Welding device

A technology of welding device and generating device, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., which can solve the problems of affecting welding efficiency and welding quality, easy oxidation of weld seam, poor fixation of welding joints of pipe fittings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

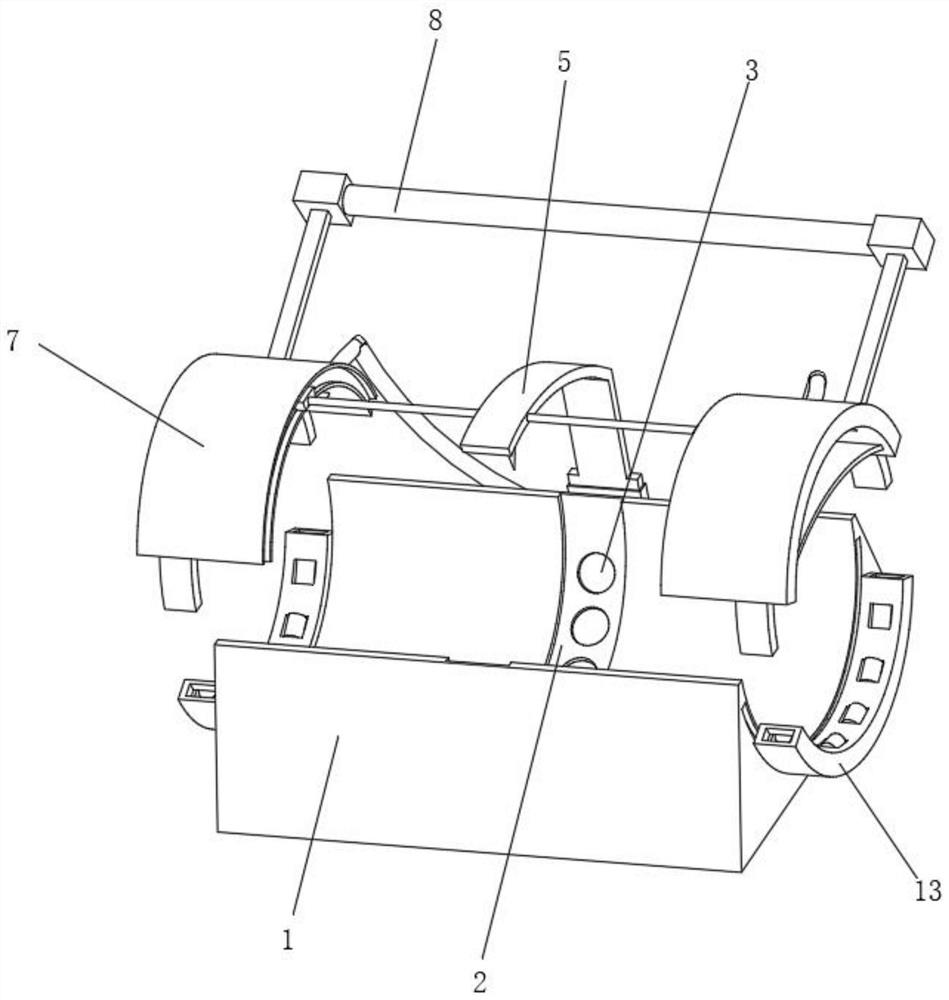

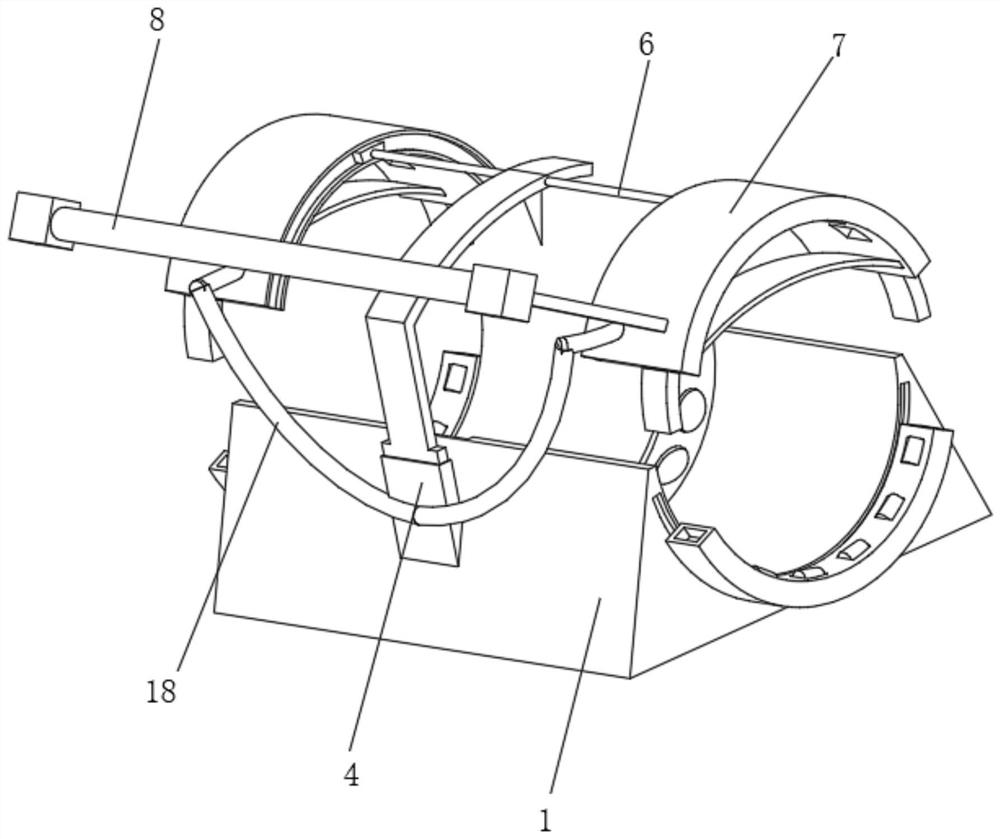

[0043] Such as Figure 1-5 As shown, the present invention provides a technical solution: a welding device, including a welding base 1, the middle position inside the welding base 1 is fixedly connected with a welding regulating groove 2, and the surface of the welding regulating groove 2 is uniformly provided with regulating nozzle holes 3, The middle position on the back of the welding base 1 is fixedly connected with an air pressure generating device 4, and the top of the air pressure generating device 4 is fixedly connected with a welder 5, and the left and right sides of the welder 5 near the top are rotatably connected with a support link 6, and the support link 6 Both sides of the limit plate 7 are provided with a limit plate 7, the side of the limit plate 7 close to the back is fixedly connected with a hand-held control lever 8, and the end of the limit plate 7 near the inner side is fixedly connected with a moving track 9, and the inner sliding connection of the move t...

Embodiment 2

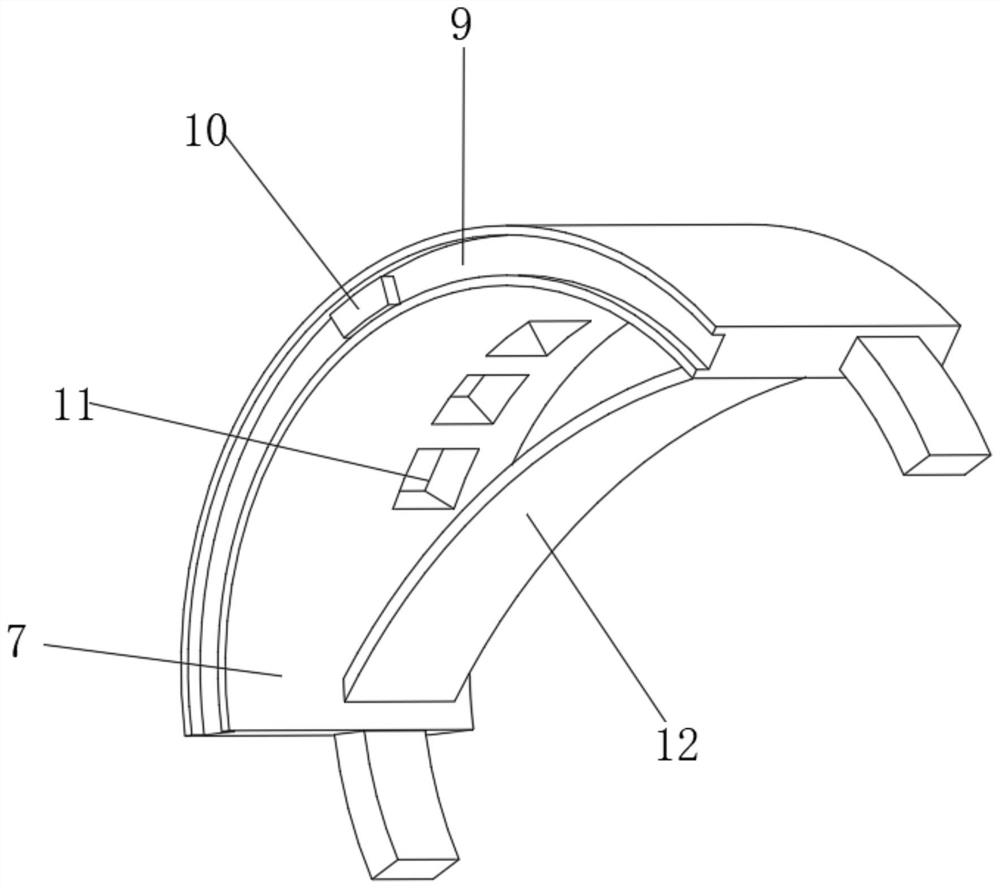

[0048] Such as Figure 6-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the state adjustment mechanism 11 includes a limiting inner groove 111, which is uniformly arranged on the inner surface of the limiting pressure plate 7, and the middle of the inner limiting groove 111 An adjustment drive block 112 is connected to the position rotation, and the adjustment drive block 112 is arranged corresponding to the pressing elastic piece 12 .

[0049] A sealing driving groove 113 is fixedly connected to the inside of the pressing elastic sheet 12 and located on the side of the limiting inner groove 111 , and a driving push plate 114 is slidably connected to the inside of the sealing driving groove 113 .

[0050] One side inside the sealed driving groove 113 evenly runs through and is rotatably connected with a conductive wheel 115 , and one end of the conductive wheel 115 extends to limit the inner groove 111 and is fixedly connected wi...

Embodiment 3

[0054] Such as Figure 8 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a welding device, the air pressure generating device 4 includes a collection inner tube 41, and the bottom of the collection inner tube 41 is fixedly connected to the welding base 1 , the left side outside the collection inner pipe 41 is fixedly communicated with a nitrogen tank 42 . The purpose of ensuring sufficient nitrogen supply and quantitative discharge of nitrogen at the same time is to avoid nitrogen waste.

[0055] The top of the collection inner tube 41 is fixedly connected with a sealed booster tube 43 , the inside of the sealed booster tube 43 is penetrated and slidably connected with a booster drive rod 44 , and the top of the booster drive rod 44 is fixedly connected with the welder 5 . The air around the pipe is blown away, and nitrogen is filled on the surface of the pipe to achieve the purpose of oxygen barrier welding.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com