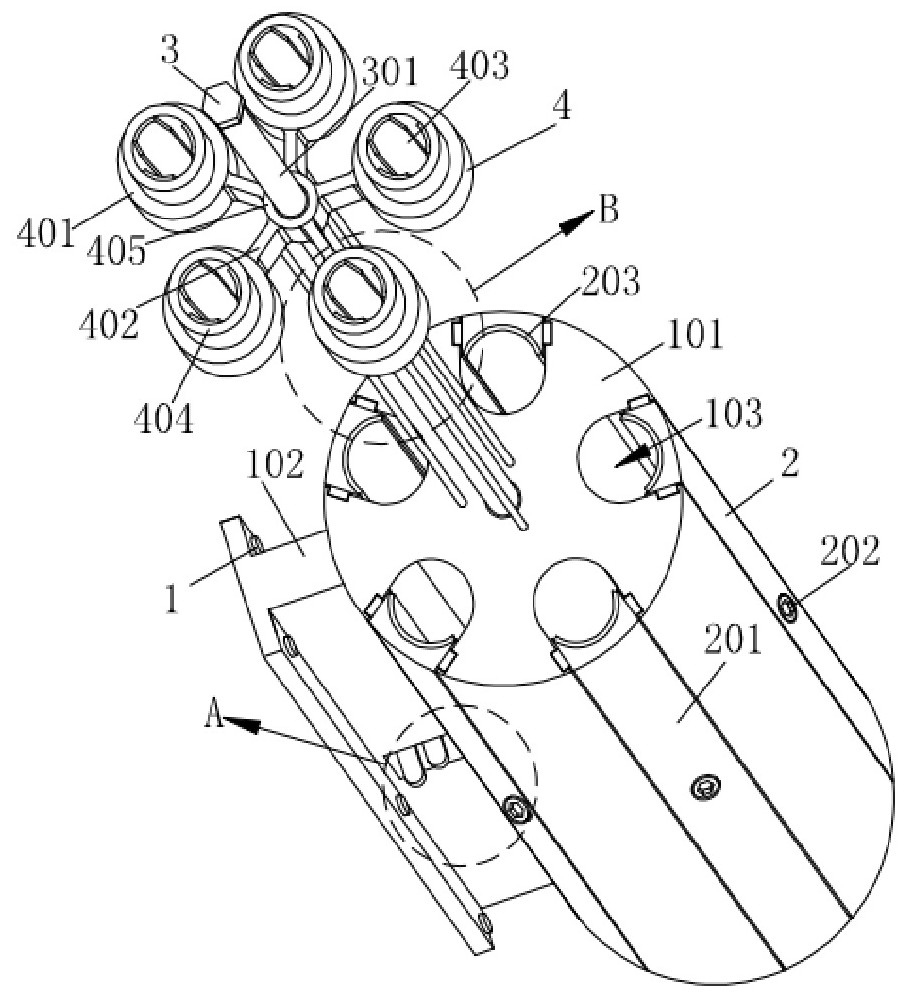

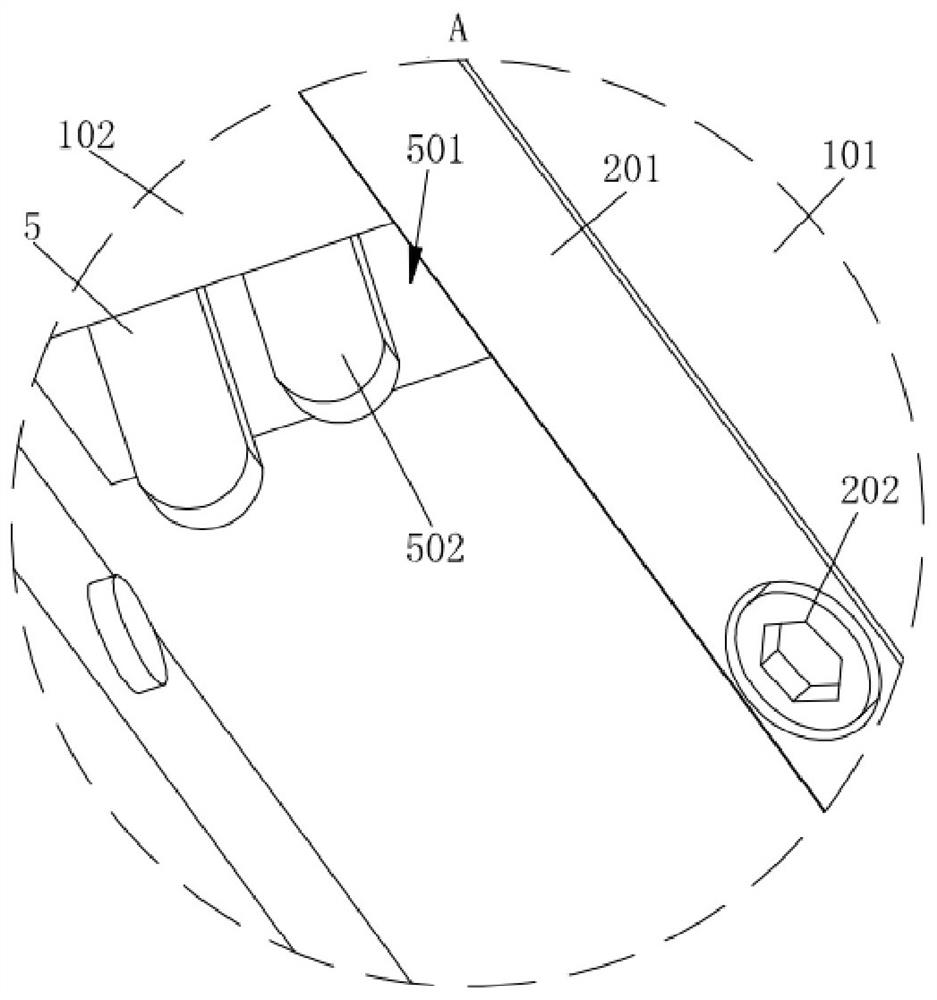

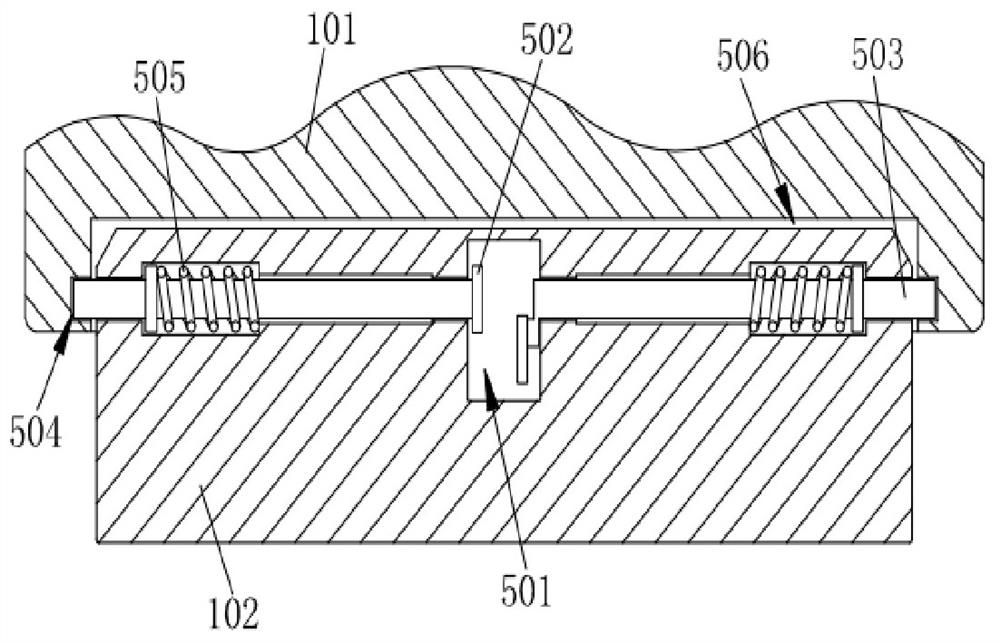

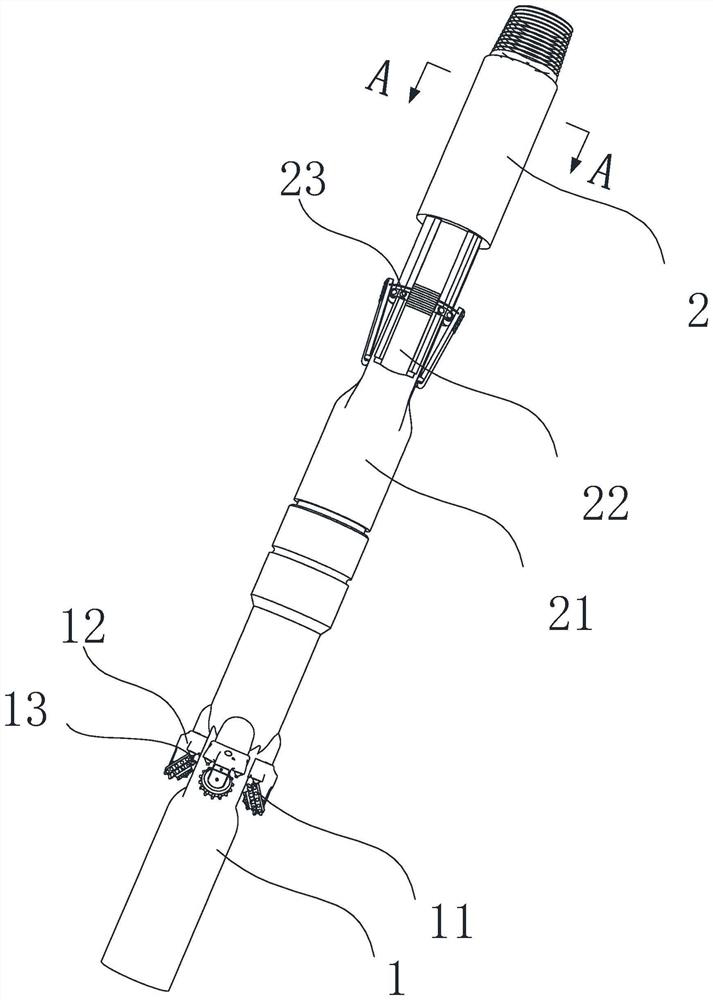

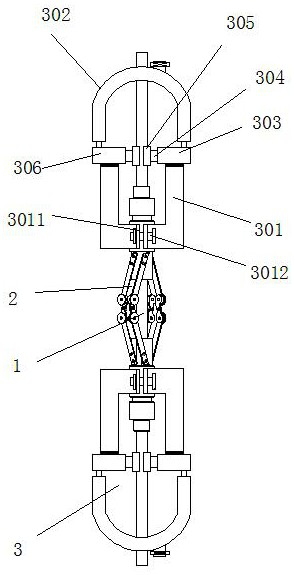

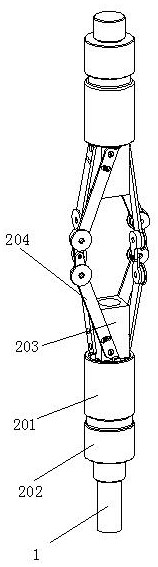

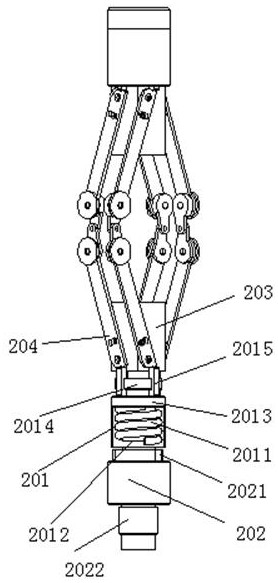

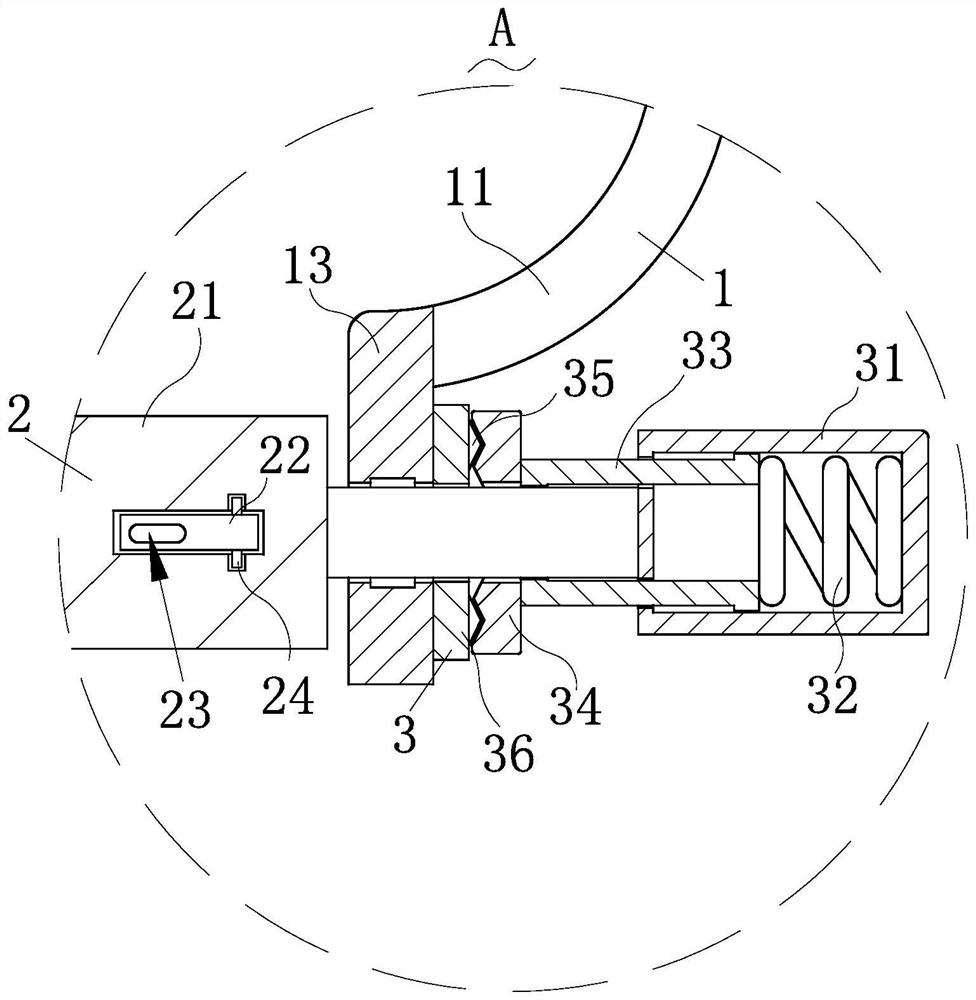

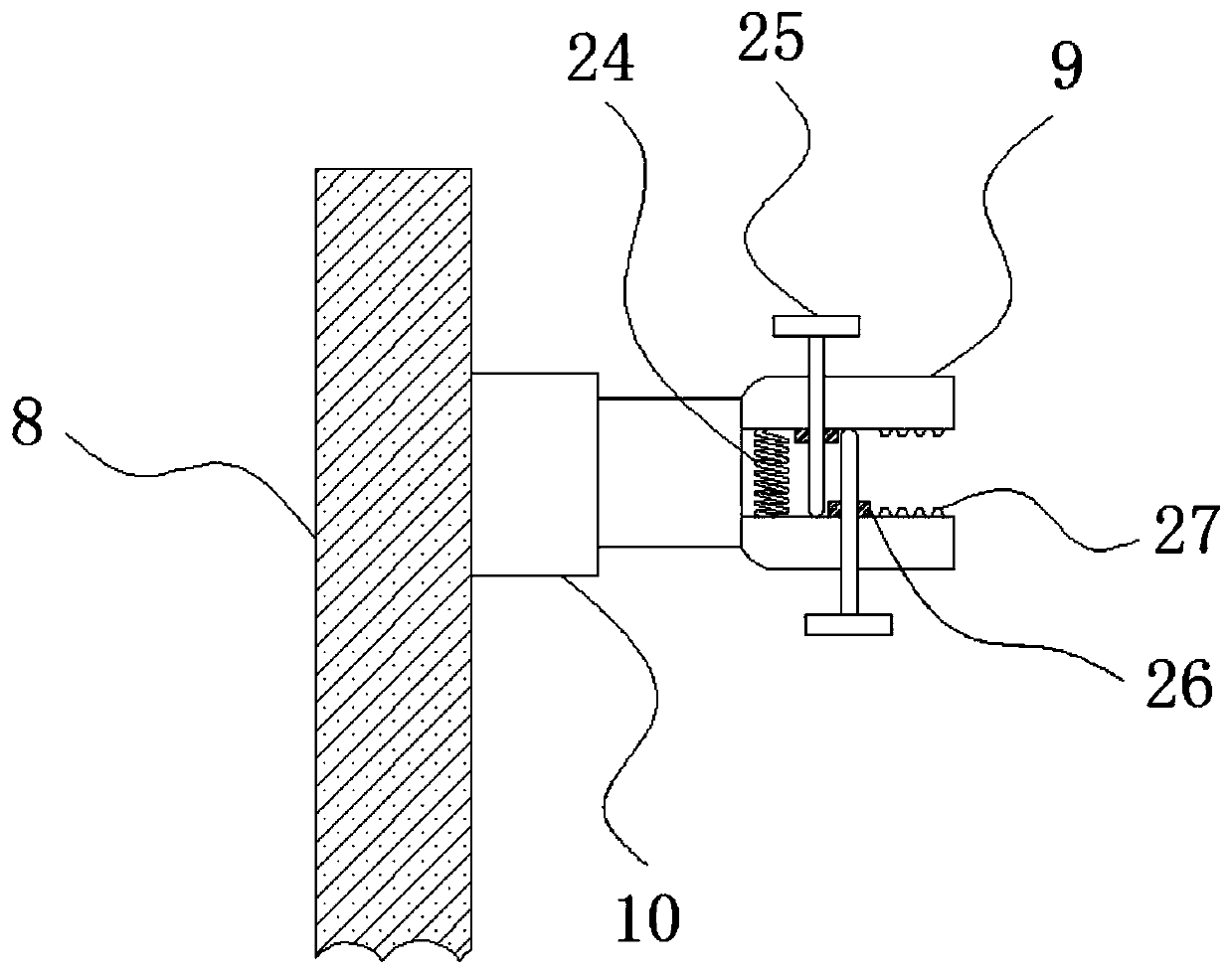

Cable butt joint assembly for intelligent robot

ActiveCN113541086AAvoid strainAvoid breakingRelieving strain on wire connectionCable junctionsStructural engineeringControl theory

The invention relates to the technical field of robot cable butt joint, in particular to a cable butt joint assembly for an intelligent robot. The cable butt joint assemblycomprises a main body mechanism, wherein a plurality of fixing mechanisms for fixing cables are annularly arrayed on the main body mechanism for butt joint of a plurality of cables, a mounting mechanism is arranged on the main body mechanism, a buffering mechanism is arranged on the main body mechanism, an auxiliary mechanism is arranged on the main body mechanism, the auxiliary mechanism is in threaded connection with the buffering mechanism, a clamping mechanism for clamping the cables is installed on the buffering mechanism, the joint of the two cables is fixed to the main body mechanism, one cable is fixed to the clamping mechanism, the cable between the clamping mechanism and the main body mechanism is reserved during installation so as to pull a section of cable between the clamping mechanism and the auxiliary mechanism when the cable is pulled, and the section of cable is protected by the buffering mechanism so as to avoid the cable from being damaged by pulling, so that the joint of the two cables on the main body mechanism is prevented from being broken by pulling.

Owner:江苏润杨机器人有限公司

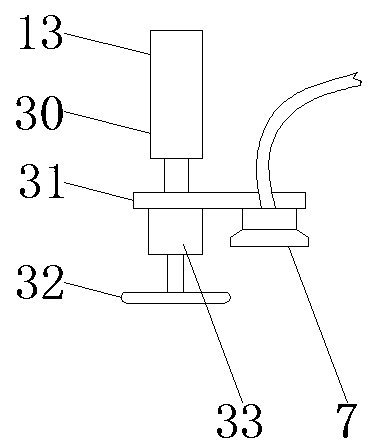

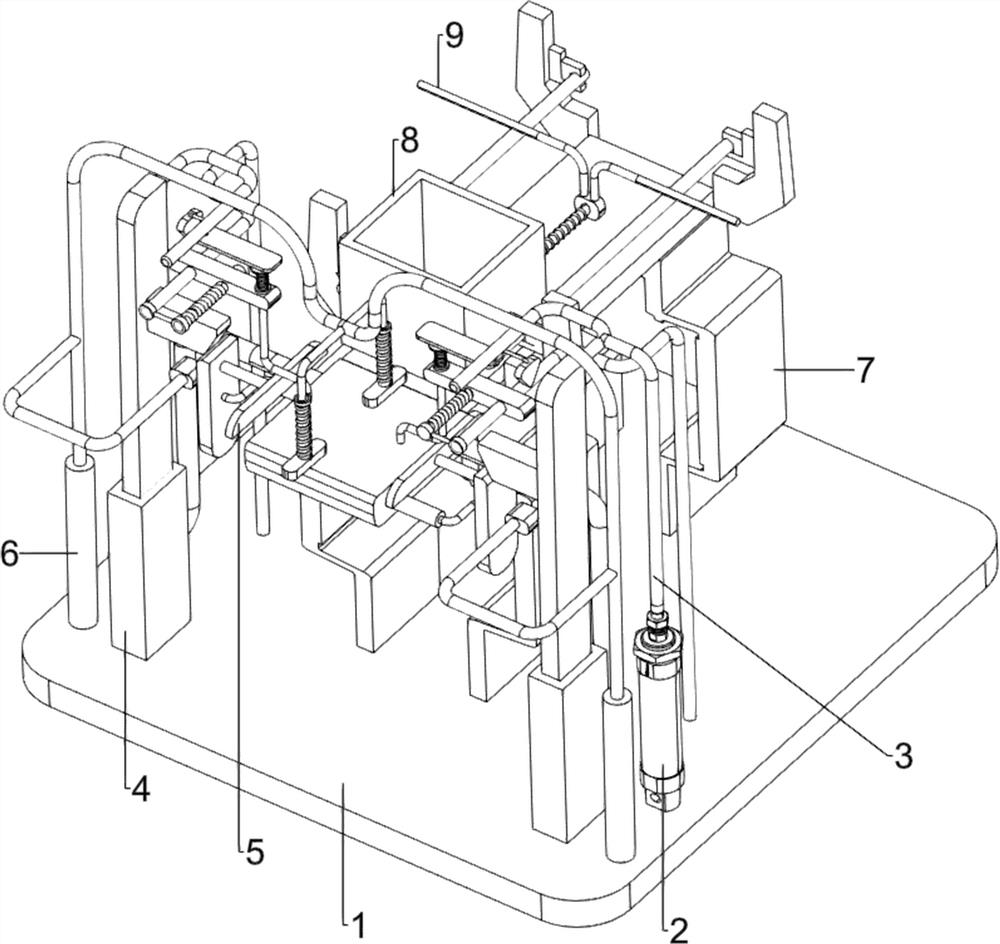

Cable conductor joint welding equipment used in cable production process

ActiveCN114883887AAchieve squeeze fixationAvoid unstable clamping situationsLine/current collector detailsElectrical conductorStructural engineering

The invention relates to the technical field of cable welding, in particular to cable conductor joint welding equipment used in the cable production process, which comprises a mounting plate, sliding rails are arranged on two sides of one end of the mounting plate, a welding mechanism is arranged on the outer sides of the sliding rails, and a servo motor is arranged at one end of the mounting plate. And fans are installed at the positions, located on the two sides of the servo motor, of one end of the mounting plate, and the output end of the servo motor is connected with a rotating shaft. The beneficial effects are that according to the characteristic that the thicknesses of the two sides of the air bag are different, the fluid in the air bag is always bulged after penetrating through the open groove at the thin part when not in use, and when the cable is inserted into the clamping pipe, the fluid is transferred from the extruded direction to the extruded direction according to the trapezoidal structure of the vertical section of the clamping pipe, so that the cable is prevented from being damaged. And finally, the bulging position of the air bag can uniformly and fully cover the outer surface of the cable so as to play a role in fitting and clamping the cable, and when the cable is drawn out, the fluid can return to the thinner position from the thicker position.

Owner:江西科惠达实业有限公司

Welding device

PendingCN112427847APrevent slidingAchieve squeeze fixationWelding/cutting auxillary devicesAuxillary welding devicesPressure generationPhysics

The invention discloses a welding device. The welding device comprises a welding base; a welding regulation and control groove is fixedly connected to the middle of the interior of the welding base; regulation spray holes are evenly formed in the surface of the welding regulation and control groove; an air pressure generation device is fixedly connected to the middle of the back face of the welding base; a welding apparatus is fixedly connected to the top of the air pressure generation device; supporting connecting rods are rotationally connected to the left side and the right side, close to the upper portion, of the welding apparatus; limiting pressing plates are arranged on the two sides of each supporting connecting rod; hand-held control rods are fixedly connected to the sides, close to the back face, of the limiting pressing plates; state adjusting mechanisms are fixedly connected to the middles in the limiting pressing plates; and a touch elastic sheet is fixedly connected to themiddle position of the bottom of the corresponding limiting pressing plate and located below the corresponding state adjusting mechanism. The welding device relates to the technical field of welding.According to the welding device, mechanical driving is achieved by changing the pressure intensity, workers can conveniently change the air pressure state at any time, switching between the pressurization state and the normal pressure state is achieved, and the driving stability is high.

Owner:陈虎

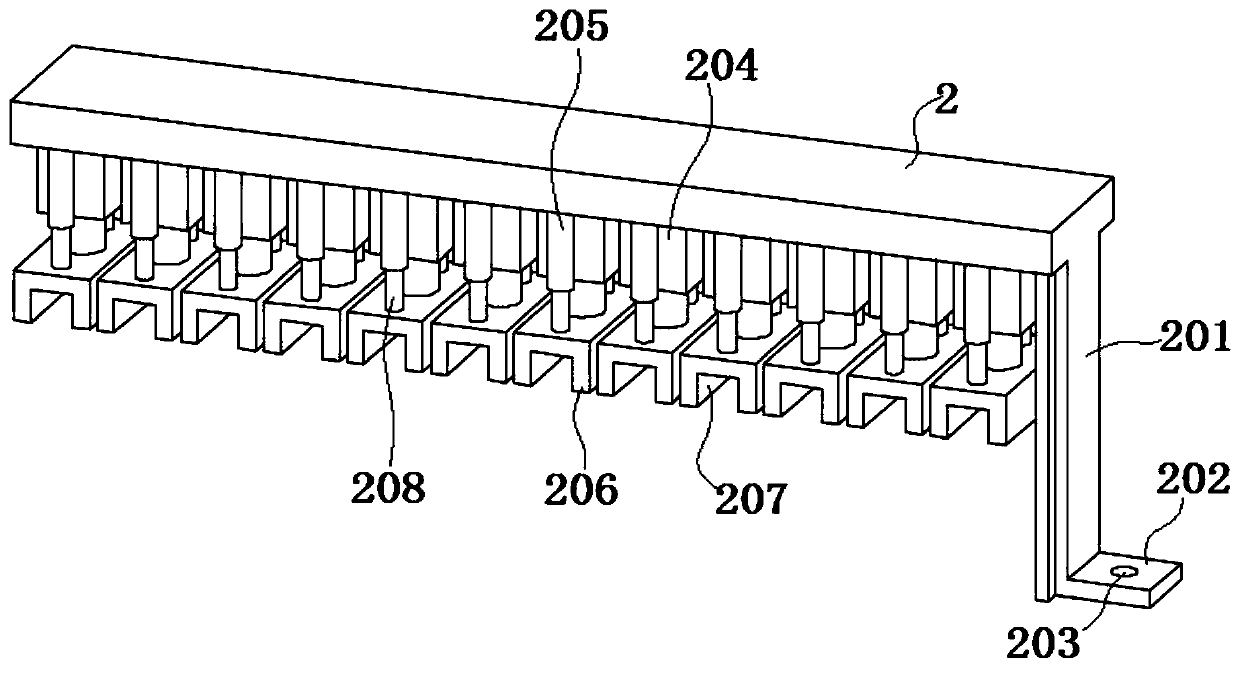

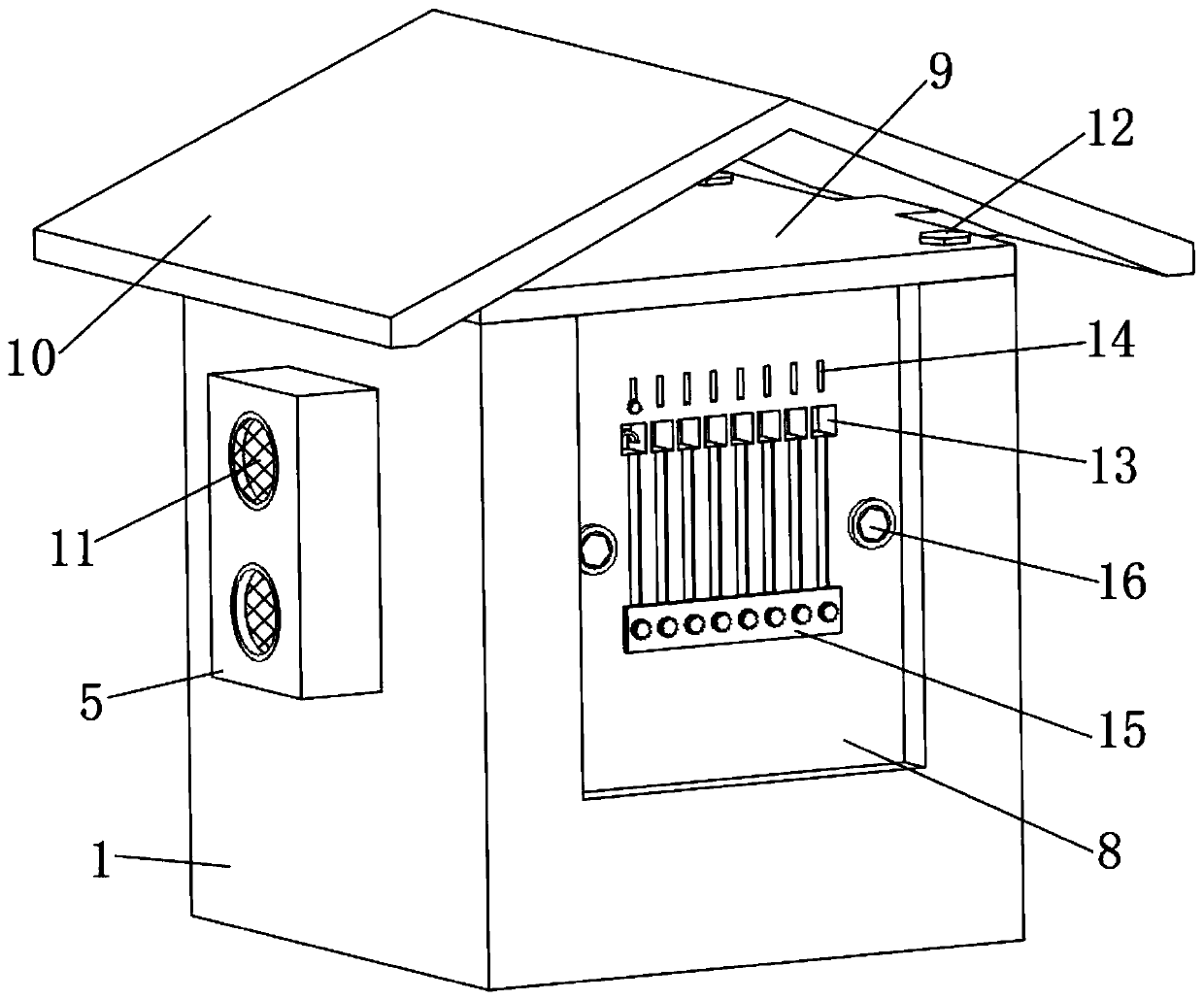

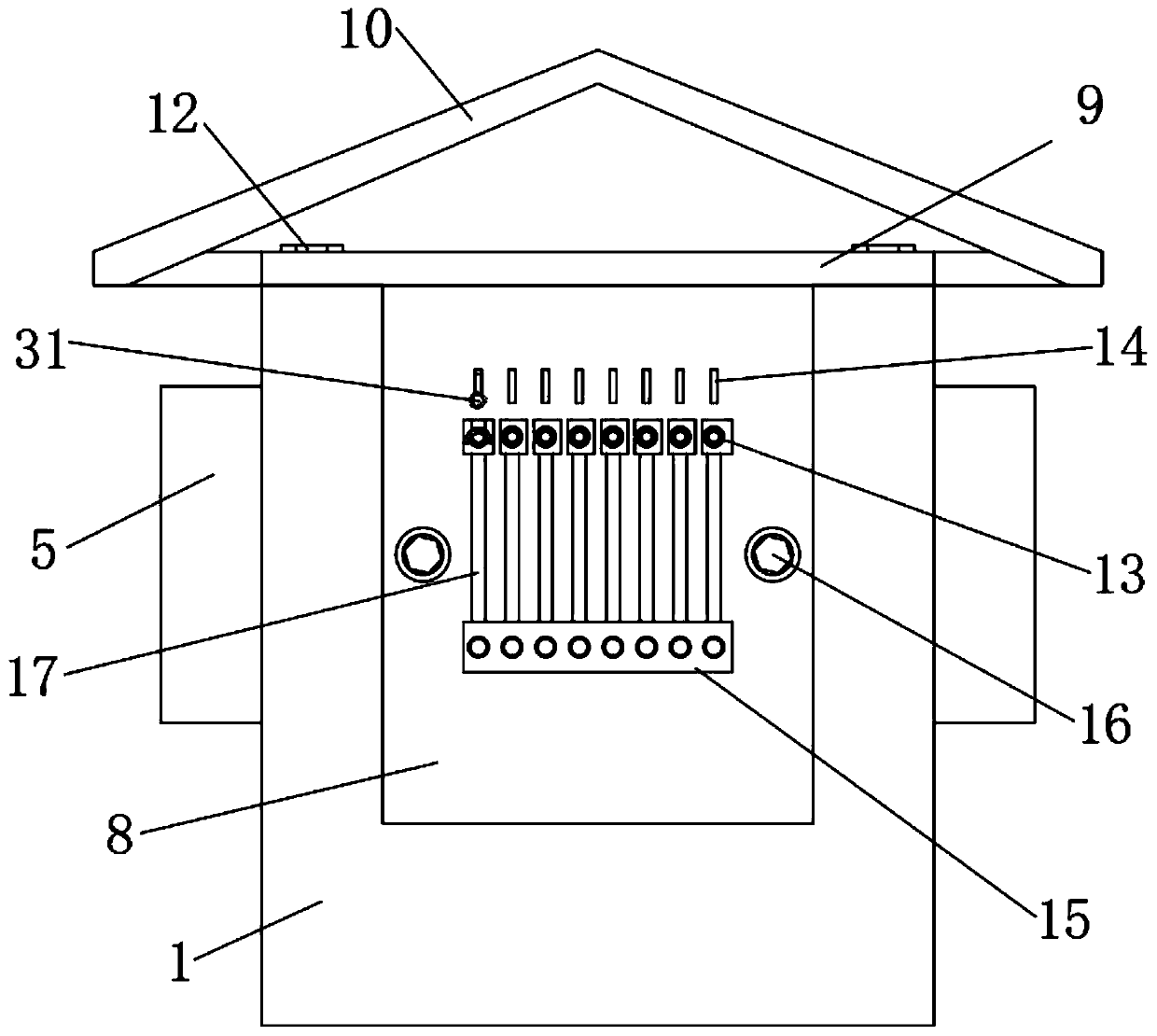

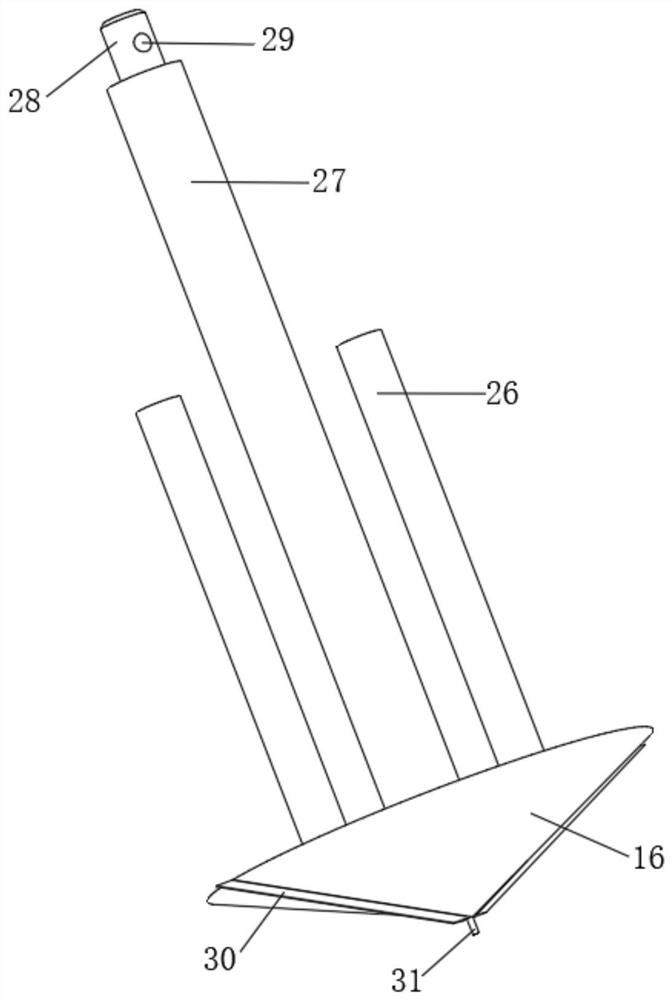

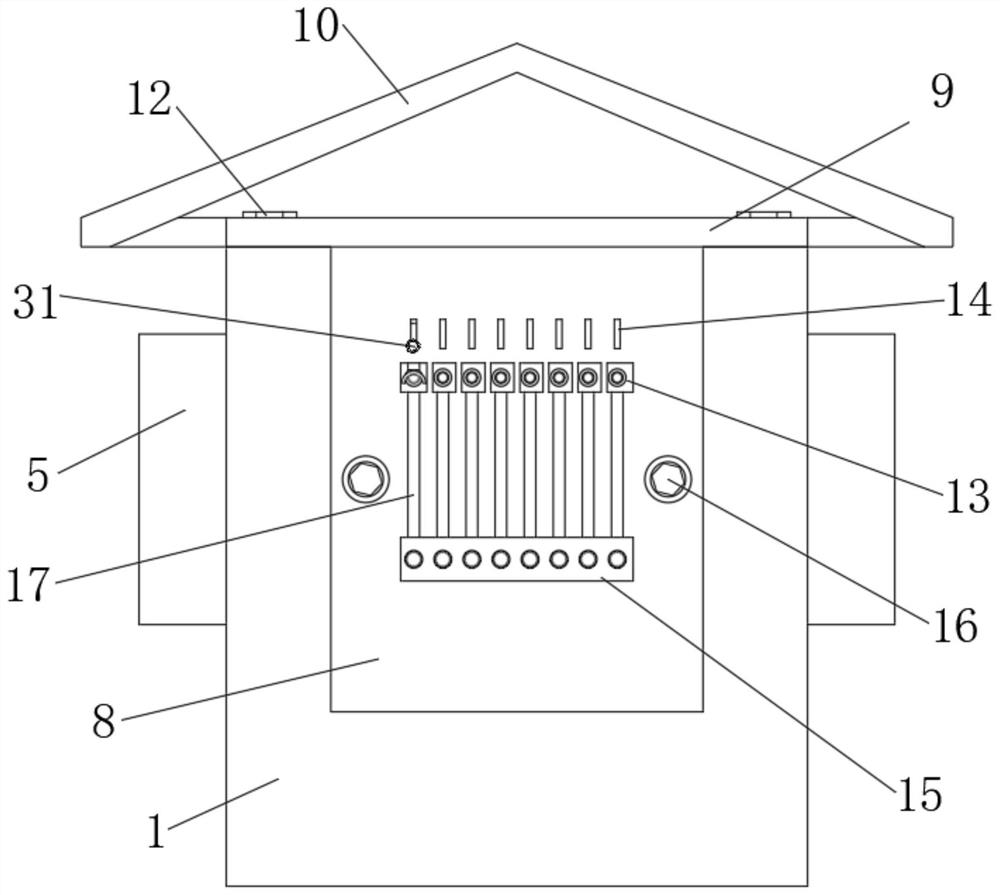

Outgoing line plate arrangement device of power distribution cabinet

ActiveCN111244766ABeautiful distributionNeatly distributedBus-bar/wiring layoutsControl theoryElectric cables

The invention relates to the technical field of power distribution cabinets, and in particular relates to an outgoing line plate arrangement device of a power distribution cabinet. The device comprises a power distribution cabinet. A middle inner cavity of the power distribution cabinet is set as a mounting inner cavity; the outer walls of the left and right sides of the front end face opening ofthe power distribution cabinet are provided with a pair of symmetrical slots; a sealing cover plate is arranged on the upper end face of the power distribution cabinet; and an input jack is formed inthe middle of the rear end face of the power distribution cabinet. The device has the beneficial effects that a cable arrangement inserting plate is additionally arranged; the output position is fixed through the cable arrangement inserting plate, and therefore the purpose of cable arrangement is achieved; cables in the power distribution cabinet are distributed more attractively and tidily, andanalysis and maintenance of a circuit are facilitated; through cooperation of sliding columns with spring extrusion and semicircular clamping blocks, extrusion and fixation of output cables are realized; and through replacement of the models of the clamping blocks, the device is suitable for cables with different thickness specifications, so that the cable arrangement position is further fixed, and falling is avoided.

Owner:CHANGSHU GENERAL ELECTRIC APPLIANCE FACTORY

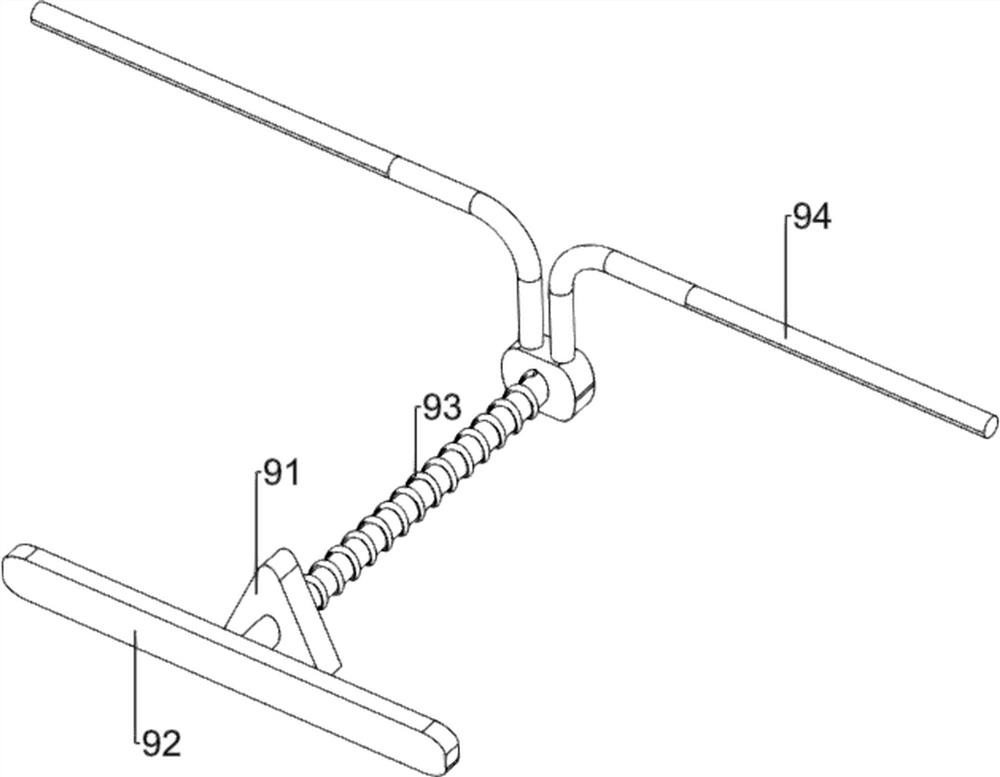

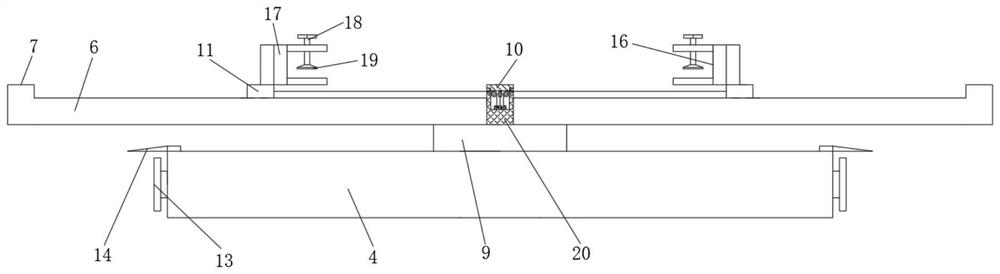

Cable erecting structure of angle steel tower and installation method of cable erecting structure

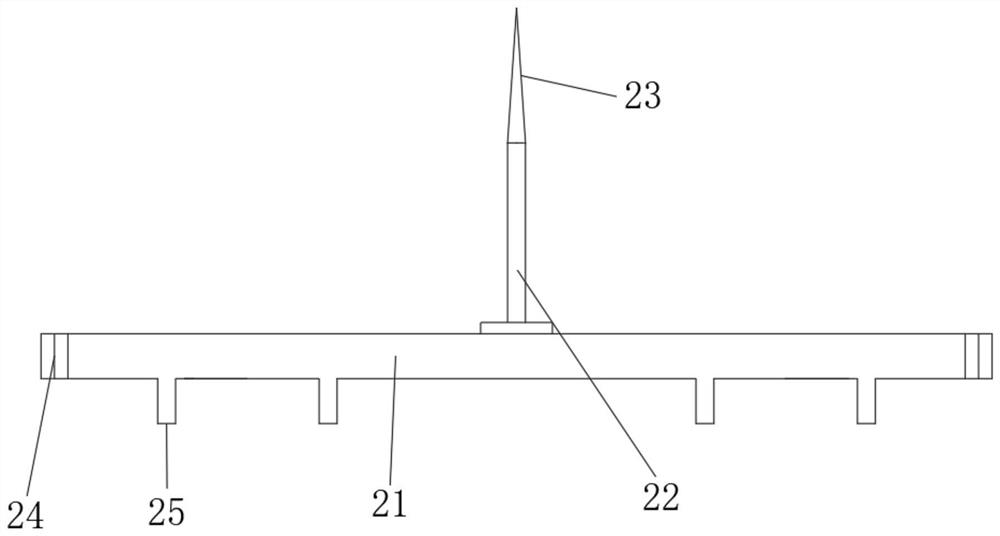

PendingCN113964730AAchieve squeeze fixationInhibit sheddingApparatus for overhead lines/cablesEngineeringTower

The invention relates to the technical field of high-altitude cable erection, in particular to a cable erecting structure of an angle steel tower and an installation method of the cable erecting structure. The cable erecting structure comprises a cross beam, a pair of lower limiting frames in bilateral symmetry are arranged at the lower end of the cross beam, an extrusion wheel driven by an electric telescopic rod is vertically and downwards arranged in the middle of the lower end of the cross beam and a stand column is vertically welded to the right side of the lower end of the cross beam. The cable erecting structure has the beneficial effects that a limiting wheel and a lifting block which are driven by an extrusion screw rod are arranged to be matched, so that a cable is extruded and fixed, meanwhile, the cable is bent and staggered at the extrusion position by utilizing an arc-shaped extrusion groove, the clamping stability is further improved, and the cable is prevented from falling off; and through the arrangement of the stand column and a balancing weight with the adjustable gravity, the stress at the two ends of the cable is balanced when force is applied for straightening, the situation that the cable inclines towards one side due to uneven stress is avoided, therefore, under the action of the electric telescopic rod, constant-speed straightening is achieved, the cable is evenly stressed, and protection on the outer wall of the cable is greatly improved.

Owner:新昌县银邦电力科技有限公司

A cable docking assembly for an intelligent robot

ActiveCN113541086BAvoid strainAvoid breakingRelieving strain on wire connectionCable junctionsControl engineeringElectric cables

The invention relates to the technical field of robot cable docking, in particular to a cable docking assembly for an intelligent robot, including a main body mechanism, and a plurality of fixing mechanisms for fixing cables are arranged in a circular array on the main body mechanism for docking multiple cables , the main mechanism is provided with a mounting mechanism, the main mechanism is provided with a buffer mechanism, the main mechanism is provided with an auxiliary mechanism, the auxiliary mechanism is threaded with the buffer mechanism, and the buffer mechanism is installed with The clamping mechanism for clamping the cables fixes the connection of the two cables with the main body, fixes one of the cables with the clamping mechanism, and reserves the cables between the clamping mechanism and the main body during installation, so that In order to pull a section of cable between the clamping mechanism and the auxiliary mechanism when the cable is pulled, and the buffer mechanism protects this section of cable, avoiding cable damage, thereby avoiding the connection of two cables on the main mechanism. was pulled off.

Owner:江苏润杨机器人有限公司

Breakage-proof perforating device for protective clothing

ActiveCN112518879AEasy to replaceEasy to adjustSevering textilesMetal working apparatusEngineeringStamping process

The invention relates to the technical field of protective clothing processing, in particular to a breakage-proof perforating device for protective clothing. The device comprises a perforating processing table, wherein a concave perforating inner cavity is formed downward in the middle of the upper end face of the perforating processing table, a pressure bearing ring is arranged at the upper end of the perforating processing table, and side plates are symmetrically and vertically welded to the left side and the right side of the upper end face of the perforating processing table. The breakage-proof perforating device for protective clothing has the beneficial effects that by matching the pressing ring with the pressure bearing ring, textile silk threads around the perforating position of protective clothing are extruded and fixed, so that stretching of the silk threads in the perforating and stamping process is reduced, the stretching force between the silk threads is reduced, the deformation degree of the broken silk threads is reduced, and the perforating quality is greatly improved; by arranging a positioning needle, the perforating position is accurately positioned, and meanwhile, the perforating position is opened by inserting the positioning needle into the protective clothing, subsequent chambering and cutting are greatly facilitated, the perforating position precision is improved, the perforating and cutting convenience is improved, and the extrusion force is reduced.

Owner:潍坊坤泽尔安全防护用品有限公司

Pneumatic hip joint rehabilitation training equipment

InactiveCN107714393AImprove comfortEasy to operatePneumatic massageChiropractic devicesEngineeringRehabilitation training

The invention discloses a pneumatic hip joint rehabilitation training device, which comprises a base, a seat plate arranged on the top of the base, a backrest and a headrest, fixed baffles are arranged on both sides of the seat plate, and a fixed baffle is connected to the fixed baffle. A telescopic tube, one end of the telescopic tube is connected to a fixed baffle, the other end is provided with a movable plate, an exhaust port and an air inlet are provided on the fixed baffle, a cavity is provided under the seat plate, and the cavity A blower is arranged in the cavity, a hose is arranged between the blower and the air inlet, and a sealing structure is arranged outside the exhaust port, and the telescopic tube is inflated by the blower to drive the movable plate to move, so as to realize the patient's hip joint movement. Extruded and fixed, thus achieving the effects of high comfort, convenient operation and simple structure.

Owner:SICHUAN LIZHI JIUCHUANG INTPROP OPERATION CO LTD

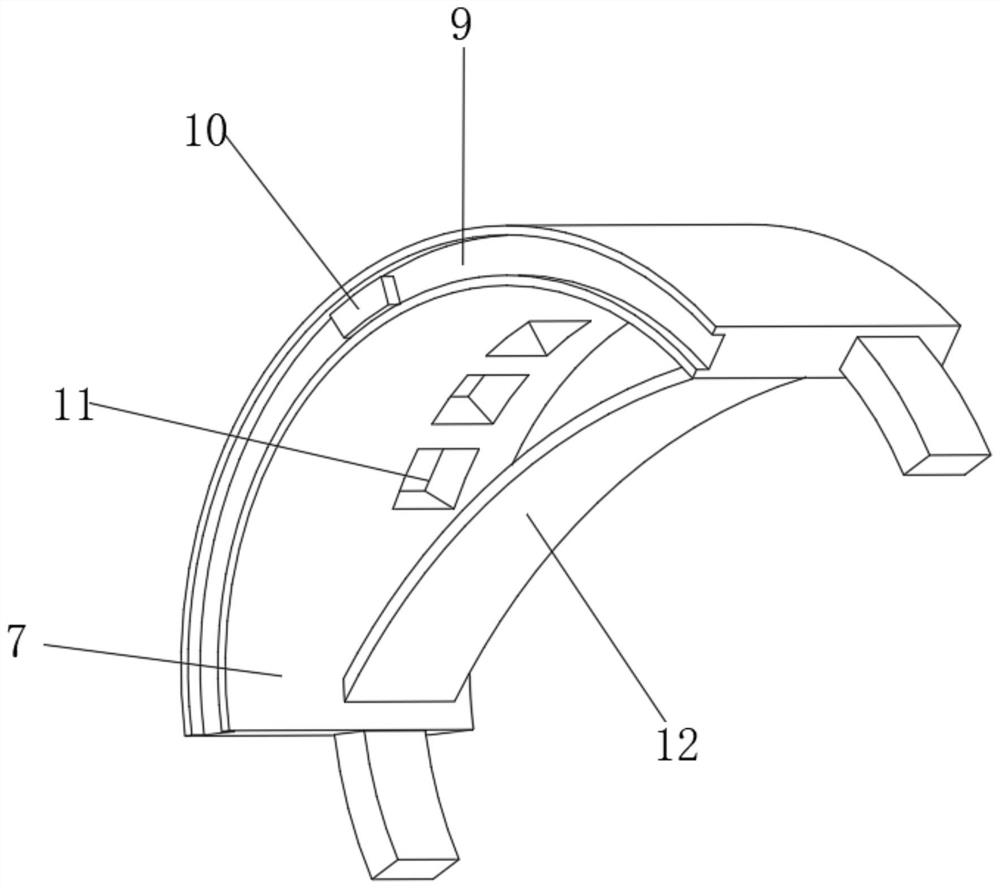

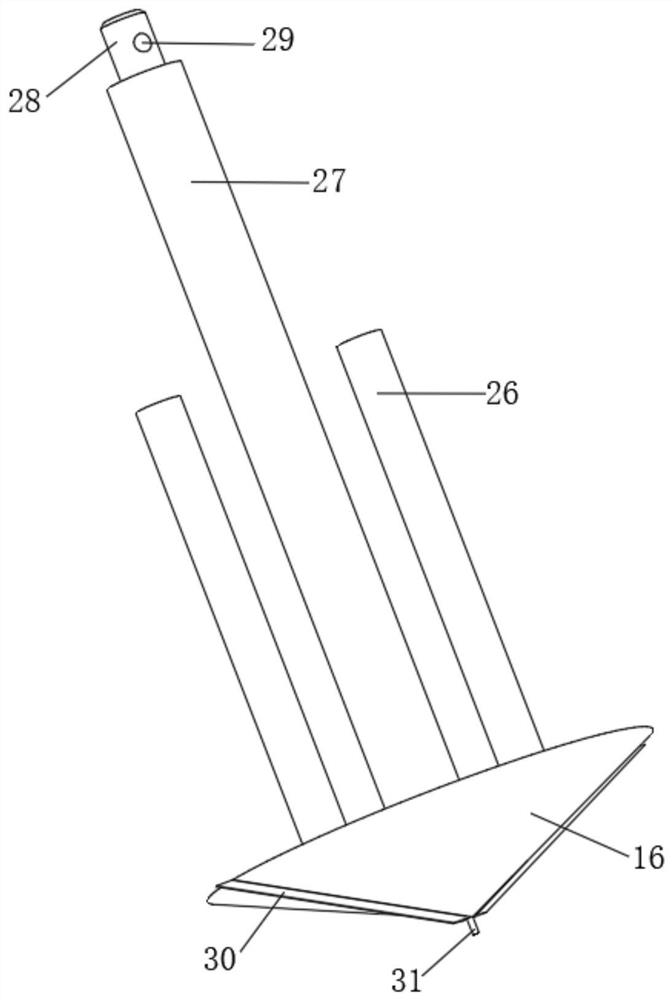

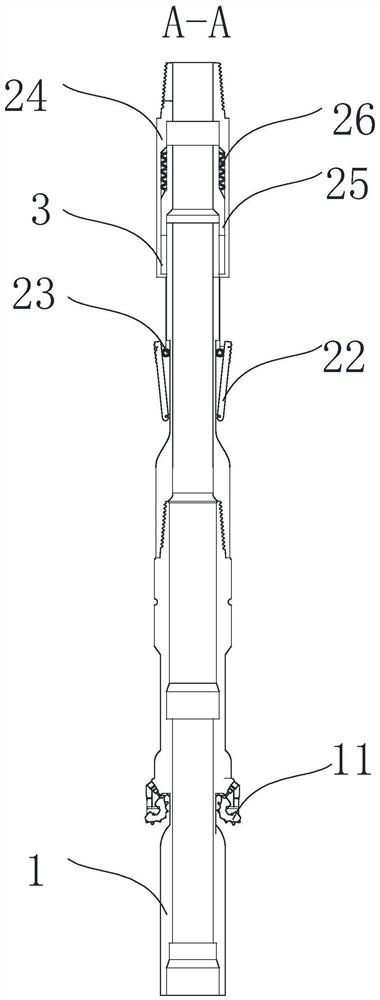

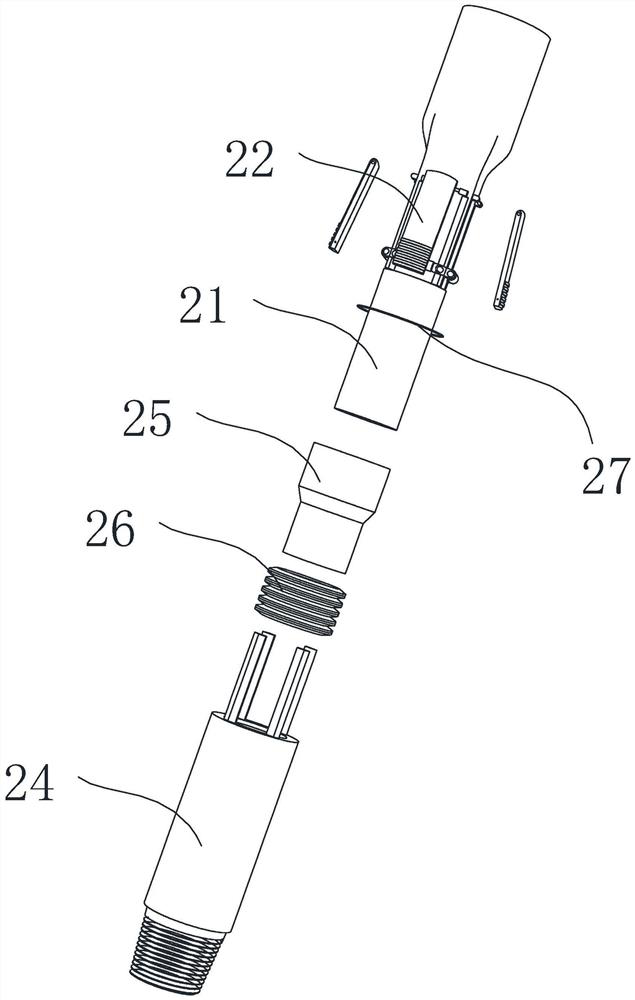

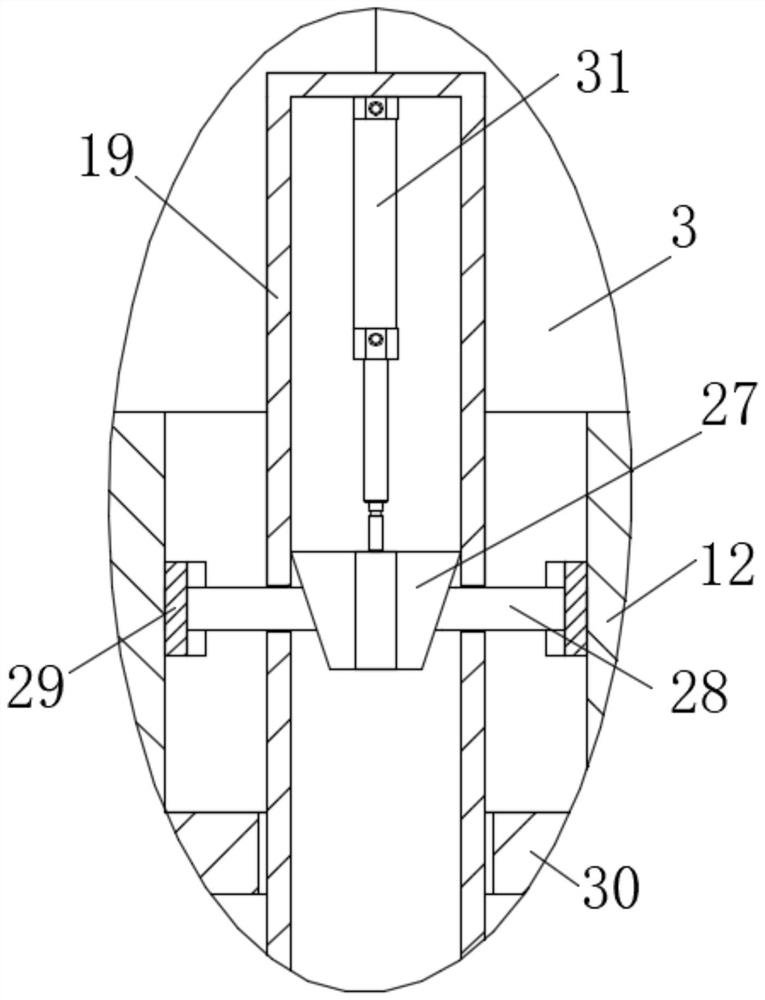

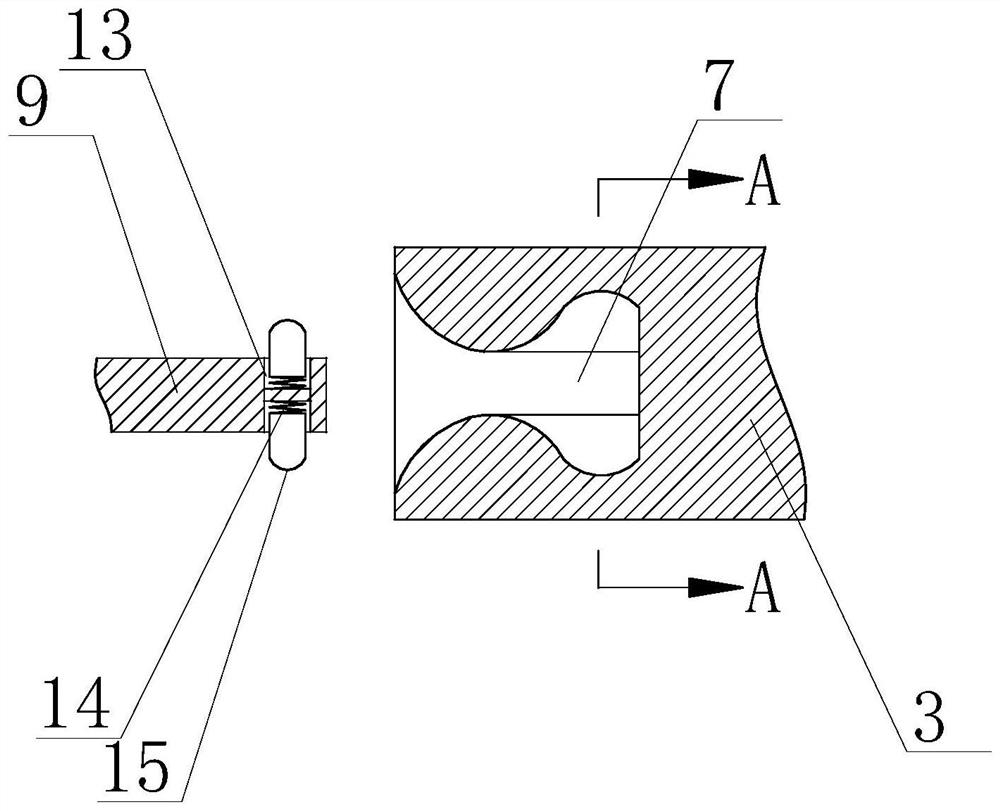

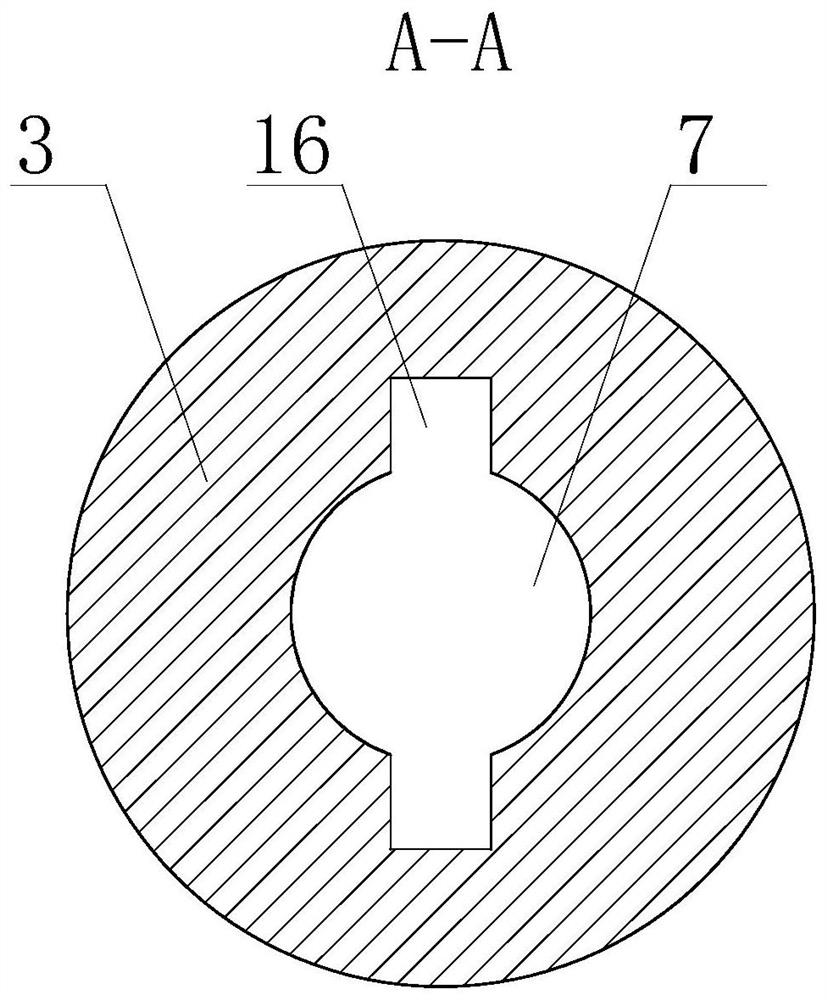

Casing centralizing device and centralizing method for well completion of horizontal well

PendingCN114086897AAffects the expansion angleInfluence angleDrilling rodsDrilling casingsHorizontal wellsReamer

The invention discloses a casing centralizing device and centralizing method for well completion of a horizontal well. The casing centralizing device comprises a reamer and a centralizer which are connected with each other; the reamer is of a cylindrical structure with two open ends, and one end of the reamer is connected with the centralizer; the outer wall of the reamer is rotationally connected with a plurality of cones; the centralizer comprises a centralizer body, a centralizing slip and a sliding mechanism, the centralizing slip is hinged to the outer wall of the centralizer body, and the sliding mechanism can move in the axial direction of the centralizer body to control opening and closing of the centralizing slip. Compared with the prior art, the casing centralizing device has the following advantages that gas in the closed containing cavity is expanded by heating the casing centralizing device for horizontal well completion, the outwards-pushing cylinder drives the hinged centralizing slips to expand towards the periphery, and therefore the centralizer extrudes and fixes the inner wall of a borehole, and by rotating the casing centralizing device for horizontal well completion, the situation that the expansion angle of the centralizing slips towards the periphery is affected by the gravity of the centralizer is avoided, gas is shrunk by reducing the external temperature, then the disc spring pushes the outer pushing cylinder to reset, and the centralizer is made to move.

Owner:CHINA NATIONAL OFFSHORE OIL (CHINA) CO LTD +1

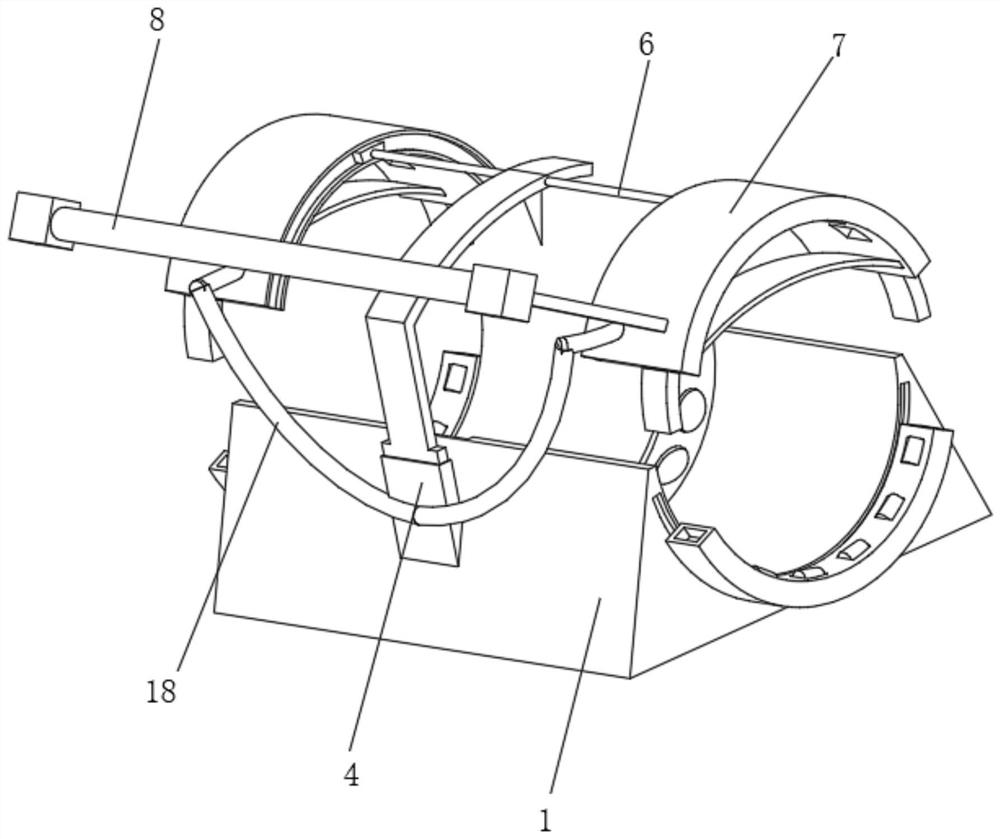

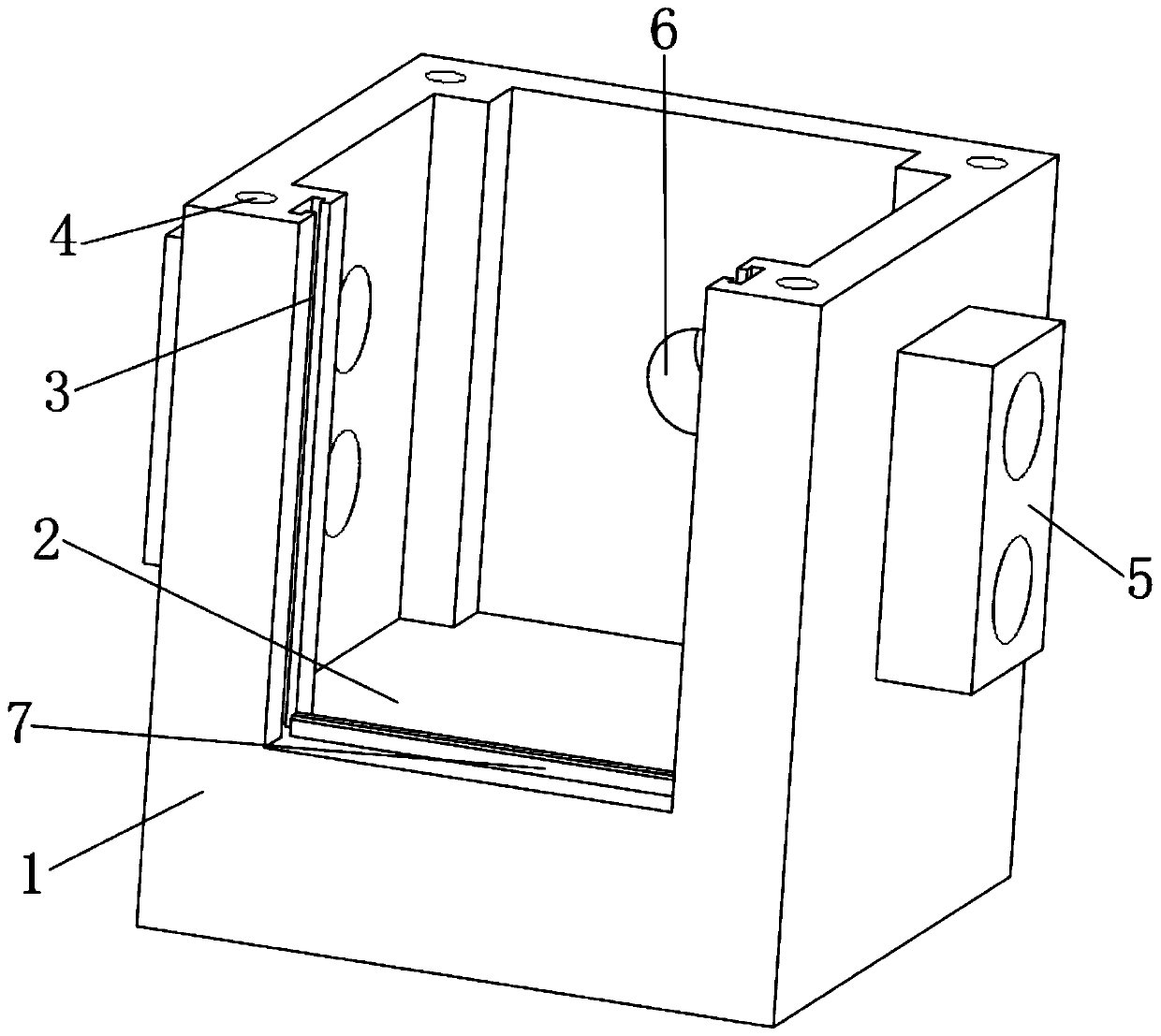

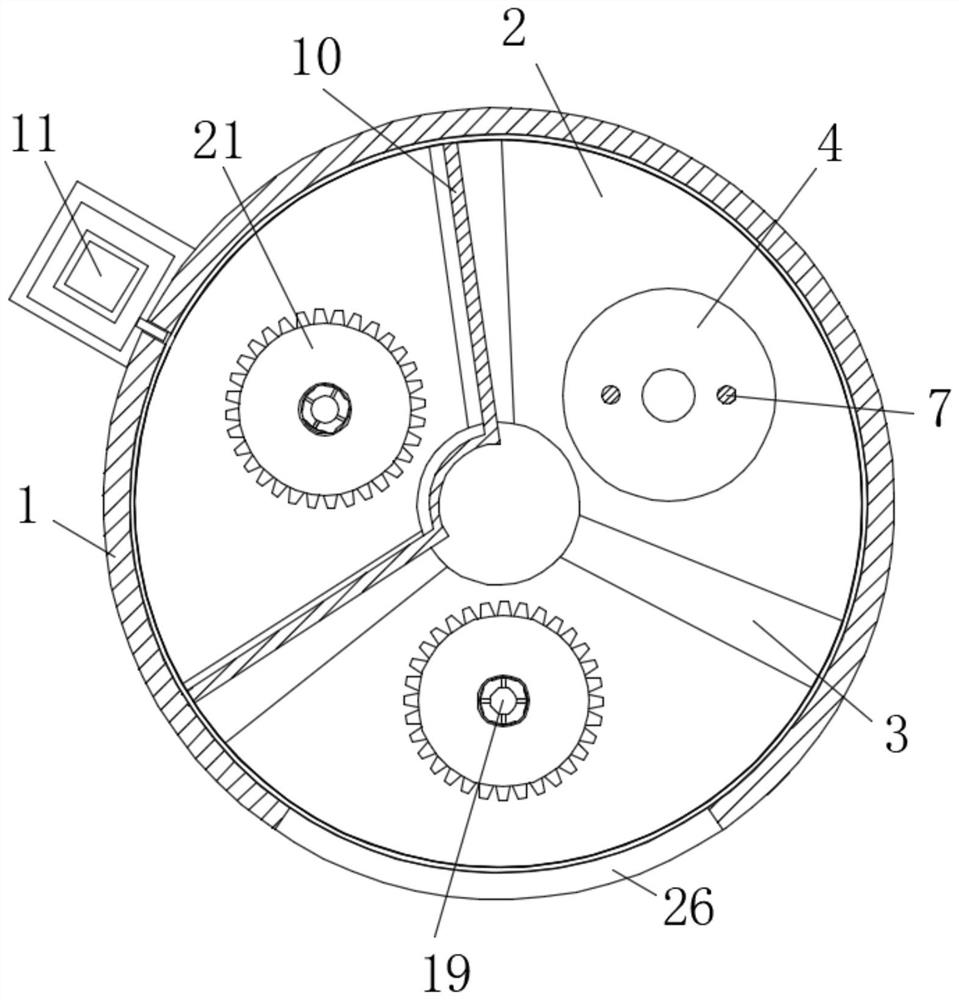

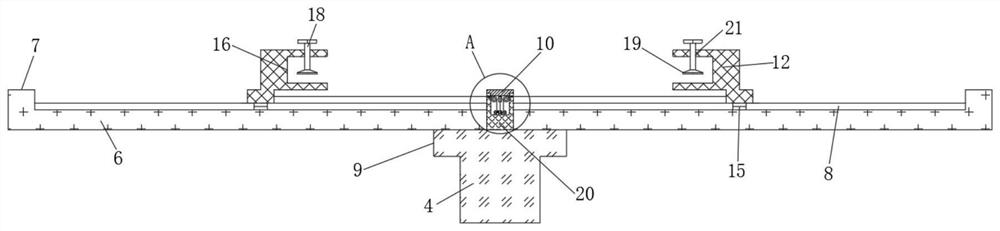

Shot peening strengthening device capable of improving stress distribution on surface of gear

ActiveCN113621772AAchieve squeeze fixationSimple structureCleaning using toolsGear wheelClassical mechanics

The invention belongs to the technical field of gear production and machining, particularly relates to a shot peening strengthening device capable of improving stress distribution on the surface of a gear. Aiming at the problems that existing shot peening strengthening equipment is complex in structure, shots are not uniformly ejected on the gear, workpiece taking and feeding operations are complex, and stains on the surface of the gear cannot be removed, the following scheme is provided, the shot peening strengthening device comprises a box body, a blade disc is rotationally connected to the inner wall of the box body, a power assembly for driving the blade disc to rotate intermittently is arranged on the box body, and three fan-shaped cavities are evenly formed in the blade disc. The shot peening strengthening device is simple in structure, the gear to be strengthened rotates at a constant speed while a shot peening machine works to eject shots, the shots are sprayed to the surface of a to-be-strengthened gear more uniformly and circularly, the strengthening work efficiency is improved through the circulating design, and through an arranged annular hairbrush, surface stain removal can be carried out on the to-be-strengthened gear, and the strengthening effect of device is improved.

Owner:浙江顺天传动科技股份有限公司

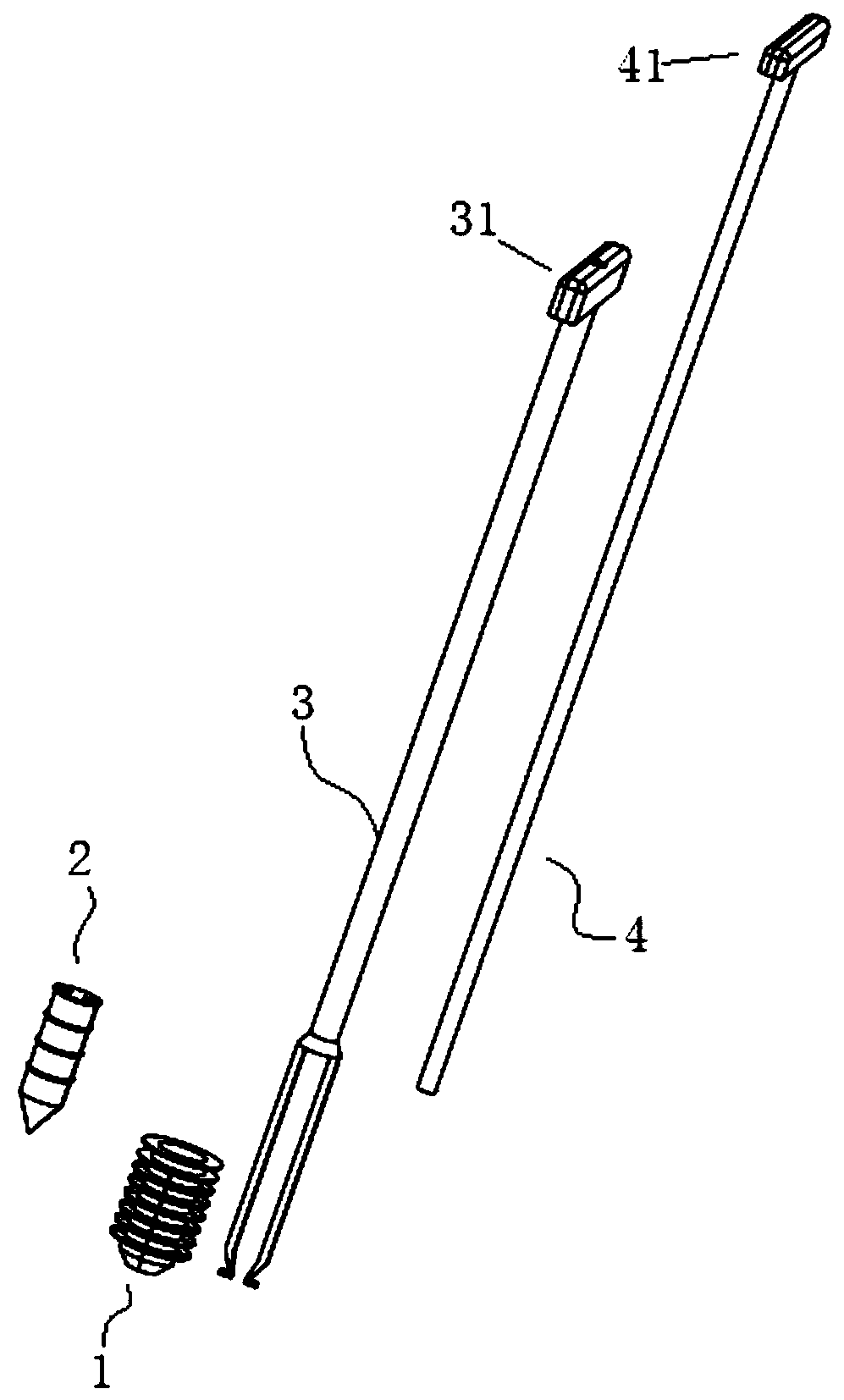

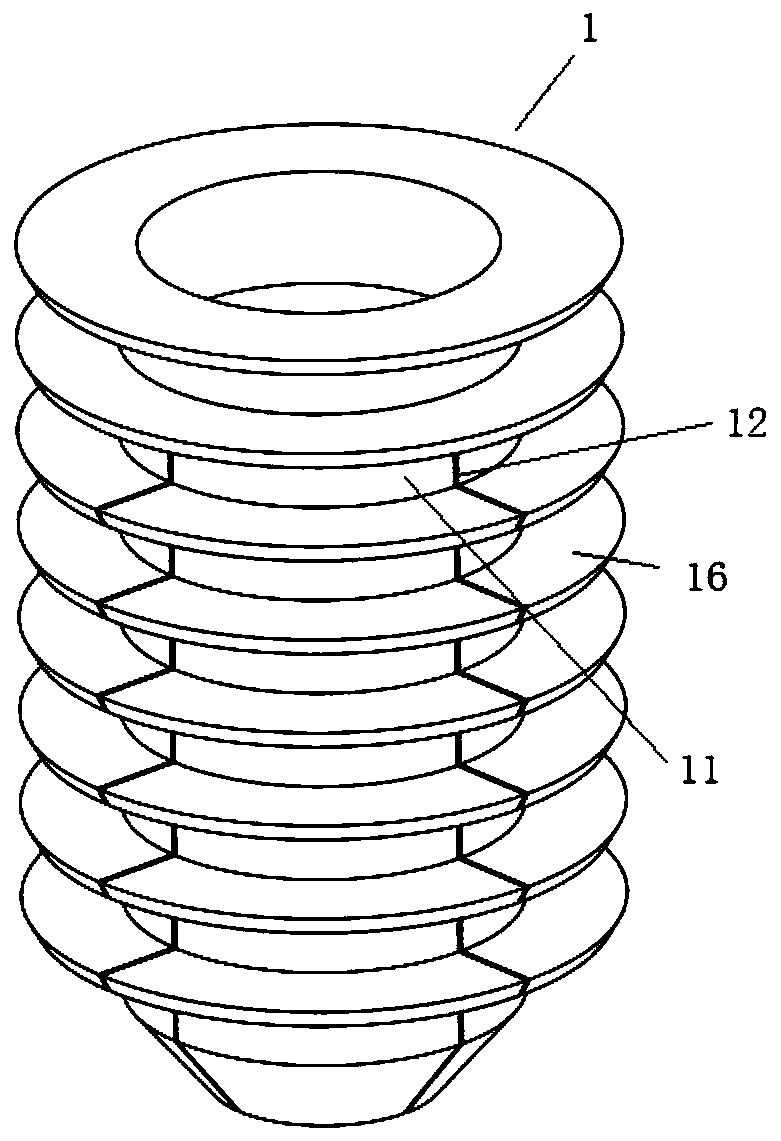

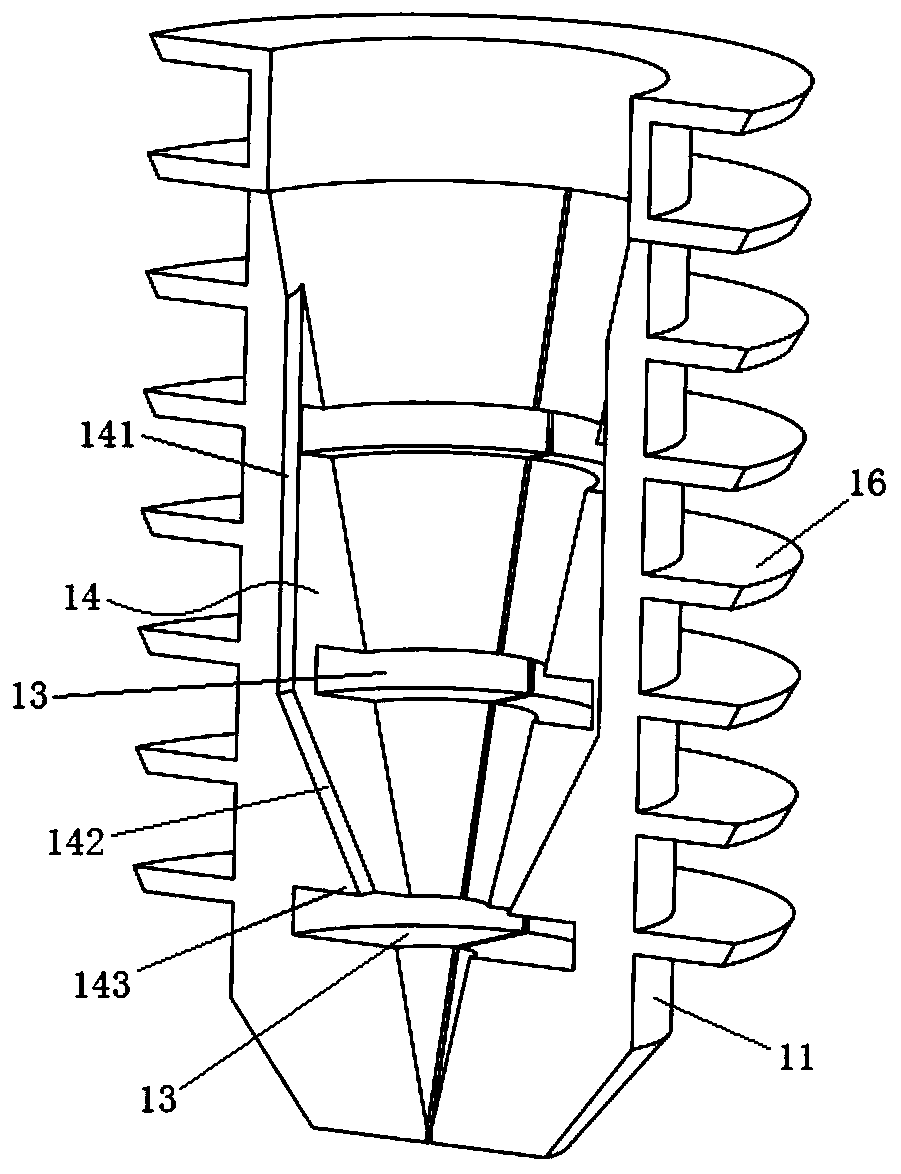

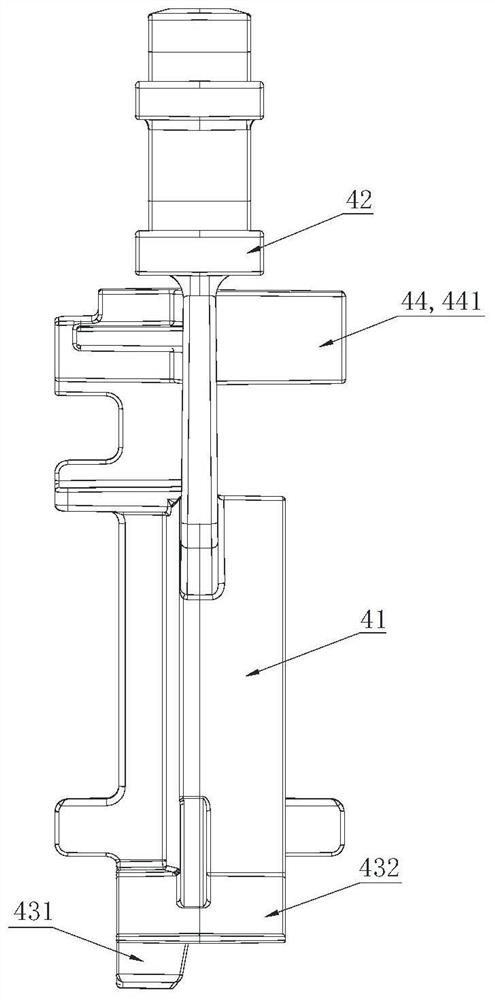

Distal plug

PendingCN111329574AImprove the effect of surgeryEasy to fixJoint implantsFemoral headsMedullary cavityFemoral stem

The present invention provides a distal plug. The distal plug comprises a plug sleeve, a plug shaft, an operation handle and a driving part, wherein the plug sleeve is hollow and can expand outwards after being internally extruded; the plug shaft can be inserted into the plug sleeve, and the plug shaft has an initial position and an extrusion position inside the plug sleeve; in the initial position, the plug sleeve does not expand outwards; in the extrusion position, the plug sleeve expands outwards under the extrusion action of the plug shaft; the operation handle can be detachably connectedwith the plug sleeve inserted into the plug shaft, and can convey the plug sleeve inserted into the plug shaft to a target position; and the driving part is used for applying external force to the plug shaft to drive the plug shaft to move from the initial position to the extrusion position and then is separated from the plug shaft. The distal plug can pass through the isthmus and can be firmly fixed inside the medullary cavity to form a reliable barrier, so that bone cement is conveniently pressurized, sufficient micro-interlocking is formed between the bone cement and the cancellous bone ofthe femur, the femoral stem is firmly fixed, and the surgical effect can be improved.

Owner:山东大学齐鲁医院(青岛)

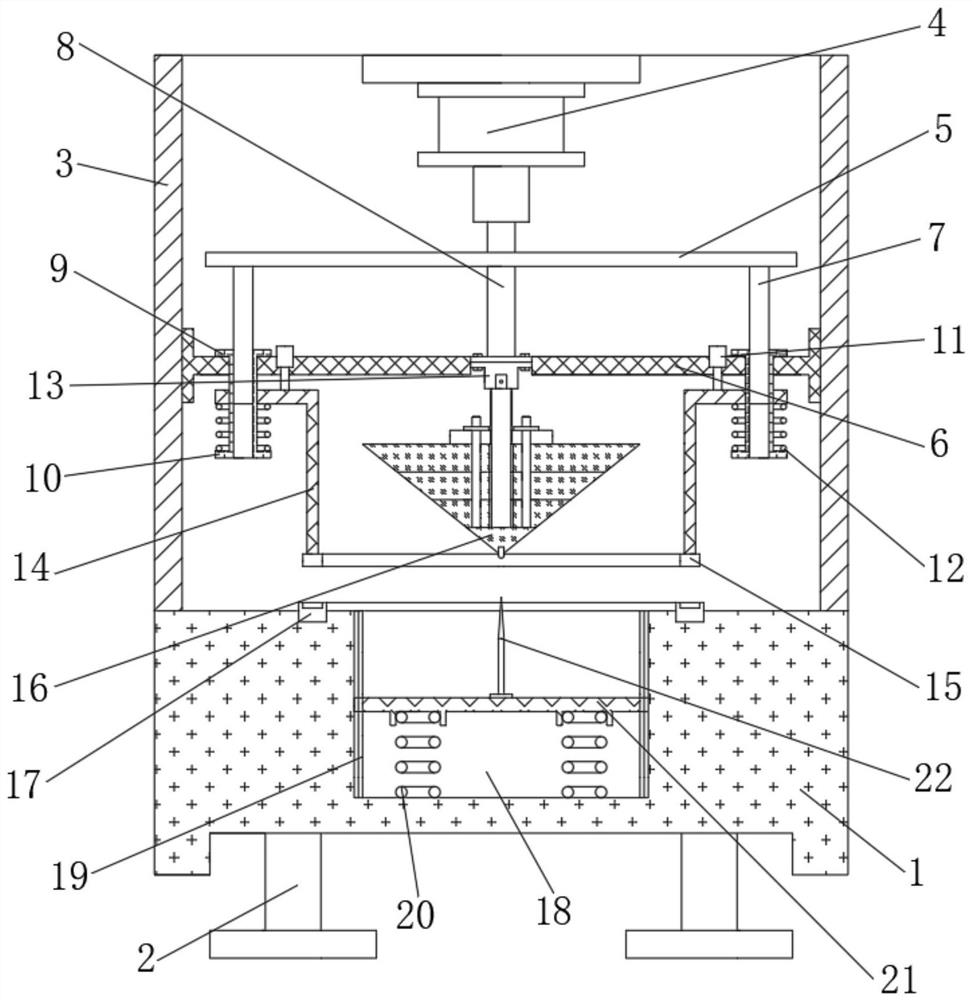

Grooving equipment for mold production

InactiveCN112296447ARealize the effect of pressing the upper part of the fixed dieAchieve the effect of fixing the upper part of the moldPositioning apparatusMetal-working holdersMechanical engineeringIndustrial engineering

Owner:刘传福

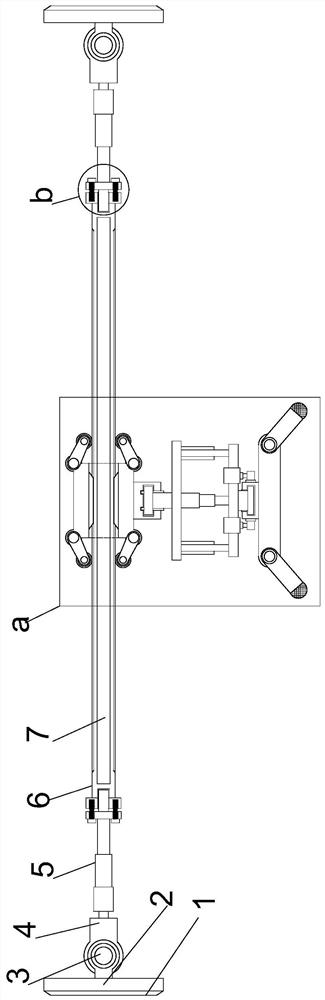

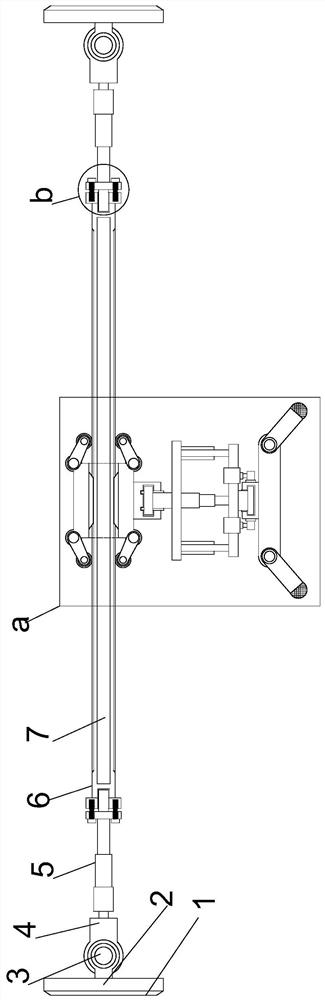

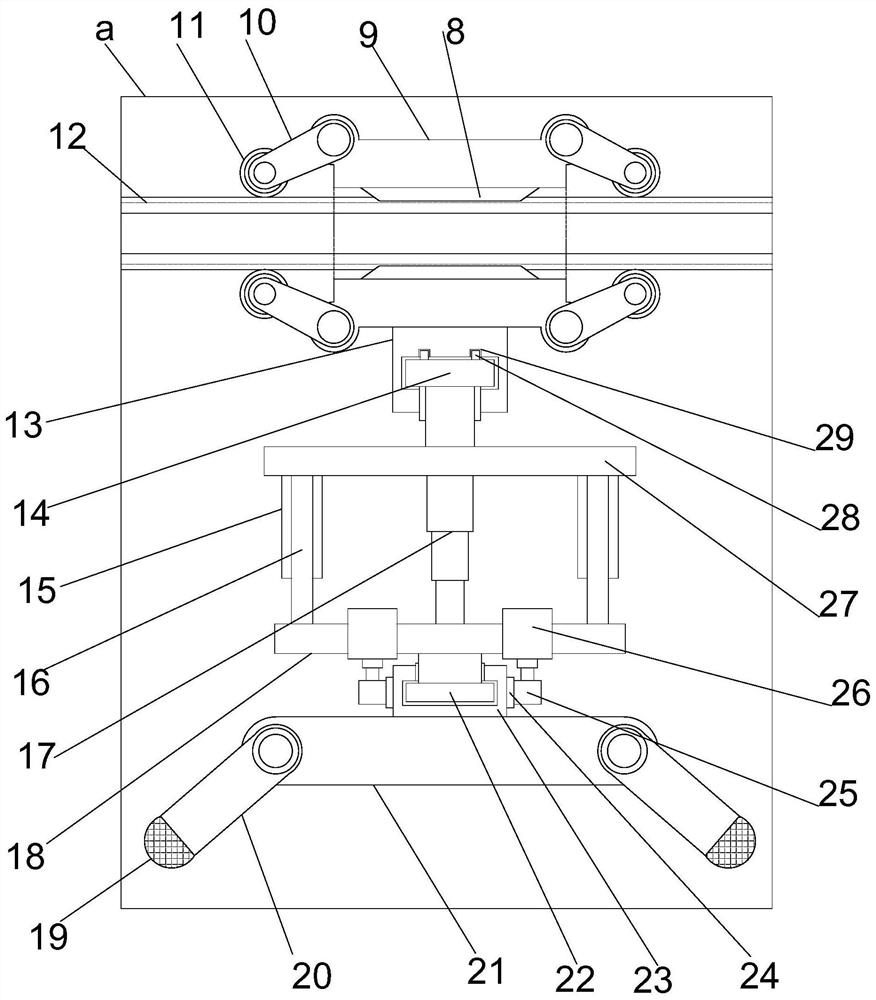

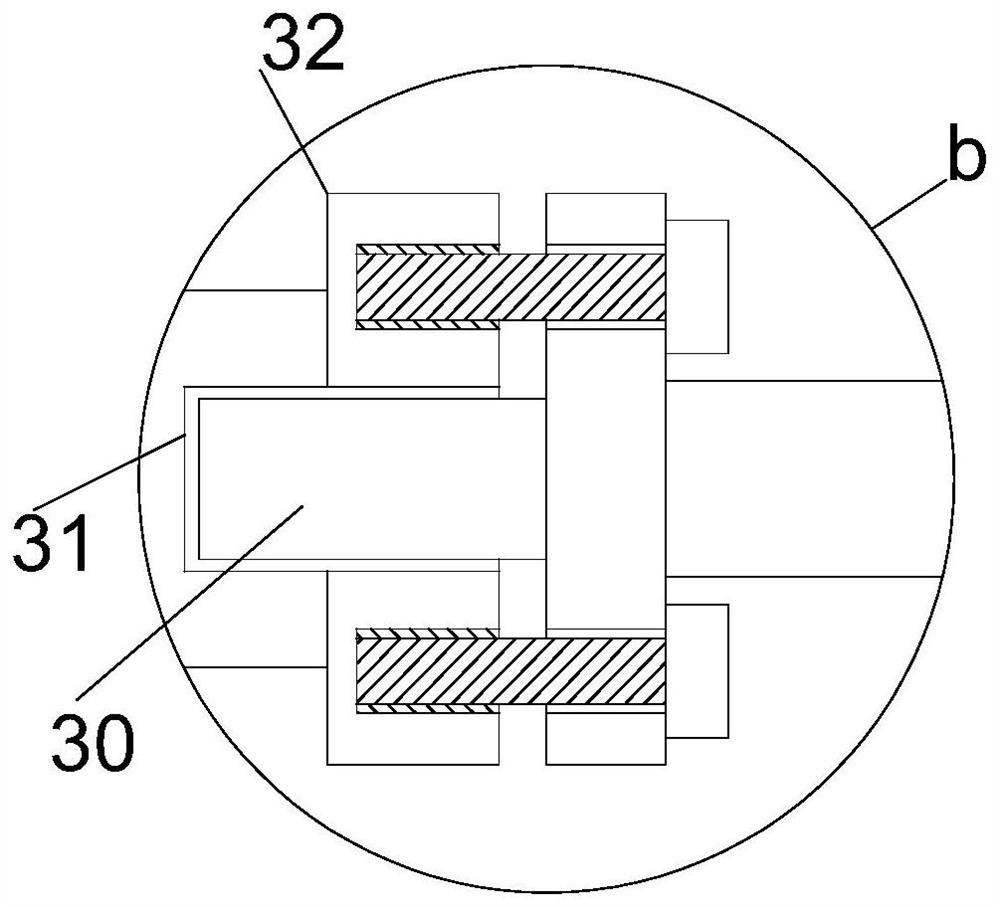

Portable type state monitoring device for numerical-control machine tool

ActiveCN113263357AEfficient acquisitionEasy to transportMeasurement/indication equipmentsNumerical controlControl engineering

The invention relates to the field of numerical-control machine tool monitoring, in particular to a portable type state monitoring device for a numerical-control machine tool. The portable type state monitoring device comprises a supporting mounting column and further comprises two groups of rotary telescopic fixing modules and a movable displacement monitoring module, wherein the two groups of rotary telescopic fixing modules are respectively arranged at the two ends of the supporting mounting column, and are connected with the supporting mounting column through positioning mounting structures; the movable displacement monitoring module is movably mounted on the supporting mounting column. Through a combined type positioning mounting structure, the device is convenient to transport and load; through telescopic steering adjustment, extruding and fixing of the device is achieved, so that the device can be suitable for mounting numerical-control machine tools with different internal structures; and the portable type state monitoring device can perform initial angle adjustment; multi-shaft rotation adjustment is matched with height adjustment, so that multi-angle monitoring operation is realized; and moreover, displacement under guide moving effect is realized, so that the monitoring range is further expanded, and thus, the device can efficiently obtain the state of the numerical-control machine tool.

Owner:吉林大学重庆研究院

An auxiliary writing device and method for chalk blackboard writing on a vertical surface

ActiveCN111688388BEasy to operateEasy to useWriting connectorsWriting aidsDisplay boardStructural engineering

The invention discloses an auxiliary writing device for chalk and blackboard writing on a vertical surface and a method thereof, belonging to the field of teaching. An auxiliary writing device for writing on a chalk blackboard on a vertical surface and a method thereof, comprising a display board, a rolling bearing, a movable shaft and an annular sleeve, the outer wall of the display board is connected with a vertical column, the outer wall of the vertical column is connected with a connecting plate, and the vertical column and the connecting plate are connected with each other. There is a welding connection between the connecting plates, a fixing rod runs through the inner side of the connecting plate, and the end of the fixing rod is provided with a connecting plate, the side of the connecting plate is provided with a strip plate, and the connecting plate and the strip plate are The inner side of the strip plate is provided with a sliding rail, the inner side of the sliding rail is provided with a sliding block, and the top of the sliding block is provided with a casing, and the sliding block and the casing are welded together. The inner side of the body is provided with a spring, and the end of the spring is connected with an extrusion block; the invention facilitates the need to rotate and exchange the end of the chalk, and facilitates the storage and movement of the writing device.

Owner:南京掌学在线信息科技有限公司

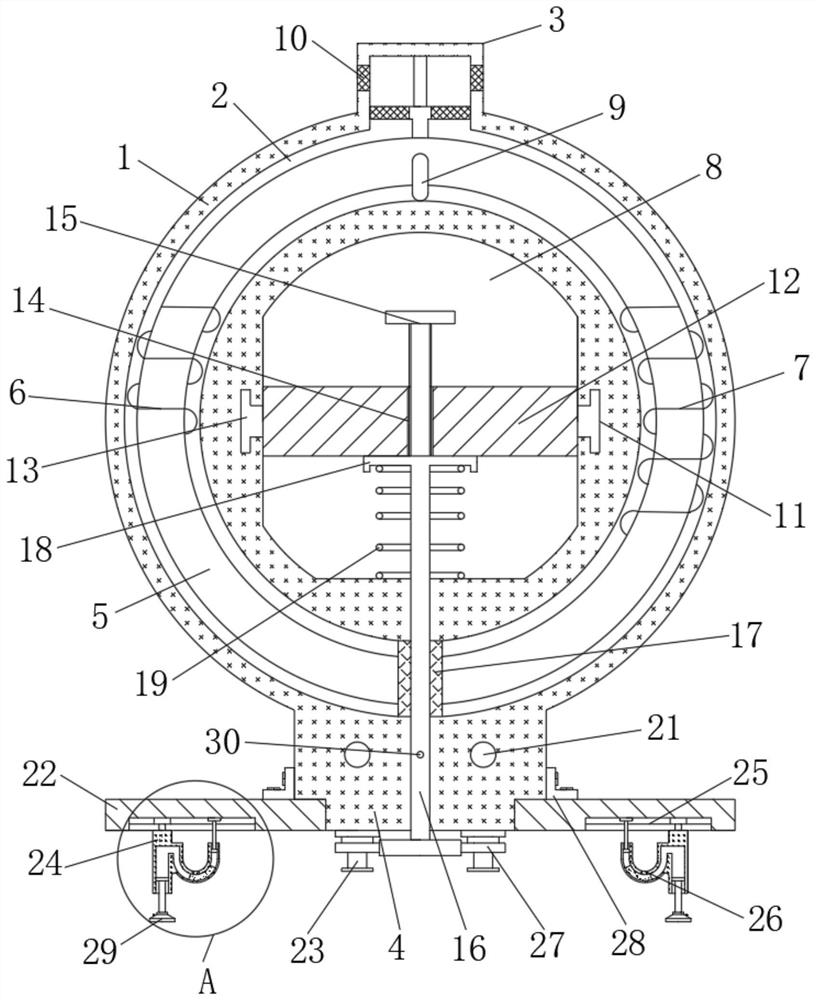

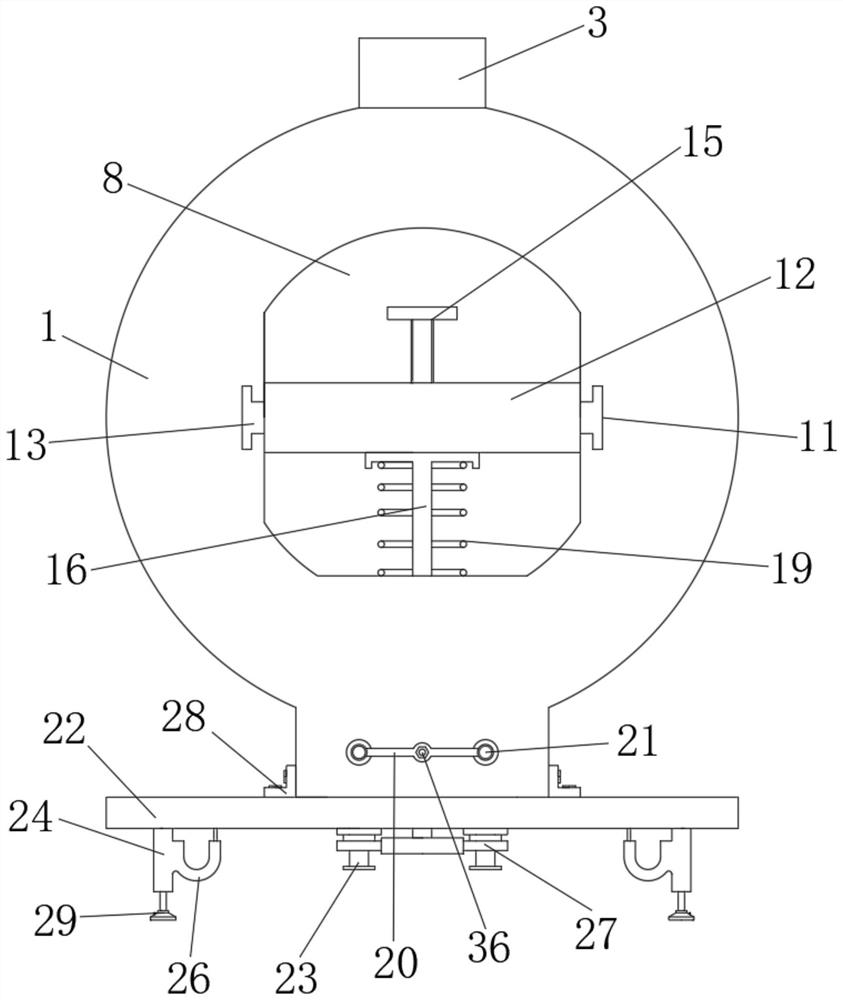

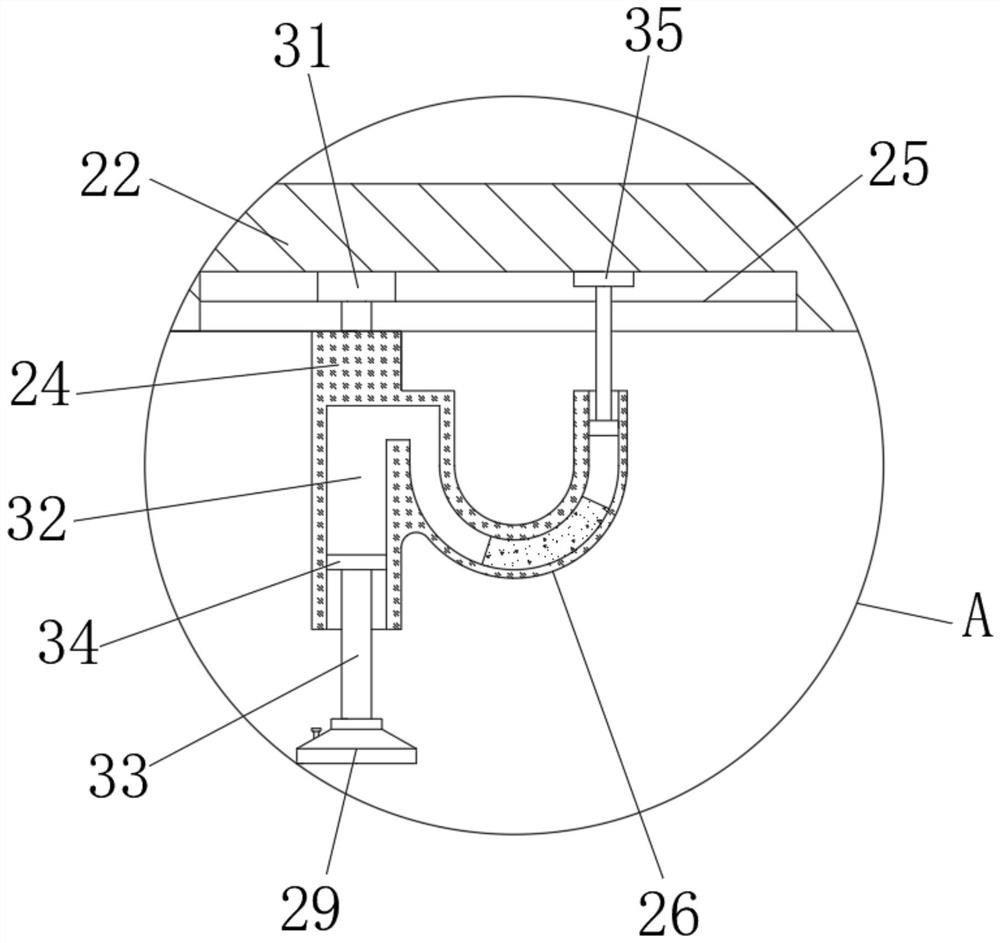

Mutual inductor with stable fixing structure

ActiveCN112908621AImprove the installation rangeImprove installation stabilityTransformers/reacts mounting/support/suspensionTransformers/inductances coolingHemt circuitsInductor

The invention relates to the technical field of mutual inductor installation, in particular to a mutual inductor with a stable fixing structure. The mutual inductor comprises a mutual inductor shell, a circular ring inner cavity of the mutual inductor shell is set as an installation inner cavity, a heat dissipation boss is arranged in the middle of the upper end of the mutual inductor shell, and a plugging base is arranged at the lower end of the mutual inductor shell. The mutual inductor has the beneficial effects that by arranging the sliding mounting block, the left and right mounting and fixing positions are matched with the interval between the adjacent circuits, the mounting and fixing range of the mutual inductor is widened, the mounting stability of the mutual inductor is greatly enhanced, and meanwhile, the pressing change of a U-shaped pipe is utilized to realize extrusion and fixation of the sliding position; through the cooperation of the pull rod and the plugging frame, the connection position of the binding post is pressed and fixed, so that the stability of circuit connection is improved, through the cooperation of the extrusion screw rod and the locking nut, the wiring position is conveniently disassembled, and the installation efficiency of the mutual inductor is greatly improved.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER COMPANY TAIZHOU POWER SUPPLY

A device for preventing damage and perforation of protective clothing

ActiveCN112518879BEasy to replaceEasy to adjustSevering textilesMetal working apparatusStructural engineeringMechanical engineering

The invention relates to the technical field of protective clothing processing, in particular to an anti-damage perforating device for protective clothing, comprising a perforating processing table, a concave perforating inner cavity is opened downward in the middle of the upper end surface of the perforating processing table, and a bearing is arranged on the upper end of the perforating processing table. Pressure ring, the left and right sides of the upper end surface of the perforation processing table are symmetrically welded with side plates vertically, the beneficial effect is: the present invention realizes the extrusion of the textile thread around the perforation position of the protective clothing through the cooperation of the pressure ring and the pressure bearing ring Fixed, so as to reduce the stretching of the thread during the punching process, reduce the stretching force between the threads, reduce the degree of deformation of the thread after breaking, and greatly improve the quality of the perforation; by setting the positioning pin, the precise position of the perforation can be realized Positioning, at the same time, using the positioning pin on the protective clothing to realize the opening of the perforation position, which greatly facilitates the subsequent reaming and cutting, which not only improves the position accuracy of the perforation, but also increases the convenience of perforation cutting, reducing The squeeze force is reduced.

Owner:潍坊坤泽尔安全防护用品有限公司

An outlet panel arrangement device for a power distribution cabinet

ActiveCN111244766BBeautiful distributionNeatly distributedBus-bar/wiring layoutsEngineeringControl theory

The invention relates to the technical field of power distribution cabinets, in particular to an outlet panel arrangement device for a power distribution cabinet, including a power distribution cabinet, the middle cavity of the power distribution cabinet is set as an installation cavity, and the left and right sides of the front opening of the power distribution cabinet The side outer wall is provided with a pair of mutually symmetrical slots, the upper end surface of the power distribution cabinet is provided with a sealing cover plate, and an input jack is opened in the middle of the rear end surface of the power distribution cabinet. The output position is fixed by using the wiring board, so as to achieve the purpose of wiring, making the distribution of cables in the power distribution cabinet more beautiful and tidy, which is convenient for circuit analysis and maintenance; by setting the sliding column with spring extrusion and semicircle The cooperation of the clamping block realizes the extrusion and fixing of the output cable. By changing the model of the clamping block, it is suitable for cables of different thicknesses and specifications, so that the position of the cable arrangement is further fixed to avoid falling off.

Owner:CHANGSHU GENERAL ELECTRIC APPLIANCE FACTORY

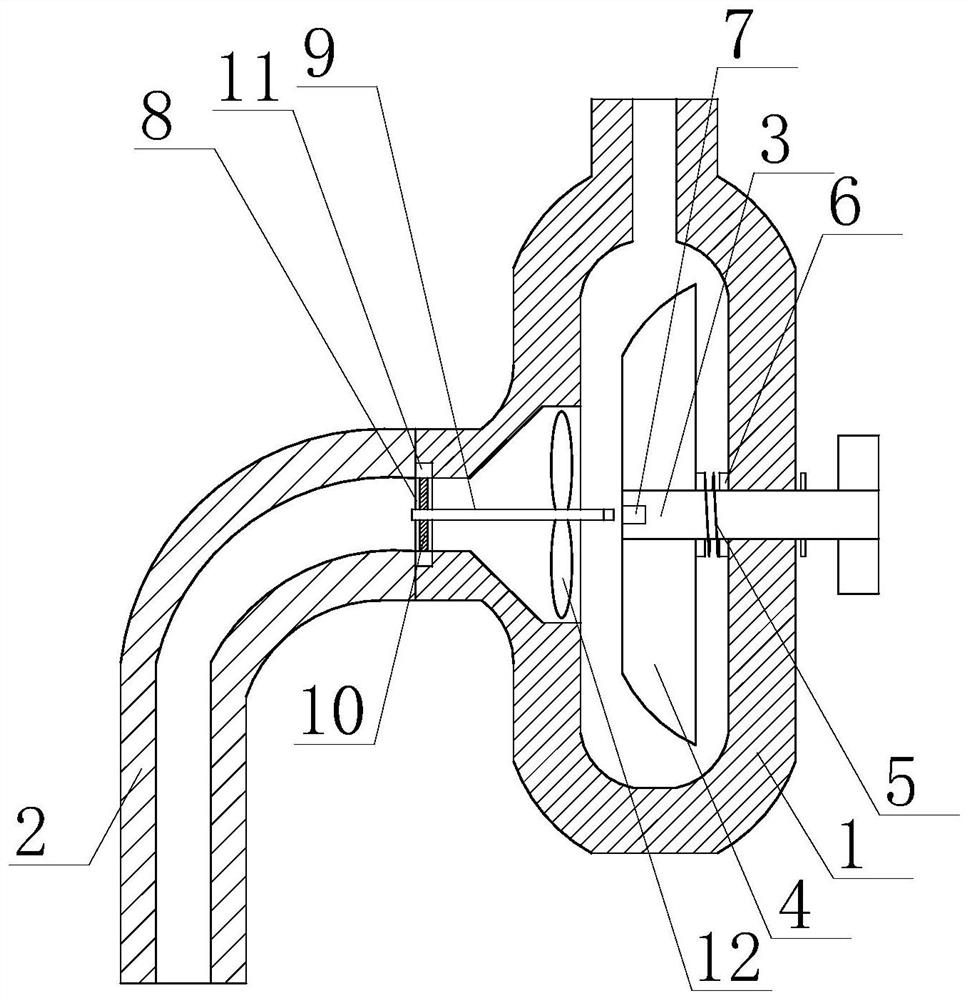

A kind of automatic liquid filling centrifugal pump

ActiveCN109488609BSimple processReduce laborPump componentsPriming pumpDrive shaftElectric machinery

The invention belongs to the field of centrifugal pumps and particularly relates to an automatic liquid filling centrifugal pump. A pump body is included, and the left side wall of the pump body communicates with a water pumping pipe; a driving shaft is arranged on the right side wall of the pump body in a penetrating manner, and the portion, located in the pump body, of the driving shaft is sleeved with an impeller; the driving shaft can be made to rotate in a manner that belt transmission is adopted for the driving shaft or in a manner that the driving shaft is directly fixedly connected with an output shaft of a motor, and then the impeller is driven; due to the effect of the centrifugal force, liquid is pumped in from the water pumping pipe and then is conveyed out for filling; and thedriving shaft is sleeved with an adjusting spring. According to the automatic liquid filling centrifugal pump, by adding fan blades, a driven shaft and the adjusting spring, when the pump body just starts to work, the driving shaft and the driven shaft can be fixed, the fan blades are driven to rotate, the pump body is fast filled with the liquid due to the negative pressure generated by the fanblades, work procedures are simplified, and the labor amount is reduced.

Owner:安徽凯特泵业有限公司

A Hydraulic Casing Centralizer Used in Oil Exploitation

ActiveCN112096310BFastenAchieve extrusionDrilling rodsDrilling casingsStructural engineeringMechanical engineering

The invention discloses a hydraulic casing centralizer for petroleum exploitation, which belongs to the technical field of petroleum completion engineering and comprises a casing, a wellbore fastening expander and a double linkage centralizing mechanism. The casing is tightened along the wellbore The vertical axis of the solid expander is inserted into the wellbore fastening expander. The two ends of the casing and the wellbore fastening expander are respectively provided with double-linkage centralizing mechanisms. The two double-linkage centralizing mechanisms are vertically The direction is symmetrical with respect to the center line of the horizontal direction of the borehole fastening expander. The casing is fixed in the wellbore and the position of the casing is realized through the borehole fastening expander, and the flexible centralization of the casing is realized through the double linkage centralization mechanism. Fixing, that is, the double-linkage righting mechanism in the present invention realizes the flexible righting and fixing of the casing through the combination of air pressure and hydraulic pressure, so that the casing has strong plasticity and quick response during use, and it is safe for casing and other oil well construction equipment. Play a certain degree of flexible protection.

Owner:胜利油田固邦石油装备有限责任公司

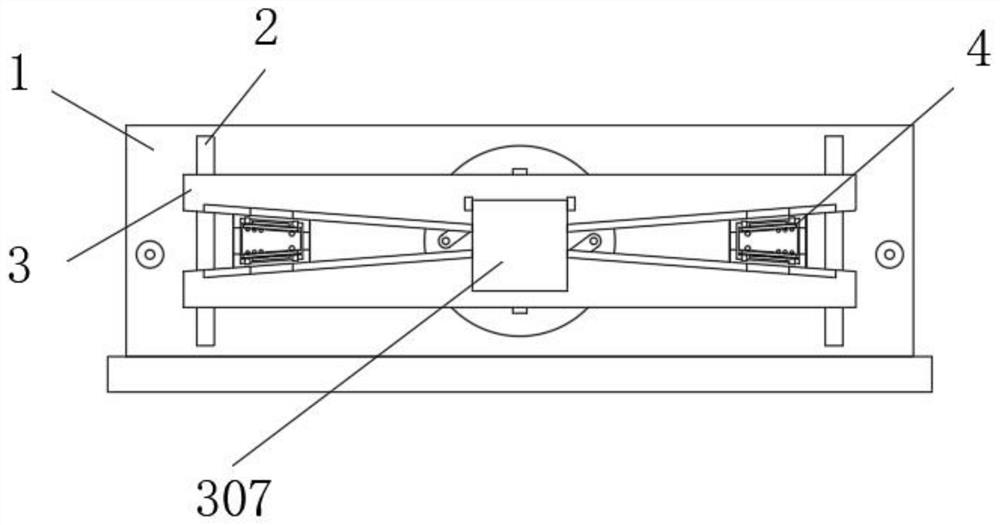

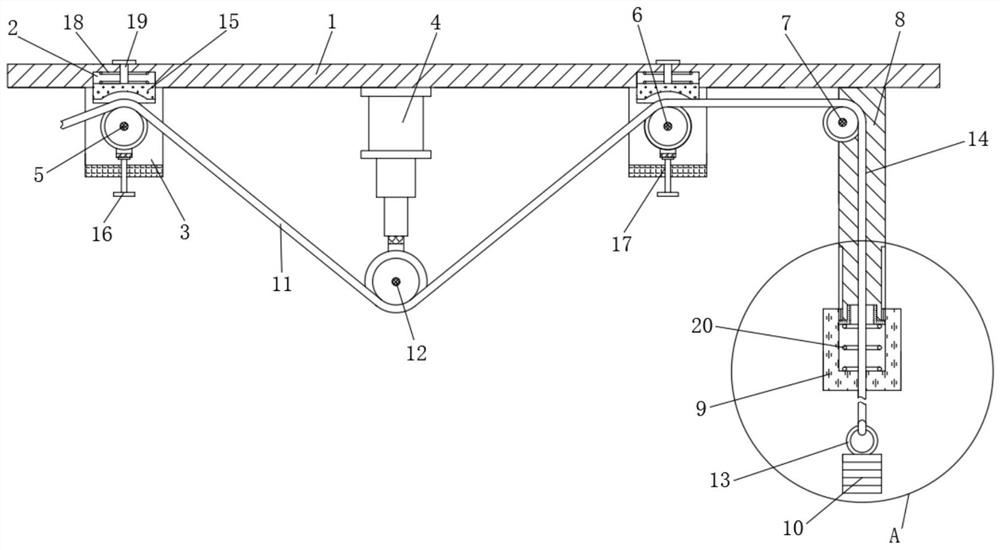

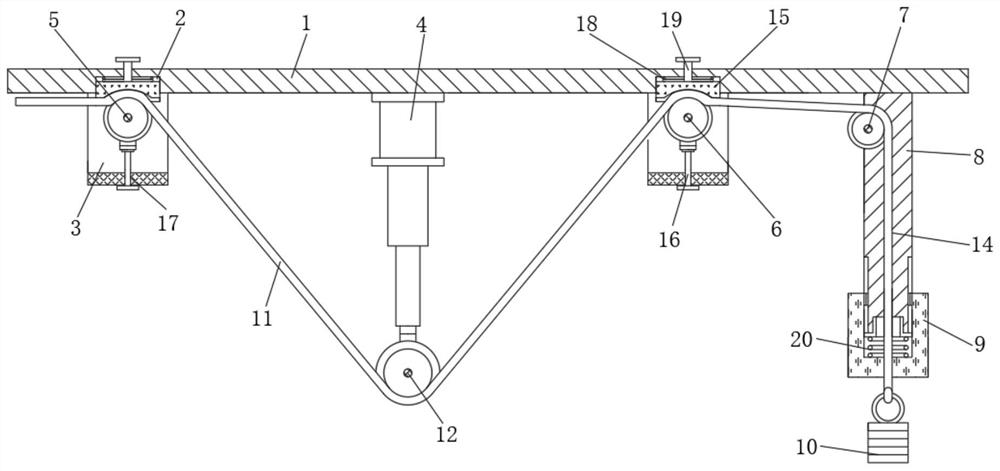

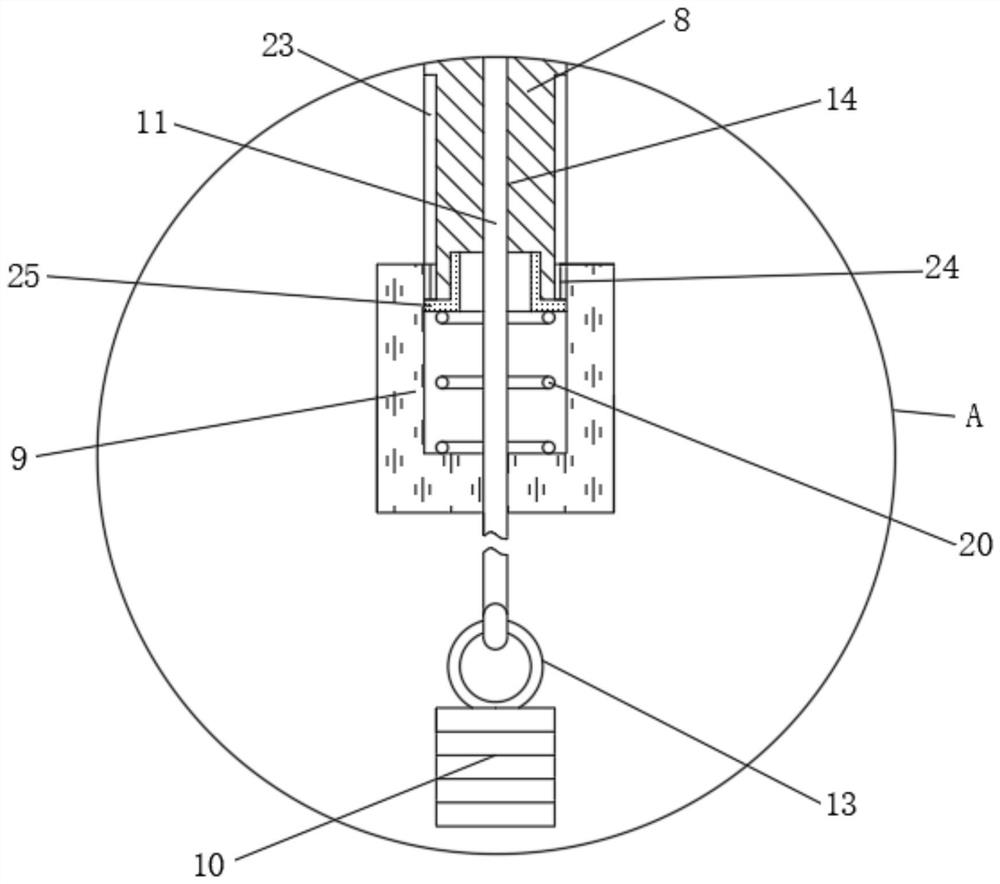

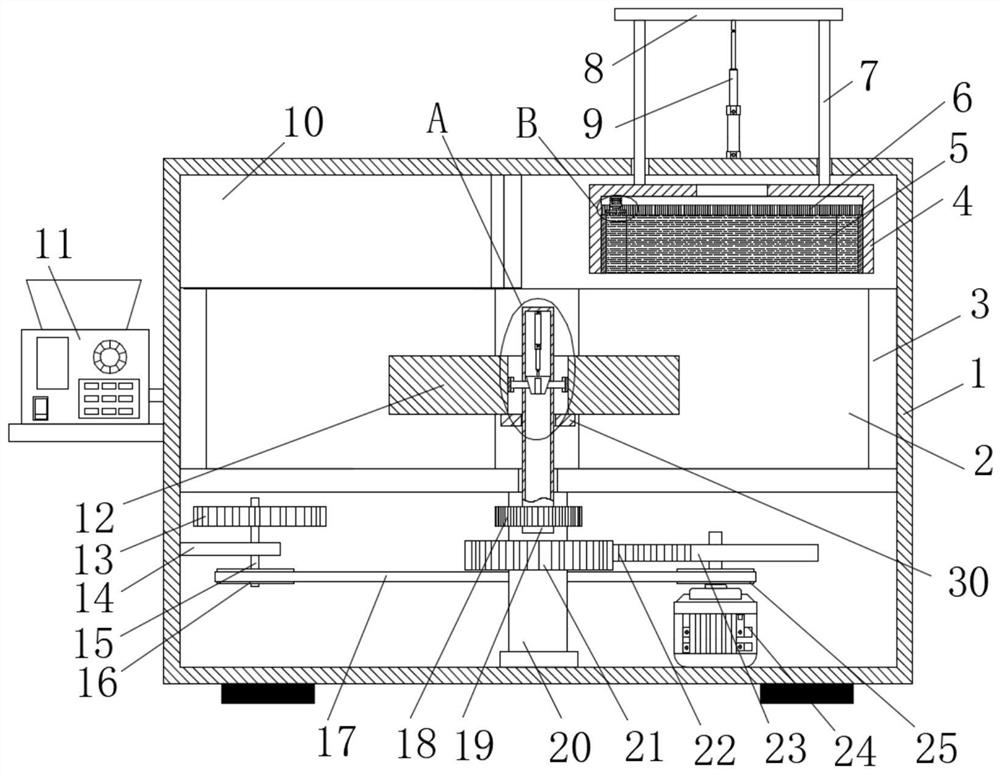

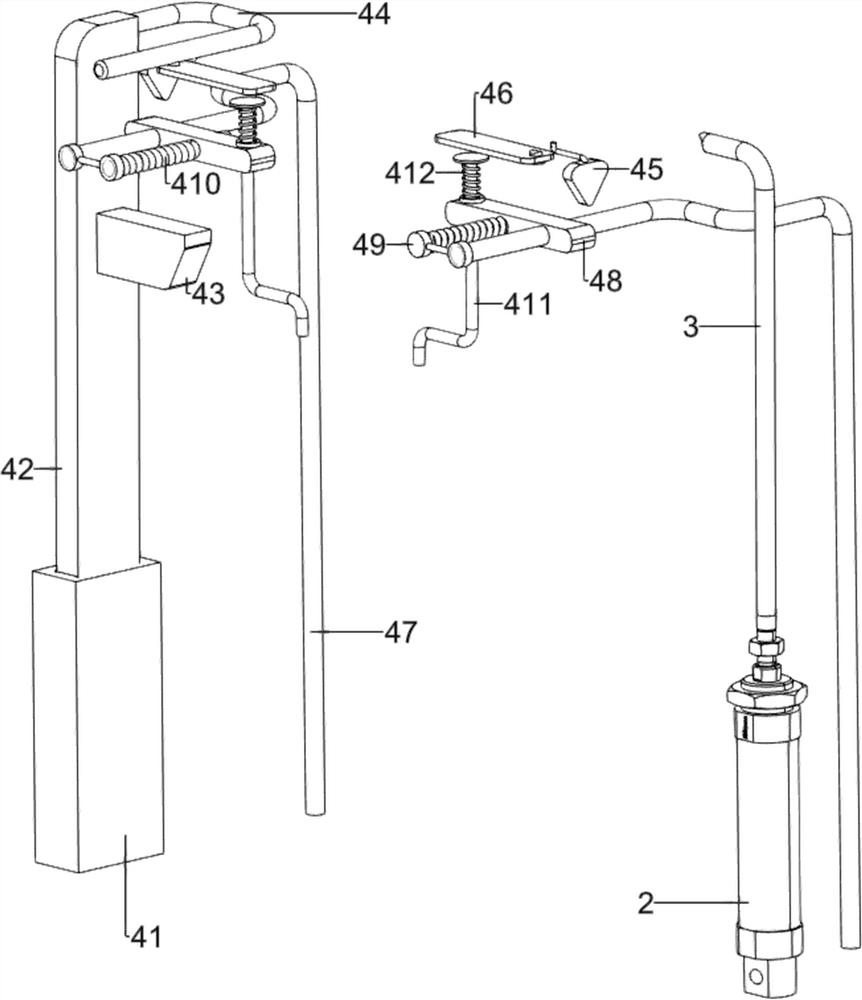

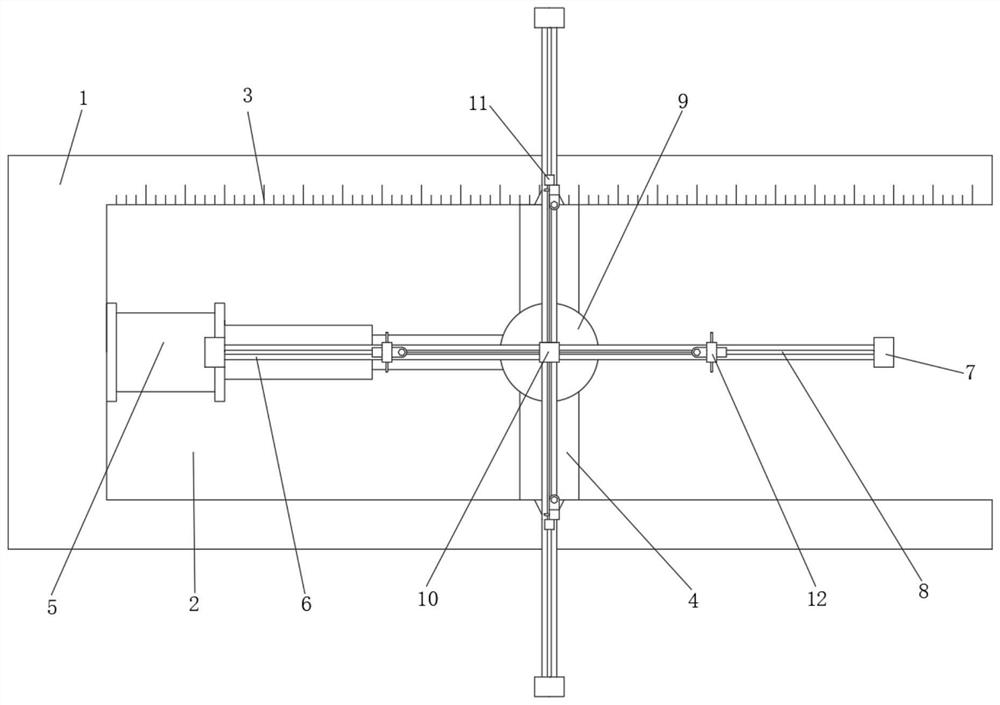

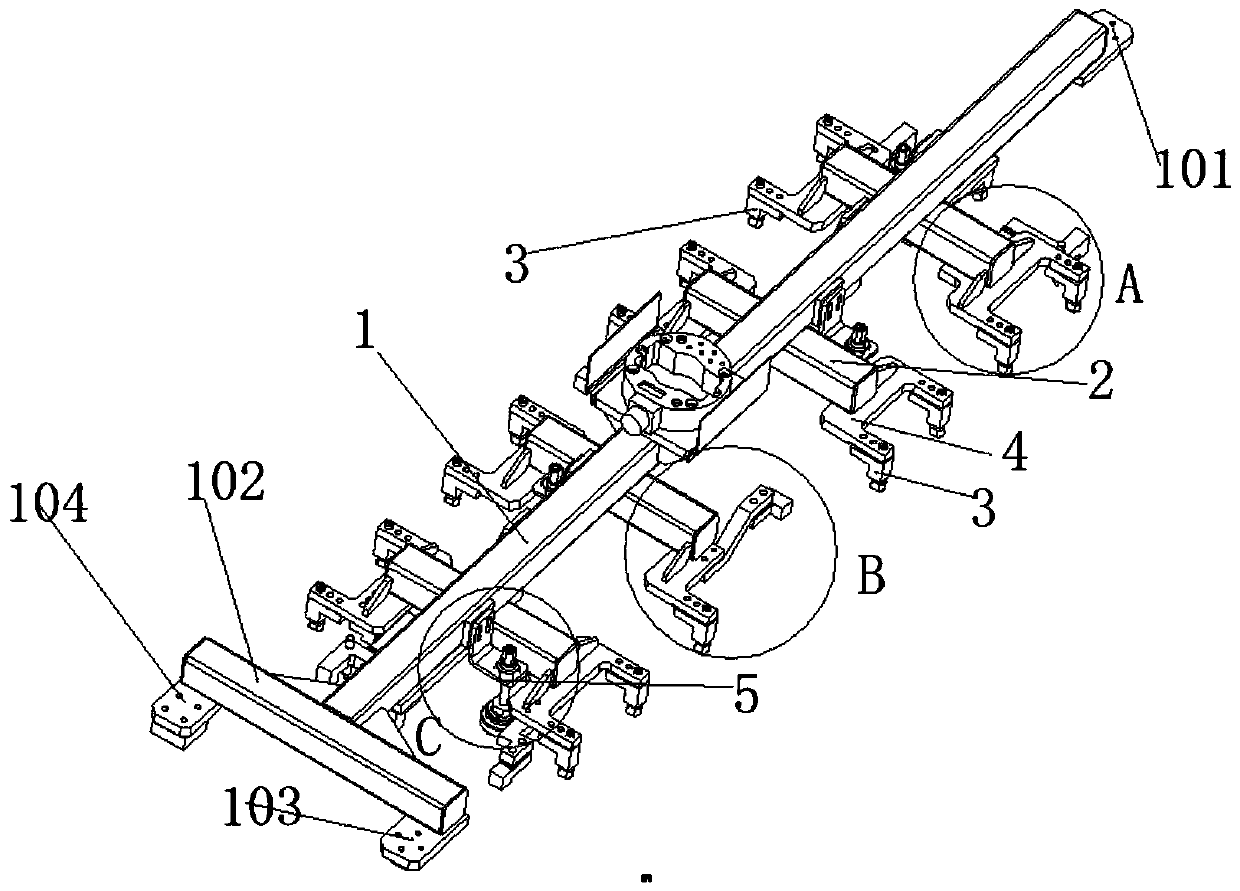

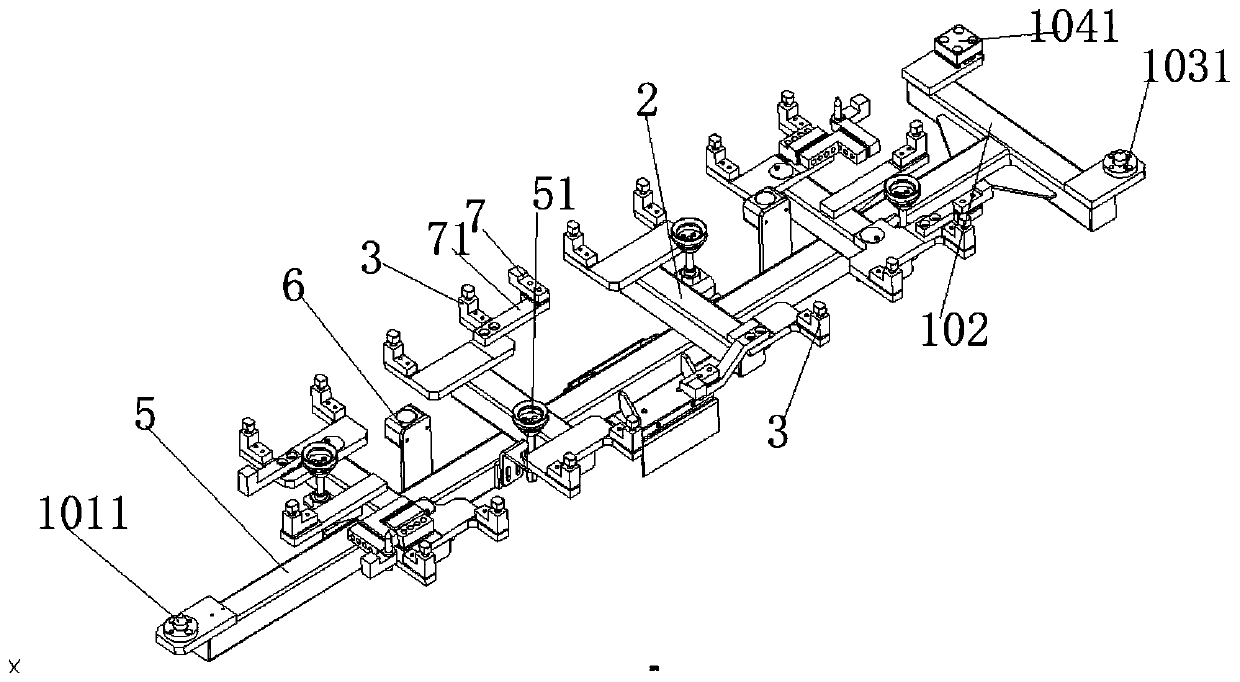

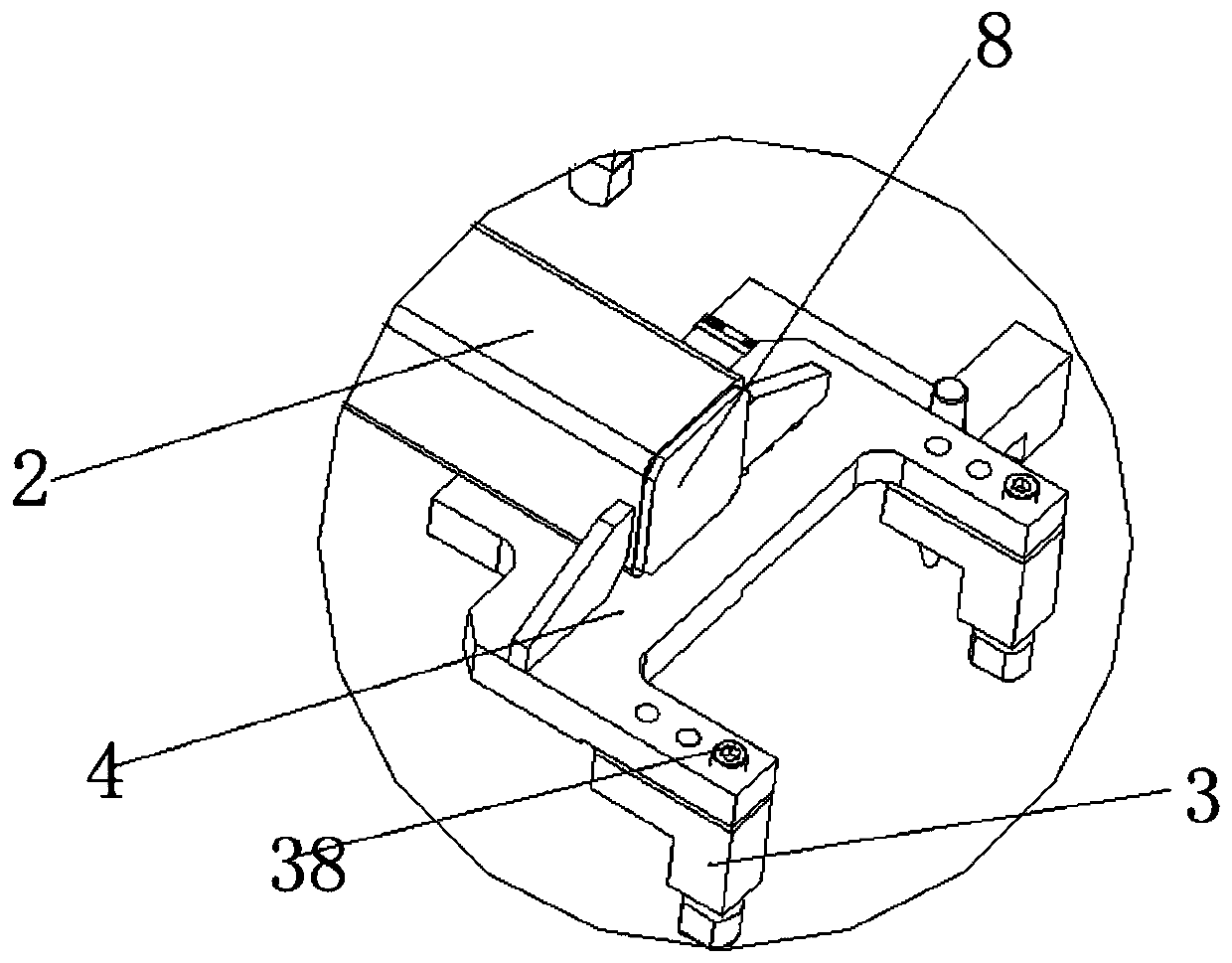

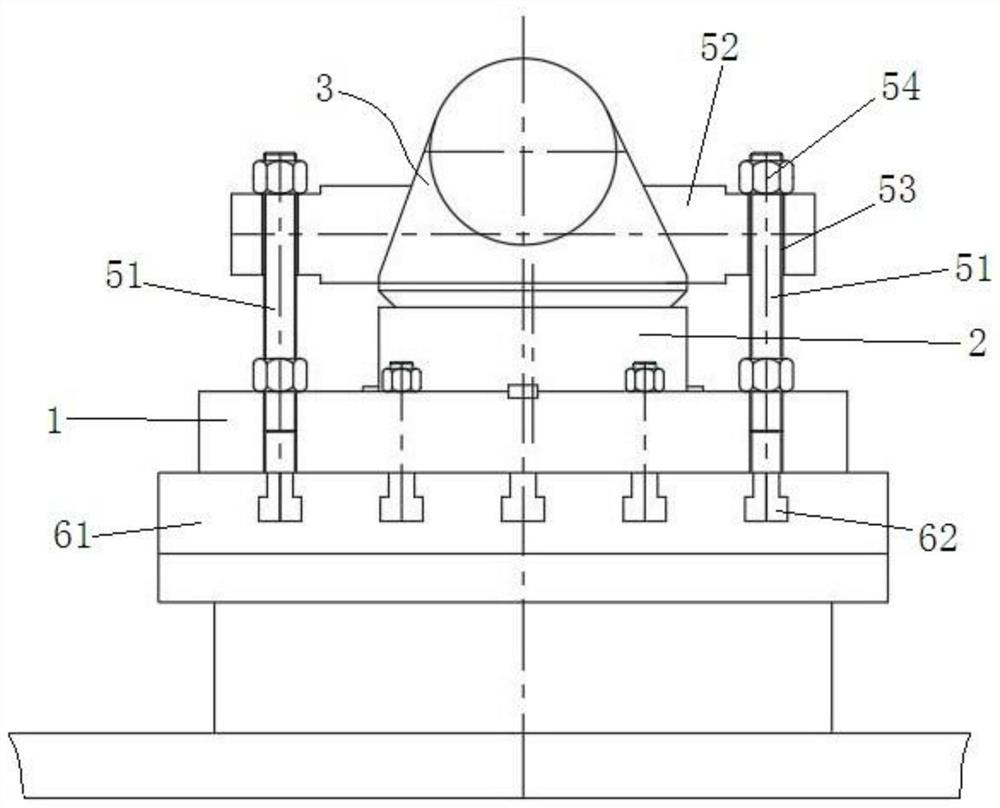

Plate-shaped workpiece tool fixing clamp with original point positioning function and positioning method of plate tool fixing clamp

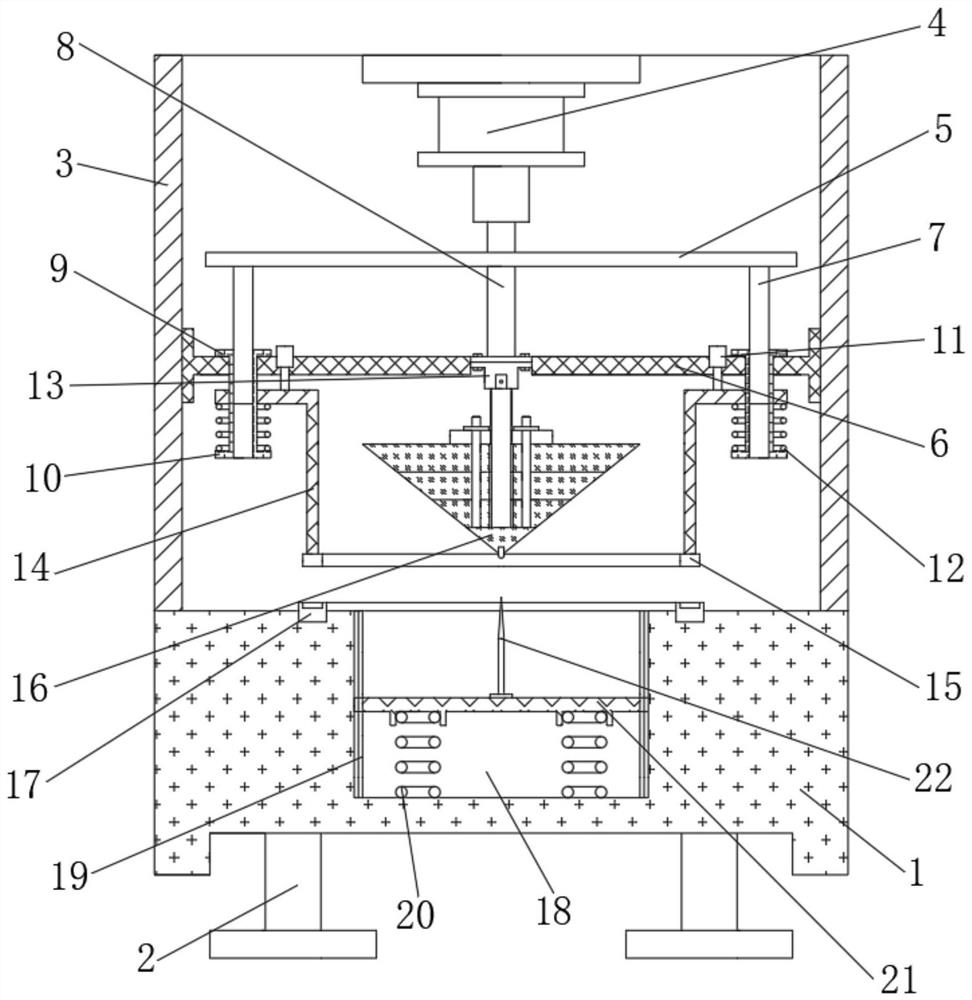

InactiveCN113649837AEasy to fixAchieve squeeze fixationLarge fixed membersPositioning apparatusHydraulic cylinderWorkbench

The invention discloses a plate-shaped workpiece tool fixing clamp with an original point positioning function and a positiong method of the plate tool fixing clamp. The plate tool fixing clamp comprises a workbench, a cross beam transversely driven by a hydraulic cylinder is arranged on the right side of the upper end of the workbench, four sets of extending guide rails which are distributed in a circumferential array and perpendicular to one another are arranged at the upper end of the cross beam, a fastening block is fixedly installed in the middle of the upper end of the cross beam, and transverse clamping blocks are sliably mounted on the pair of transversely arranged extending guide rails which are bilaterally symmetric. The plate tool fixing clamp has the beneficial effects that through the cooperation of the transverse clamping blocks and longitudinal clamping blocks, the original point of a plate-shaped workpiece can be conveniently and rapidly positioned, then sliding of the cross beam is achieved through a hydraulic cylinder while fixed clamping is conducted, the purpose of corresponding to the original point of the tool is achieved, multiple times of position adjustment and clamping are avoided, and the machining precision is greatly improved.

Owner:绍兴市蓝也机械有限公司

Papermaking machine roll shaft joint device

InactiveCN112921699AAchieve positioningAchieve supportPaper-making machinesStructural engineeringIndustrial engineering

A papermaking machine roll shaft joint device comprises a bottom plate and further comprises fixing seats, and a connecting pipe is arranged between the two fixing seats. end fixing pieces are arranged at the two ends of the connecting pipe; a clamping piece is arranged on the upper side of the fixing seat and connected to the outer wall of the connecting pipe; an auxiliary fixing frame is arranged on the upper side of the fixing seat and connected to the side wall of the clamping piece; extrusion pieces are arranged at the upper ends of the two clamping pieces and are connected to the upper side of the connecting pipe; the end fixing piece comprises an outer jacking pipe, and a first protrusion is arranged at one end of the outer jacking pipe. the inner jacking pipe is arranged in an inner cavity of the outer jacking pipe; a first screw rod is screwed on the outer jacking pipe and the inner jacking pipe; a first extrusion block is convexly arranged on the outer wall of the other end of the outer jacking pipe; a second screw rod is screwed on the first extrusion block; a first adjusting seat is arranged on the second screw rod; a first end cover is arranged at the end part of the outer jacking pipe; a second buffer seat is arranged at the edge of the first end cover; and a joint device can axially position the roll shaft of the paper machine.

Owner:梁小洁

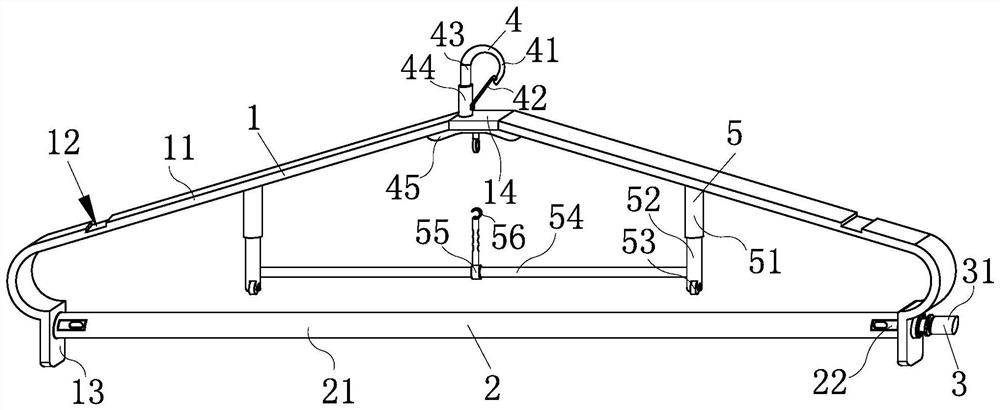

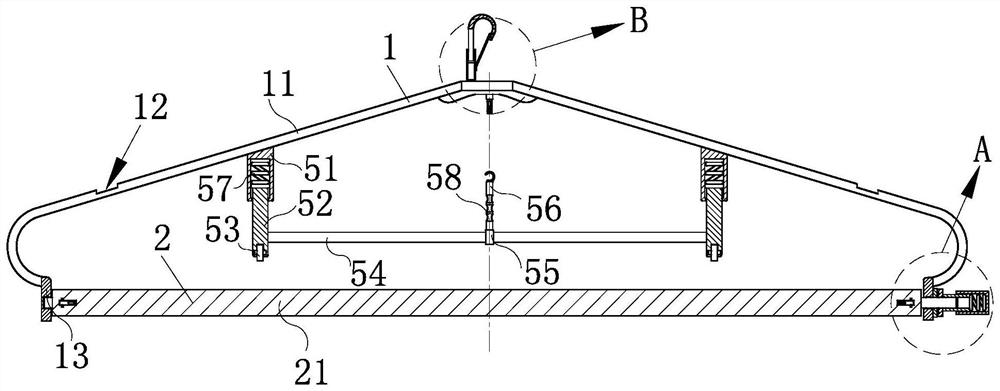

Clothes hanging device for hanging clothes conveniently

ActiveCN111485397BAchieve fixationAvoid blowing offOther drying apparatusTextiles and paperMechanical engineeringIndustrial engineering

The invention relates to the technical field of clothes hanging devices, in particular to a clothes hanging device for hanging clothes conveniently, including a support mechanism, a suspension mechanism, a storage mechanism, a fixing mechanism and a protection mechanism; the inner rotation of the support mechanism is connected with a suspension mechanism to realize To dry long clothes such as towels and bed sheets, the side wall of the suspension mechanism is equipped with a storage mechanism that buckles with the support mechanism. After drying, turn the storage mechanism to realize the winding of towels and bed sheets on the surface of the suspension mechanism. Towels and bed sheets are folded, which reduces the space occupied by the wardrobe; the bottom of the supporting mechanism is equipped with a protective mechanism, which can be loosened when drying, so that the protective mechanism can fit the towels and leaflets on the surface of the hanging mechanism, which is beneficial to towels and bed sheets Fixed to avoid blowing off, the transmission rod can also be neatly rolled up when rolling up, and the protective mechanism can be put away when drying, without affecting the drying of clothes.

Owner:邹木华

Floating positioning mechanism for aluminum alloy laser welding

InactiveCN110153556ASmall amount of deformationAvoid deformationLaser beam welding apparatusWelding deformationMetal

The invention relates to the field of welding equipment, in particular to a floating positioning mechanism for aluminum alloy laser welding; the floating positioning mechanism comprises a positioningblock for contacting with a welding area of a sheet metal part, the positioning block is connected with an adjusting mechanism for floating the positioning block. Through arranging the positioning block, the positioning mechanism provided by the invention can contact with the sheet metal part to be welded, so that the sheet metal part to be welded is pressed, and because of arranging the floatingmechanism, the positioning block can absorb the welding deformation of the sheet metal part generated by the absorption of heat, so the deformation of the welding part of the sheet metal part to be welded can be reduced or avoided.

Owner:ANHUI RUIXIANG IND

A portable numerical control machine tool state monitoring device

ActiveCN113263357BEfficient acquisitionEasy to transportMeasurement/indication equipmentsNumerical controlControl engineering

The invention relates to the field of numerical control machine tool monitoring, in particular to a portable numerical control machine tool state monitoring device, comprising a support and installation column, and further comprising: two sets of rotating telescopic and fixed modules, which are respectively arranged at both ends of the support and installation column; The positioning and installation structure is connected to the support and installation column; the displacement monitoring module is moved and installed on the support and installation column. The combined positioning and installation structure makes the device easy to transport and load and unload. , so that the device can not only adapt to the installation of CNC machine tools with different internal structures, but also can adjust the initial angle. Through multi-axis rotation adjustment and height adjustment, multi-angle monitoring operations can be realized, and displacement can be realized under the action of guiding movement, which further improves the The monitoring range enables the device to efficiently obtain the status of the CNC machine tool.

Owner:吉林大学重庆研究院

Lawn patch repairing device for urban management

InactiveCN110754302AImprove soil loosening effectLoose soil evenlySpadesHops/wine cultivationAgricultural engineeringElectric machinery

The invention belongs to the technical field of urban management, in particular to a lawn patch repairing device for urban management. To solve the problem that a large amount of manpower is wasted for manually repairing the lawn patches at present, the following scheme is provided; the lawn patch repairing device comprises a supporting base, the outer wall of one side of the top of the supportingbase is connected with a sliding frame through bolts, the outer wall of the top of the sliding frame is connected with a top cover through bolts, the outer wall of the middle of one end of the top cover is connected with a rotating motor through bolts, and an output shaft of the rotating motor is connected with a rotating shaft through bolts. According to the lawn patch repairing device for urbanmanagement, a rotating wheel is provided, a transmission belt is arranged on the rotating wheel, the contact area of the lawn patch repairing device with the lawn surface can be increased, and the rotating wheel is prevented from forming grooves in a lawn accordingly; in addition, the transmission belt is provided with breathing holes, so that it can be avoided that gas cavities generated by thetransmission belt to the ground in the rolling process causes bumping to the device in the rolling process.

Owner:湖北增硕建材有限公司

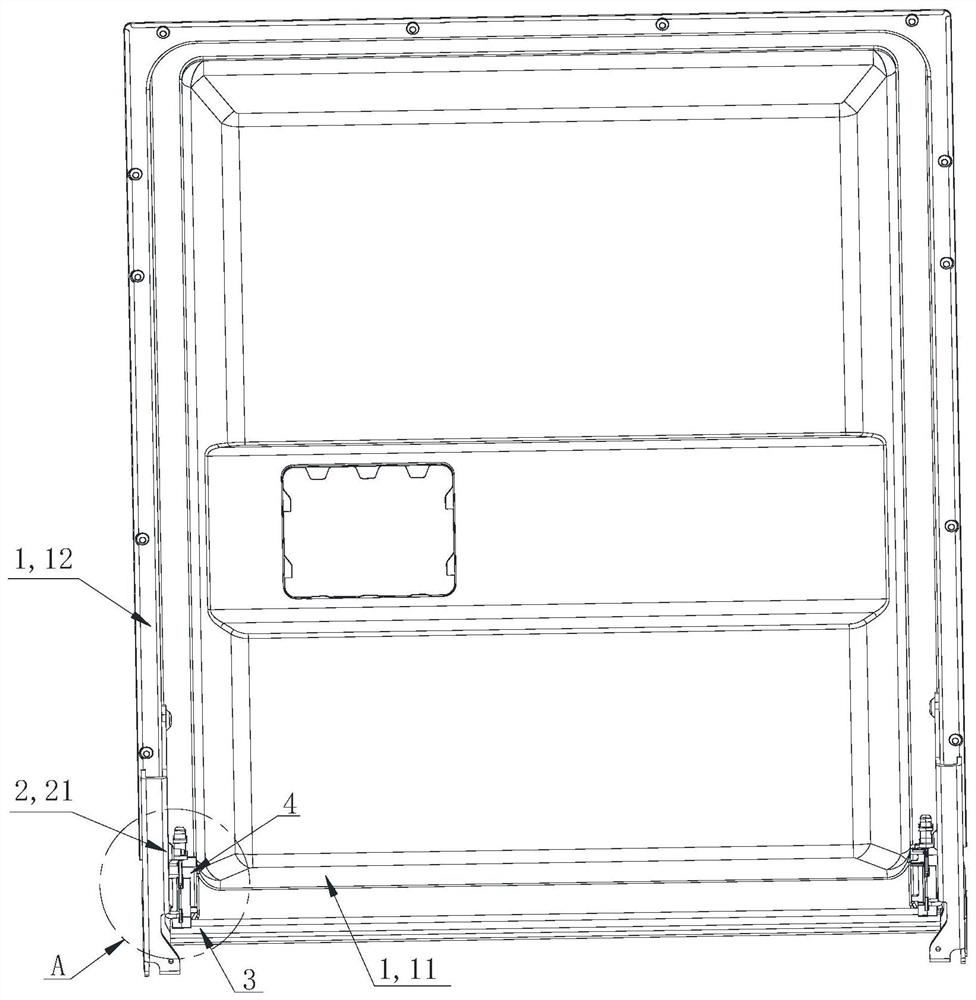

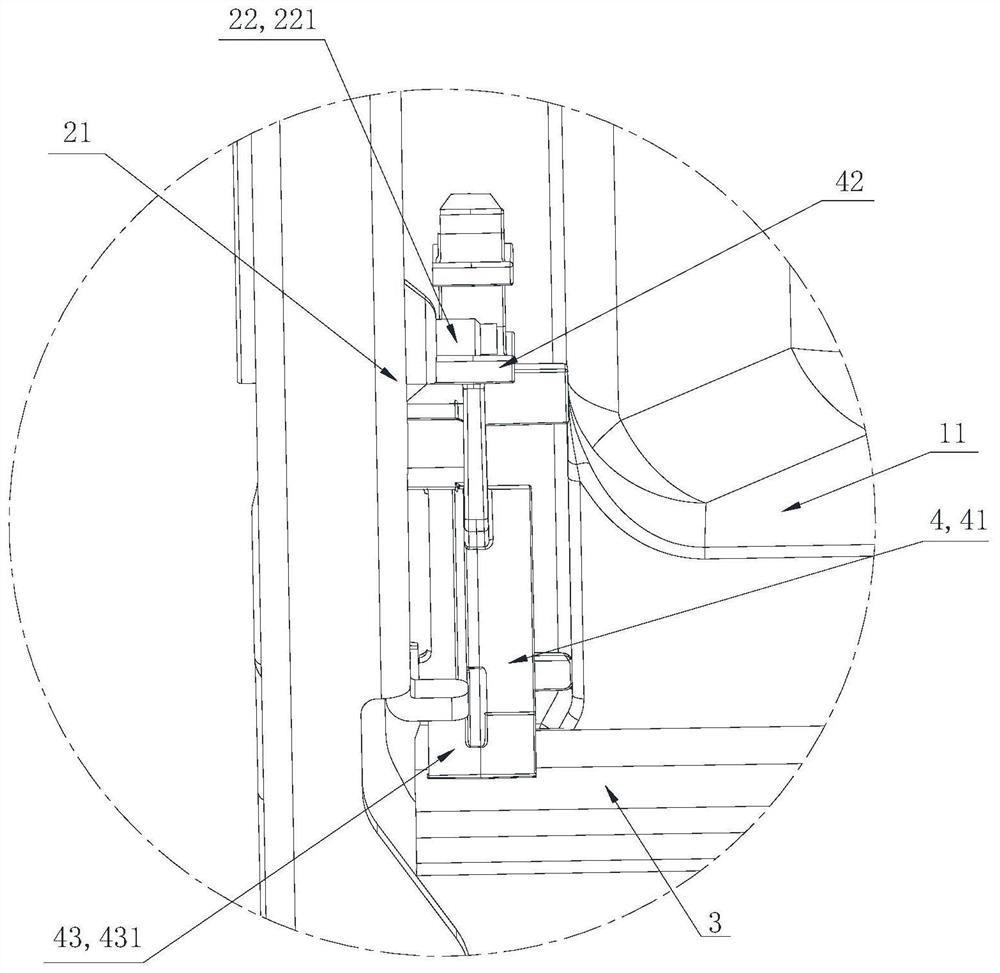

Door body structure and dish washing machine

PendingCN113367632APrevent peelingImprove the fixing strengthTableware washing/rinsing machine detailsStructural engineeringMechanical engineering

The invention discloses a door body structure and a dish washing machine. The invention provides a door body structure which comprises a door body and a door hinge fixed on the door body, a sealing strip is arranged at the bottom of the door body, and the sealing strip is clamped between an extrusion component and the door body. The extrusion component capable of fixing the sealing strip on the door body is arranged on the door hinge so that the situation that two sides of the sealing strip are stripped due to collision and pressing of the door or a shelf is avoided, and the fixing effect on the sealing strip is improved. The invention further provides a dish washing machine which comprises an inner container and further comprises the door body structure in the technical scheme, the door hinge comprises a hinge seat and a hinge arm fixedly connected with the door body, the hinge arm is hinged to the hinge seat, and the hinge seat is fixedly connected with the inner container.

Owner:QINGDAO HAIER DISHWASHER +1

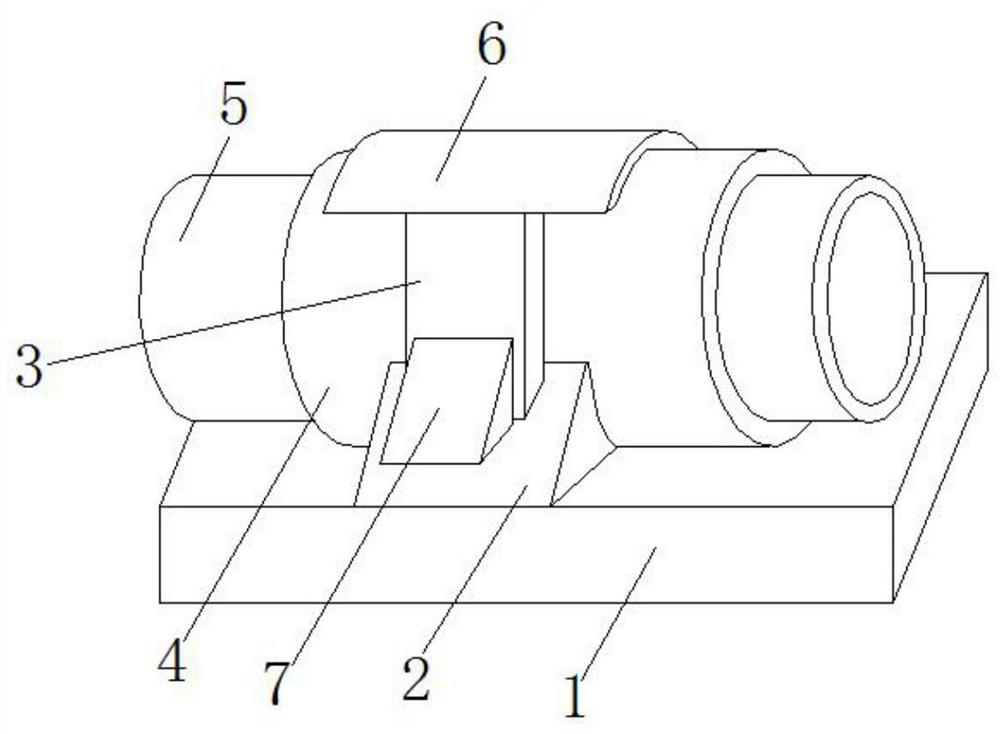

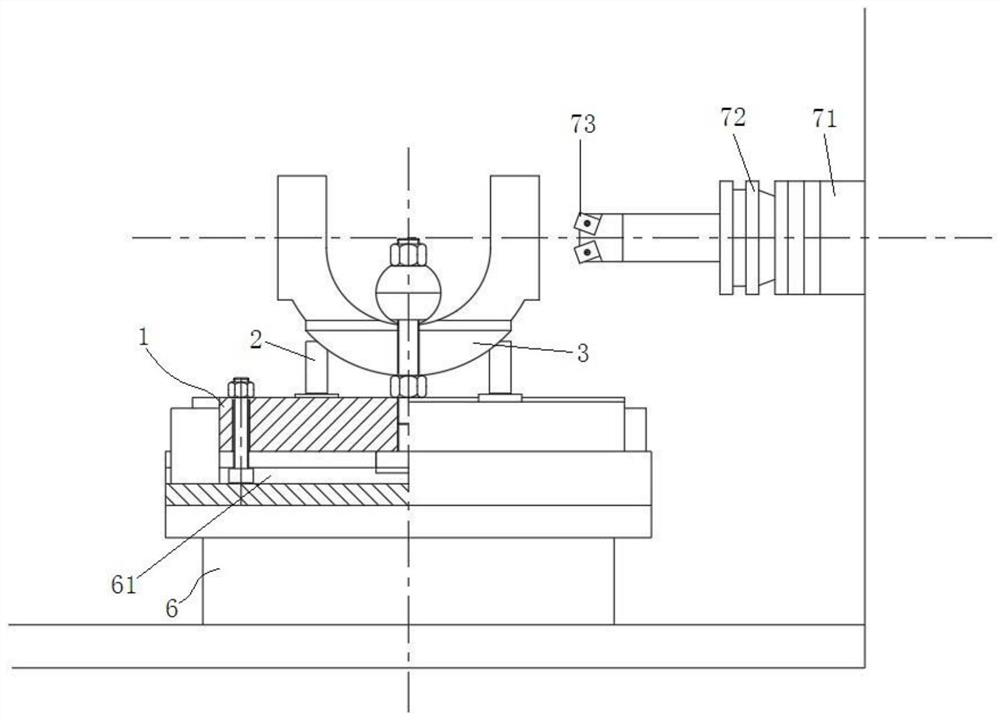

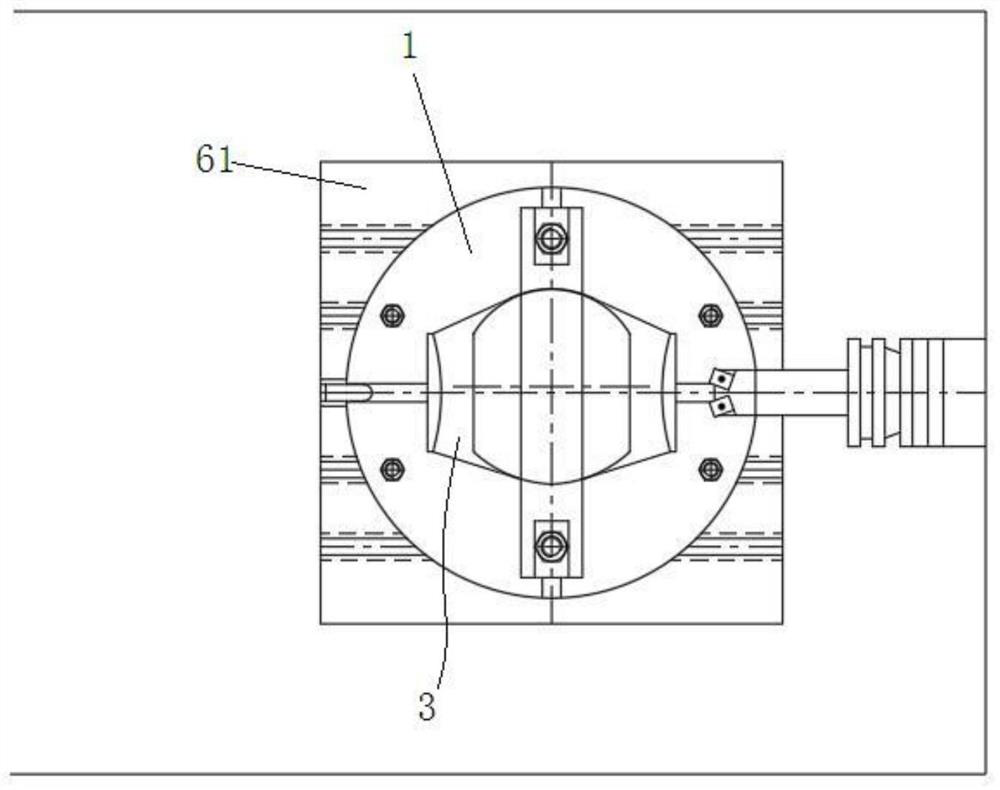

Valve ball fixing device and shaft hole machining device

InactiveCN112404506AEasy to fixAchieve squeeze fixationLarge fixed membersPositioning apparatusMachine toolPhysics

The invention provides a valve ball fixing device and a shaft hole machining device. The valve ball fixing device comprises a bottom disc, a supporting ring and a pressing fixing structure, wherein the bottom disc is suitable for being fixed to a machine tool platform, the supporting ring is fixedly installed on the bottom disc, the top of the supporting ring is used for supporting a semi-spherical surface of a C-shaped valve ball, the pressing fixing structure is also fixedly installed on the bottom disc, the C-shaped valve ball is extruded in the direction from top to bottom, and extrusion fixing of the C-shaped valve ball is realized. According to the valve ball fixing device, firm fixing of the C-shaped valve ball can be conveniently and rapidly realized, preparation is made for shafthole forming operation in the next step, and therefore the fixing difficulty of the C-shaped valve ball can be lowered, and the hole forming efficiency can be improved.

Owner:SHANDONG AFA FLOW CONTROL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com