Casing centralizing device and centralizing method for well completion of horizontal well

A technology for horizontal wells and casings, which can be used in casings, drill pipes, drilling equipment, etc., and can solve problems such as poor quality of casing centering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

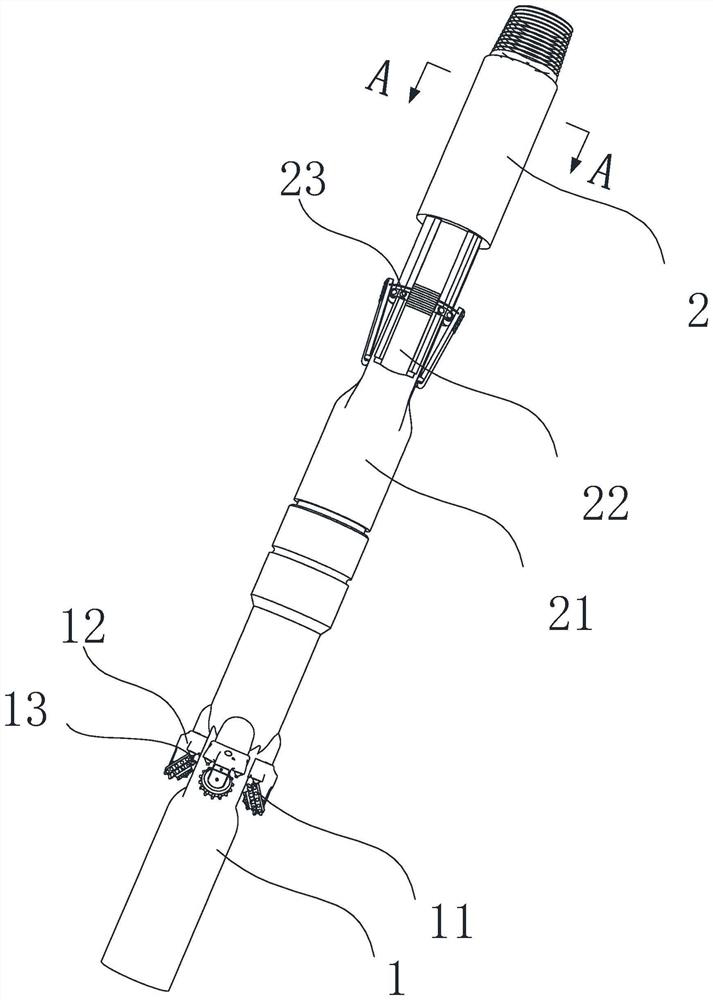

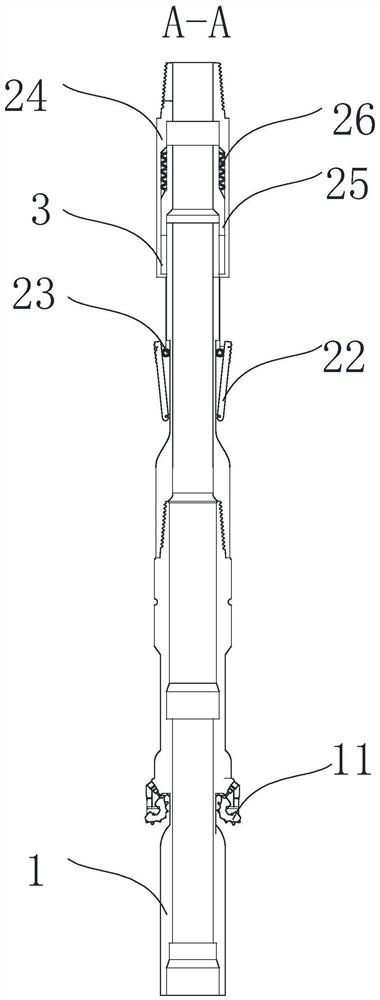

[0040] Such as figure 1 As shown, the casing centralization device for horizontal well completion provided by the present invention includes a reamer 1 and a centralizer 2, the reamer 1 is a cylindrical structure with two ends open, and the outer wall of the reamer 1 is evenly distributed with multiple A cone mount 12, each cone mount 12 is rotatably connected with some cones 11 and water jet nozzles 13.

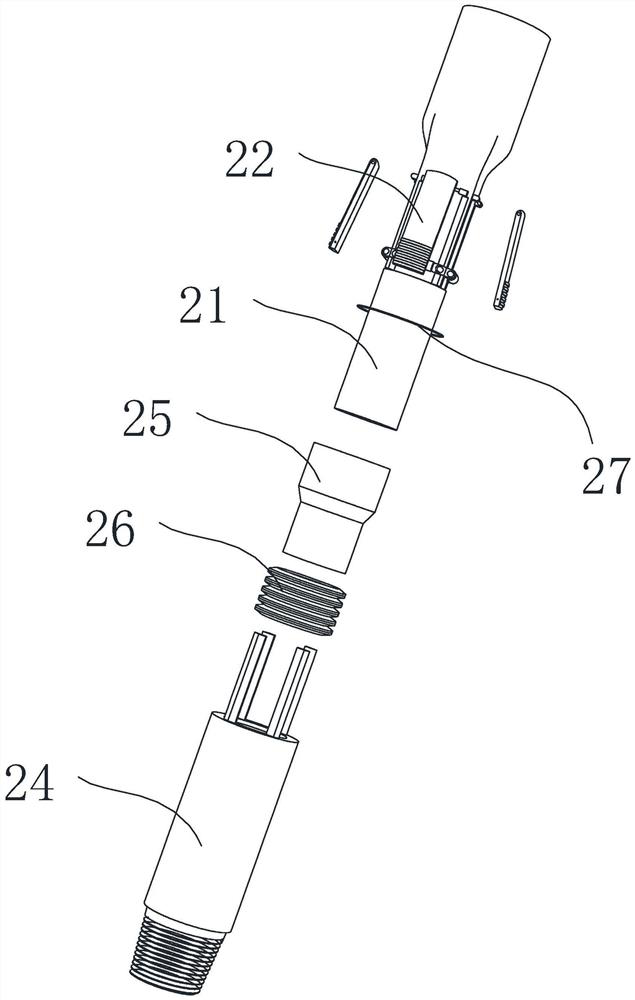

[0041] The centralizer 2 includes a centralizer main body 21, a centralizer slip 22 and a sliding mechanism 23. The centralizer slip 22 is hinged on the outer wall of the centralizer main body 21, and the sliding mechanism 23 is slidably connected with the centralizer main body 21 along the axial direction of the centralizer main body 21. The sliding mechanism 23 and the righting slips 22 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com