Floating positioning mechanism for aluminum alloy laser welding

A floating positioning mechanism, laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve problems such as difficulty in breaking through the threshold, blank pure aluminum body, insurmountable cruising range of pure electric vehicles, etc., to reduce deformation volume, avoid the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

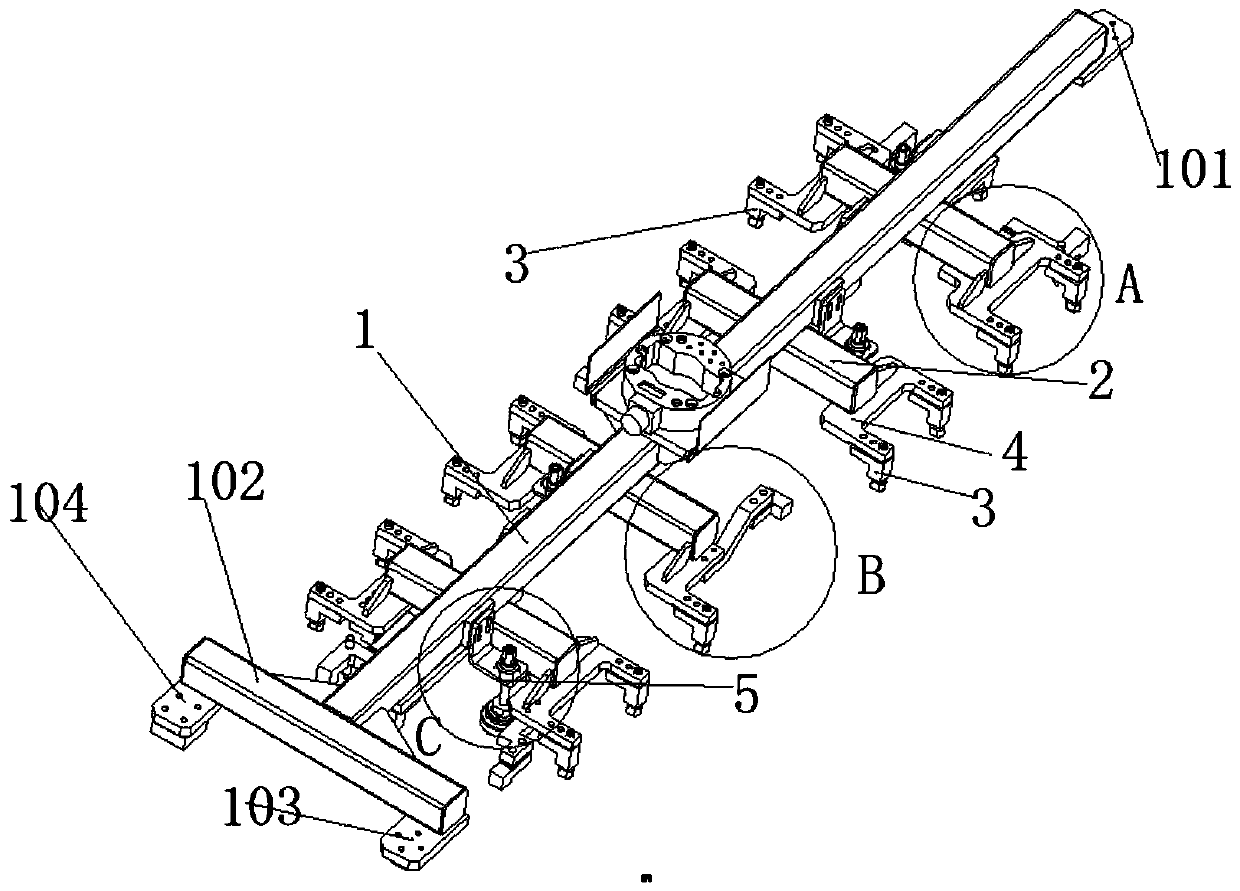

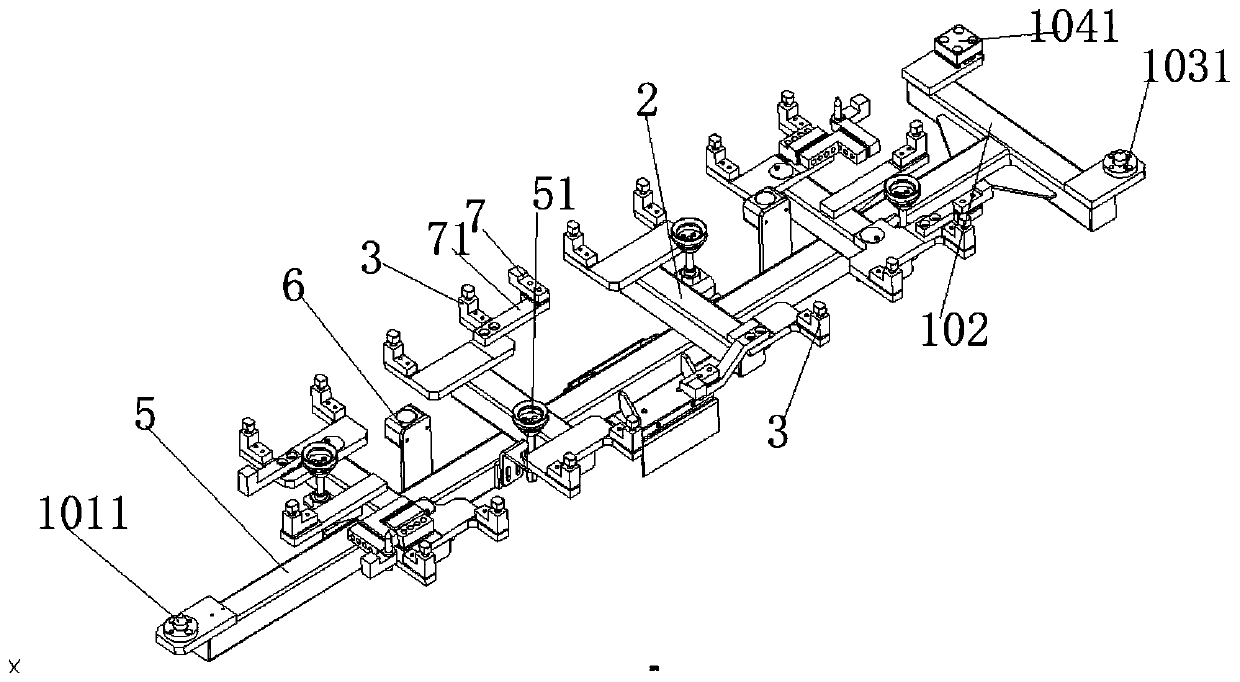

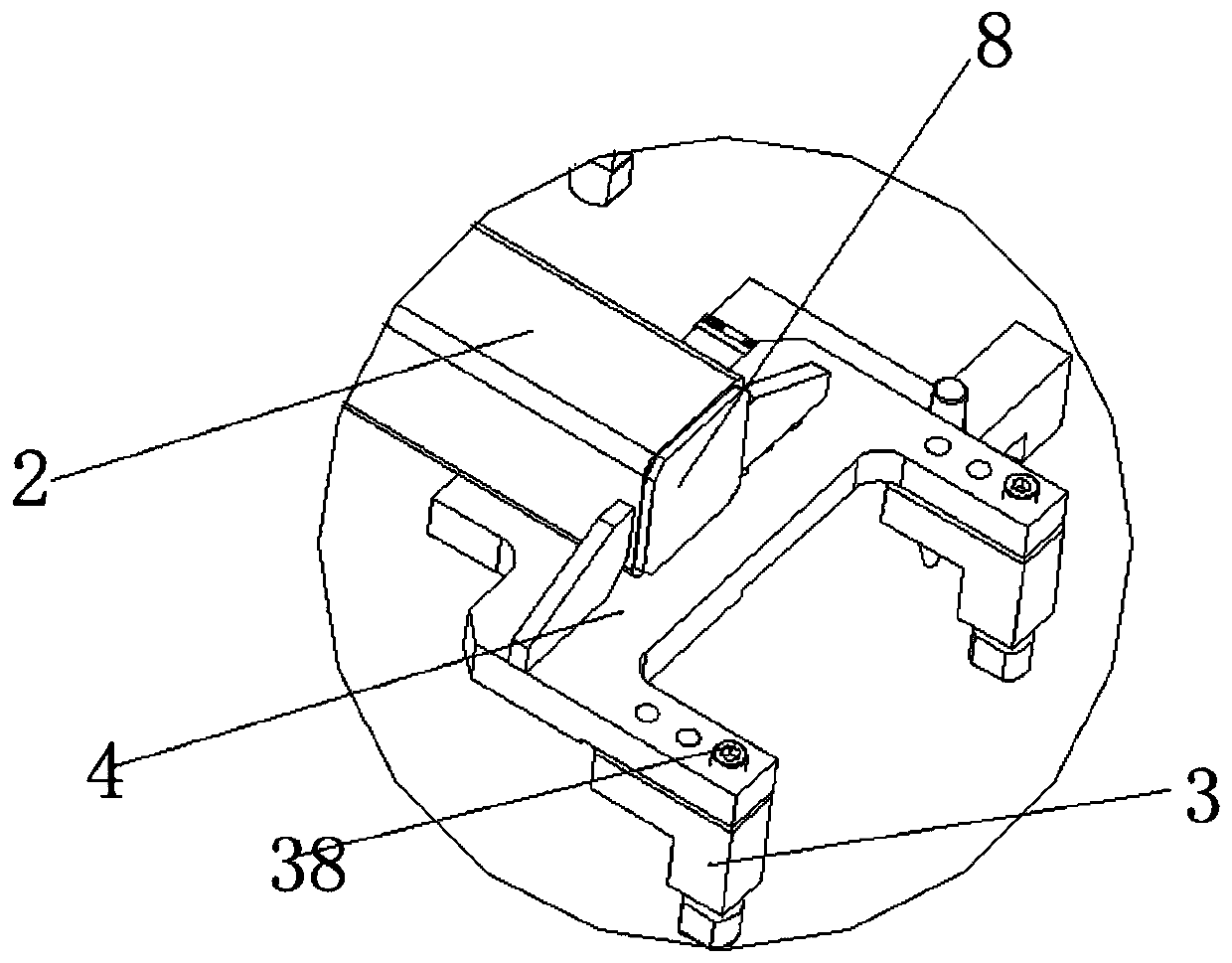

[0028] A floating positioning mechanism for aluminum alloy laser welding, including a support beam 1, on which a cladding beam 2 is provided, and a floating mechanism for contacting the welding area of a sheet metal part 39 is provided on the cladding beam 2 3. The floating mechanism 3 includes a positioning block 31, and the positioning block 31 is connected with an adjustment mechanism for the floating of the positioning block 31; the present invention discloses a positioning mechanism for automobile body welding, and the supporting beam 1 provides for the entire component The foundation of the connection is established; the supporting beam 1 is also provided with a robot switching panel, which is used for the robot to replace different types of mechanisms; at the same time, the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com