Grooving equipment for mold production

A mold and equipment technology, applied in the field of slotting equipment for mold production, can solve problems such as errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

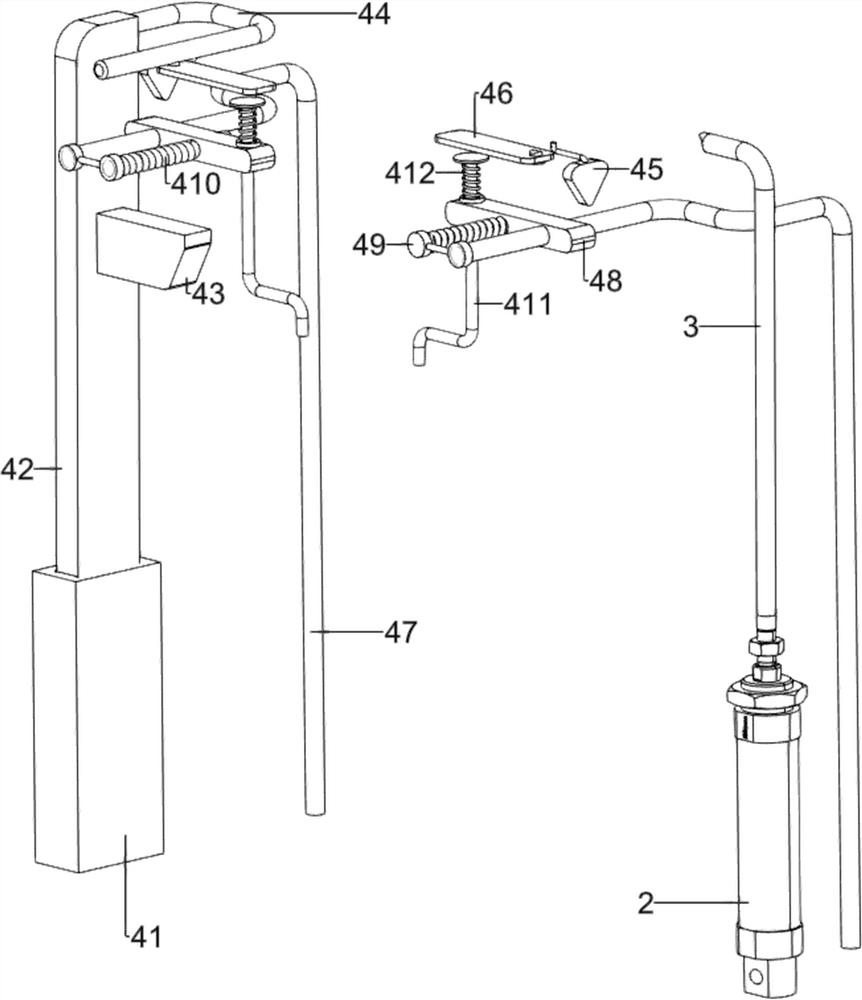

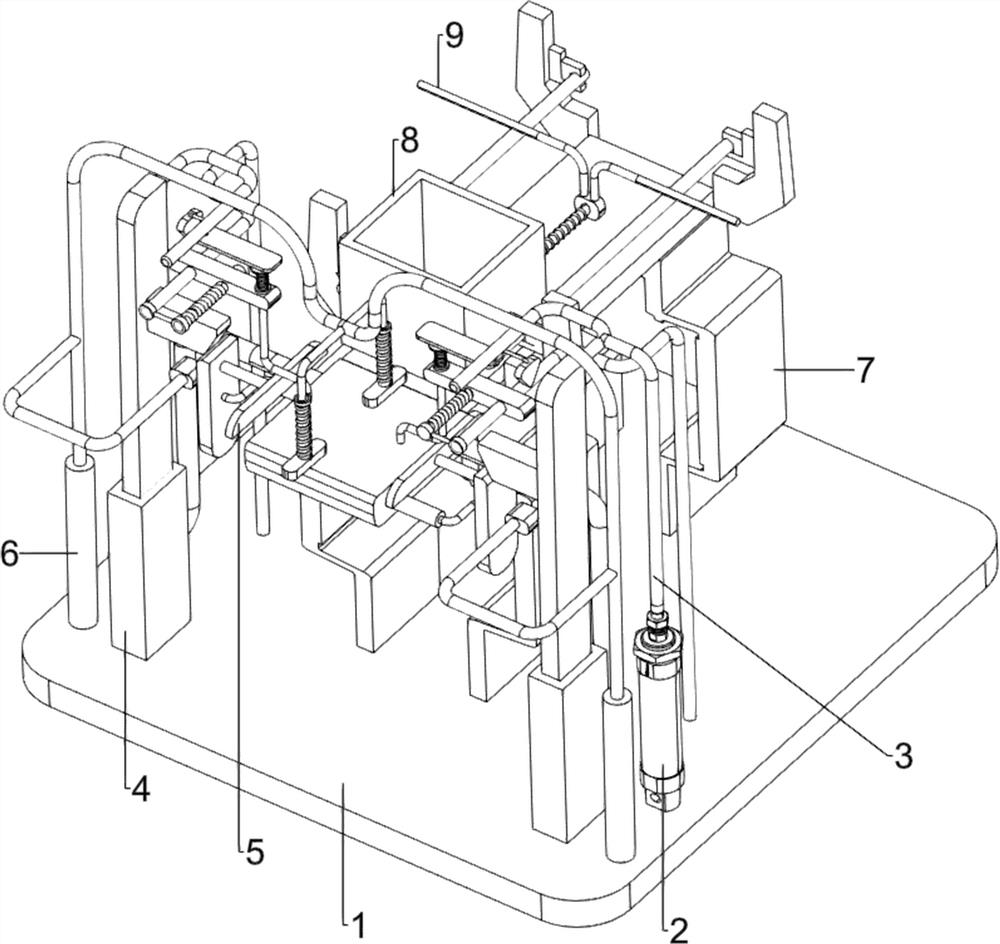

[0024] A slotting equipment for mold production, such as figure 1 As shown, it includes a base plate 1, a cylinder 2, a push rod 3, a slotting mechanism 4 and an alignment mechanism 5. A cylinder 2 is installed on the right side of the upper front of the base plate 1, and a push rod 3 is connected to the top of the cylinder 2. The upper front portion of the base plate 1 A slotting mechanism 4 is provided, and the slotting mechanism 4 is connected with the push rod 3 , and an alignment mechanism 5 is provided on the upper part of the slotting mechanism 4 .

[0025] When people need to slot a production mold, they can use this slotting equipment. First, people put the mold on the alignment mechanism 5, and then open the cylinder 2, which drives the push rod 3 to move downward, thereby driving the slotting Mechanism 4 slots the mold, and the operation of slotting mechanism 4 drives the alignment mechanism 5 to clamp and fix the mold so that it is aligned left and right when slott...

Embodiment 2

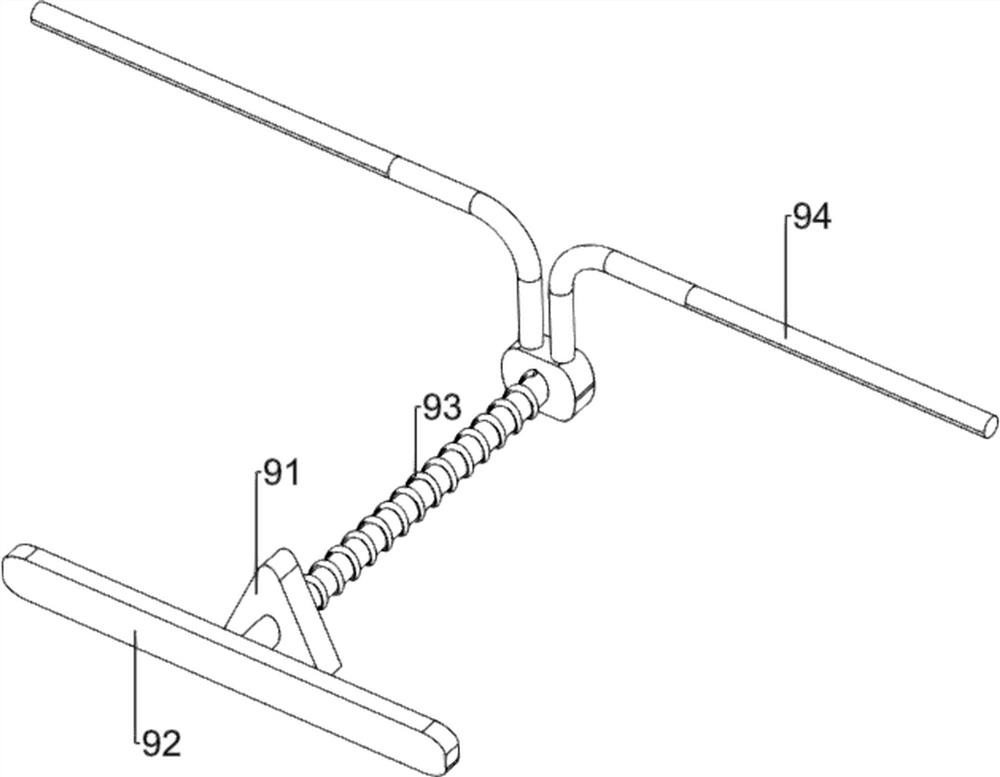

[0027] On the basis of Example 1, such as figure 2 , image 3 and Figure 4 As shown, the slotting mechanism 4 includes a first sleeve 41, a telescopic rod 42, a projection 43, a pressing contact rod 44, a triangular block 45, an elongated square plate 46, a first pole 47, a sliding block 48, a fixed Tool 49, the first spring 410, the scratching knife 411 and the second spring 412, the left and right sides of the upper front part of the bottom plate 1 are all provided with the first sleeve 41, and the two first sleeves 41 tops are all provided with telescopic rods 42, both The inner side of the top telescopic rod 42 is symmetrically provided with a projection 43, and the rear wall of the top of the two telescopic rods 42 is symmetrically provided with a pressing contact rod 44, and the pressing contact rod 44 on the right side is connected with the push rod 3, and the two pressing contact rods 44 front outsides are all provided with triangular block 45, and two downward con...

Embodiment 3

[0032]On the basis of Example 2, such as figure 1 , Figure 5 and Figure 6 As shown, it also includes a pressing mechanism 6. The upper front part of the bottom plate 1 is provided with a pressing mechanism 6. The pressing mechanism 6 includes a second sleeve 61, a first connecting rod 62, a second telescopic frame 63, and a pressure frame assembly. 64 and the fourth spring 65, the left and right sides of the upper front part of the bottom plate 1 are provided with second sleeves 61, and the second telescopic frame 63 is connected between the two second sleeves 61, and the left and right sides of the second telescopic frame 63 middle part The first connecting rods 62 are arranged symmetrically, and the two first connecting rods 62 are matched with the protruding blocks 43 that are close together. A pressure frame assembly 64 is arranged in the middle of the upper part of the second telescopic frame 63, and two first connecting rods are wound around the pressure frame assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com