Rotating mechanism of bearing platform for detection

A technology of a rotating mechanism and a bearing platform, applied in the direction of the casing of the measuring device, etc., can solve problems such as affecting accuracy and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

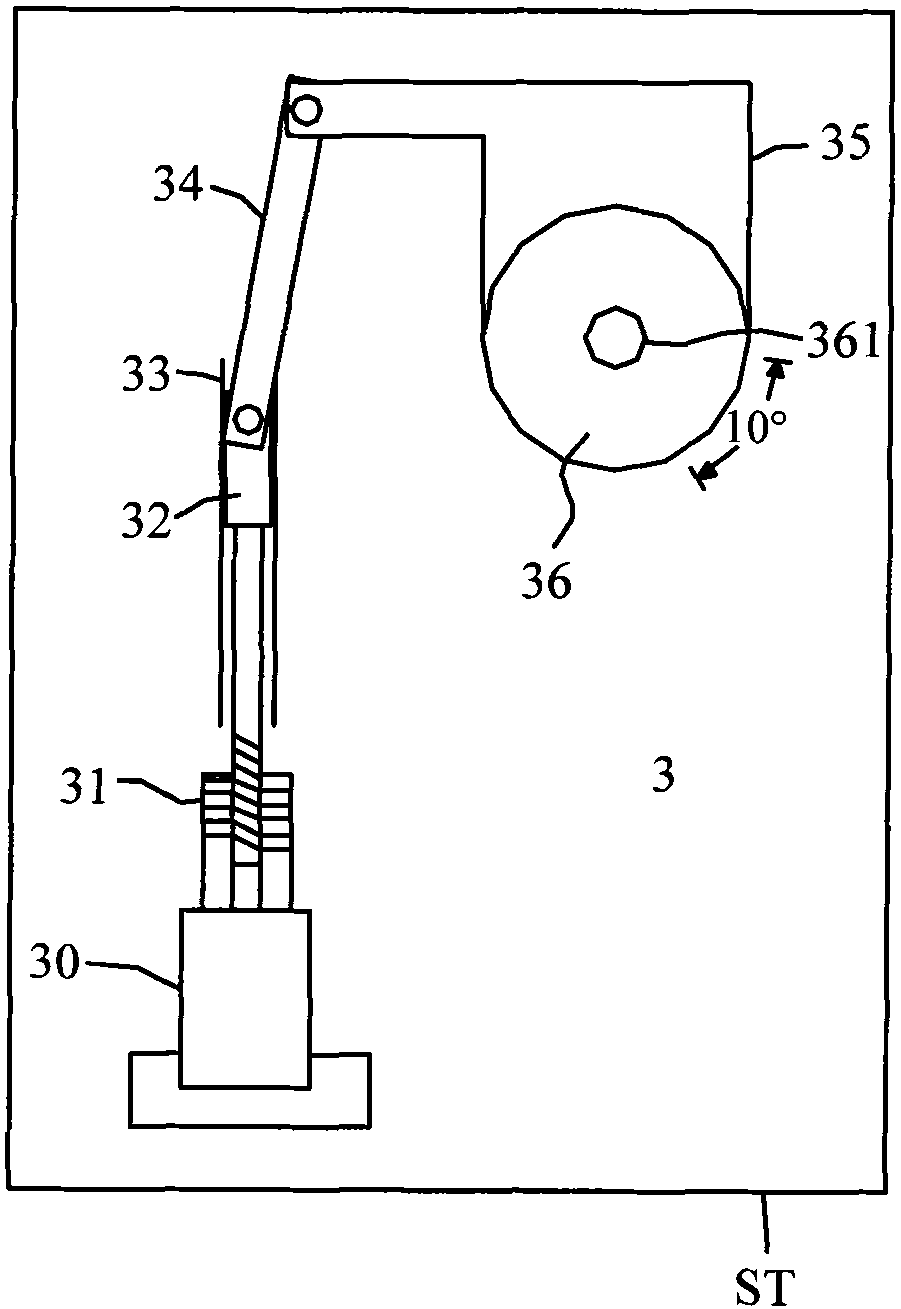

[0048] see image 3 , which is a schematic top view of a first preferred embodiment of the rotation mechanism of the detection carrier proposed by the present invention. exist image 3 Among them, the rotating mechanism 3 is composed of a motor 30, a screw rod 31 that is controlled by the motor 30 to rotate, a slider 32 that is fixedly connected to the screw rod 31 at one end and slides on a slide rail 33, and a connecting rod 34 that is pivotally connected to the slider 32 at one end. , and a crank 35, and the rotating mechanism 3 is fixed on the base ST. Wherein, one end of the crank 35 is pivotally connected to the other end of the connecting rod 34 , and the other end is fixedly connected to the bearing platform 36 .

[0049] Wherein, when the motor 30 operates, the screw rod 31 rotates to push the slide block 32 to slide on the slide rail 33, so that the connecting rod 34 pivots relative to the slide block 32, so that the crank 35 and the bearing table 36 move simultane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com