Valve ball fixing device and shaft hole machining device

A technology for fixing devices and processing devices, applied in positioning devices, large fixed members, metal processing equipment, etc., can solve the problems of difficult fixing, irregular shape of C-type valve balls, poor processing of shaft holes, etc., to achieve convenience and speed Firmly fixed, reducing the difficulty of fixing, and improving the efficiency of opening holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

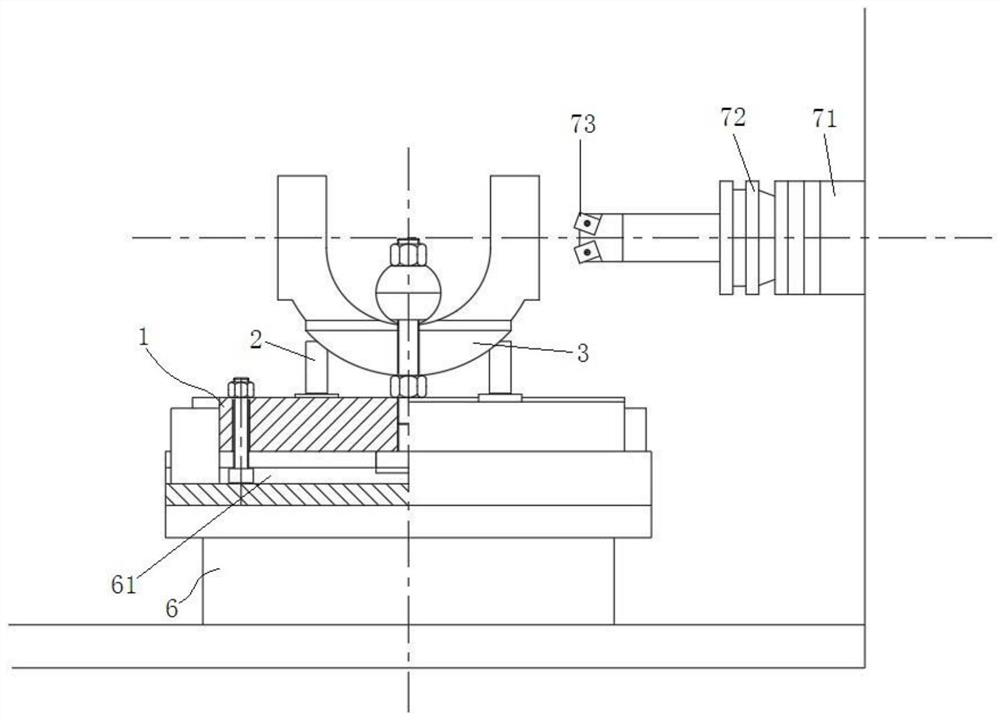

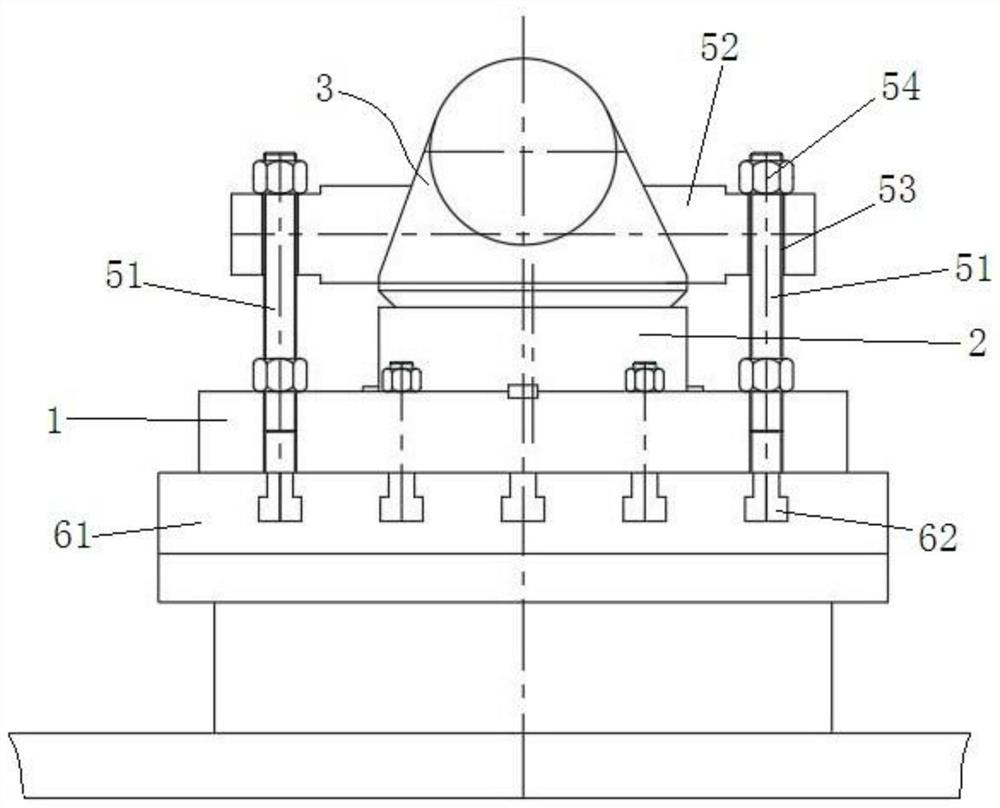

[0053] This embodiment provides a valve ball fixing device, refer to figure 1 As shown, it includes: a chassis 1, a support ring 2 and a press-down fixing structure; wherein the chassis 1 is suitable for being fixedly installed on the machine tool platform 61 of the machine tool 6, and the bottom of the support ring 2 is fixedly installed on the chassis 1 through the first installation structure, An arc-shaped concave ring is formed on the top of the support ring 2 for supporting the hemispherical surface of the C-shaped valve ball 3 .

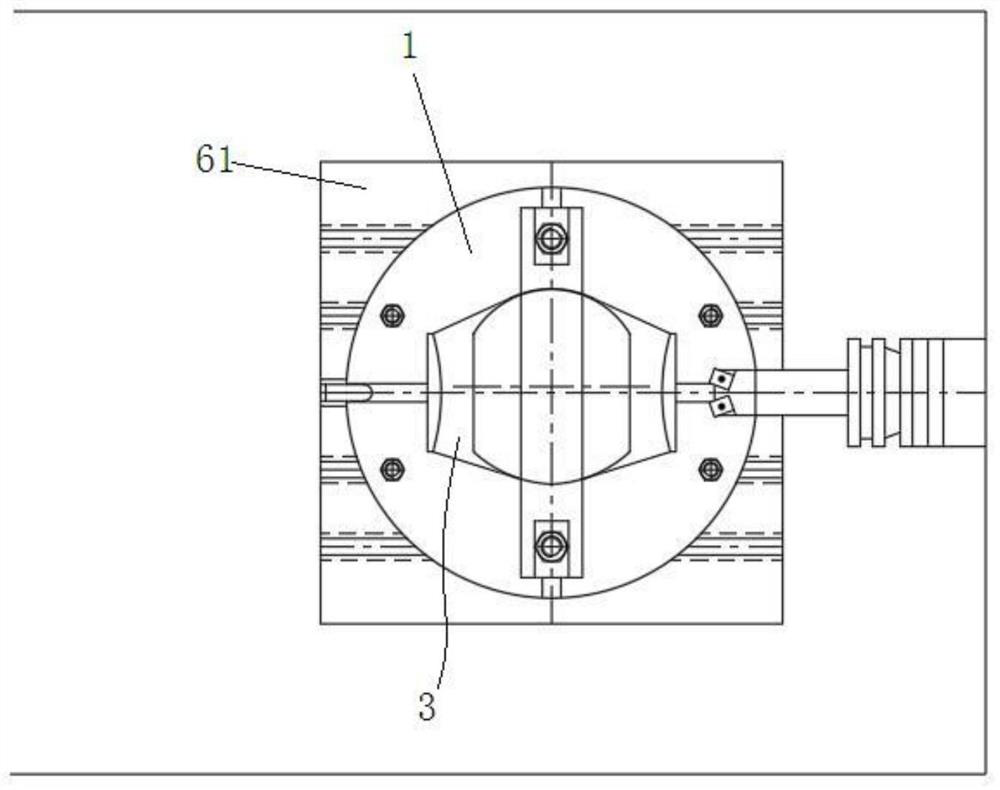

[0054] The position of C-type valve ball 3 after being fixed can refer to figure 2 As shown, the two parts of the C-type valve ball 3 that need to open shaft holes are distributed along the left and right directions in the figure, figure 2 The far right in the figure is the opening mechanism.

[0055] The structure of chassis 1 can refer to Figure 6 with Figure 7 As shown, the bottom of the chassis 1 is provided with a limit cylinder 1...

Embodiment 2

[0064] This embodiment provides a shaft hole processing device, such as figure 1 As shown, it includes a machine tool 6, a valve ball fixing device and an opening mechanism, wherein the valve ball fixing device is the valve ball fixing device described in Embodiment 1.

[0065] Such as image 3 with Figure 8 As shown, several inverted T-shaped through holes 62 are provided on the machine tool platform 61, and the fixed through holes 13 opposite to the inverted T-shaped through holes 62 are provided on the chassis 1, and the bolt assembly passes through the inverted T-shaped through holes 62 and fixed The through hole 13 is used to fix the chassis 1 on the machine tool platform 61 , and then fix the valve ball fixing device described in Embodiment 1 on the machine tool platform 61 .

[0066] The machine tool 6 can drive the machine tool platform 61 to do translational or rotational movements, so that the position where the shaft hole needs to be opened on the C-shaped valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com