Distal plug

A distal, cylindrical technology, applied in the field of auxiliary tools for bone cement femoral stem fixation, can solve the problem that the distal plug cannot be satisfied at the same time, and achieve the effect of improving the surgical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

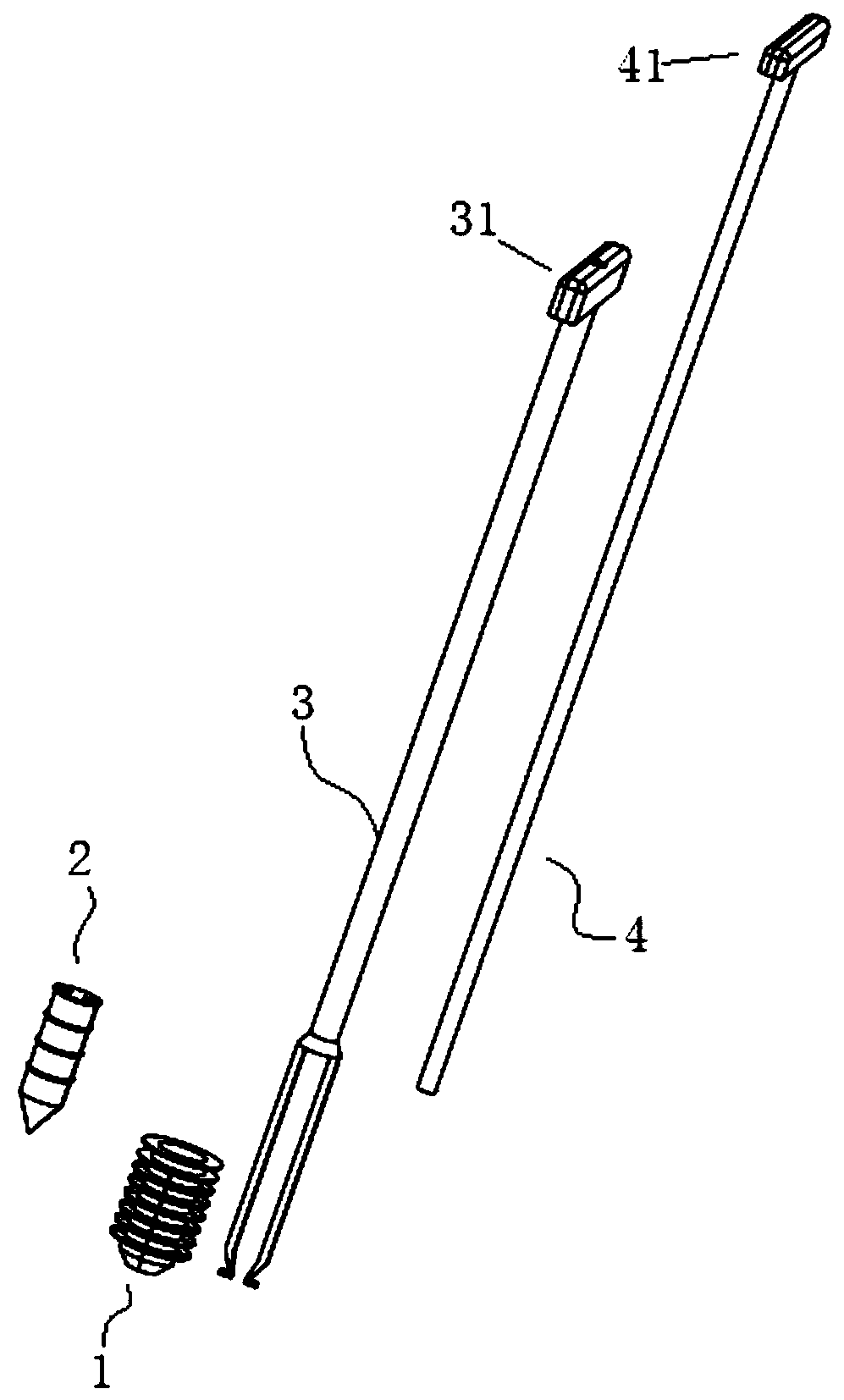

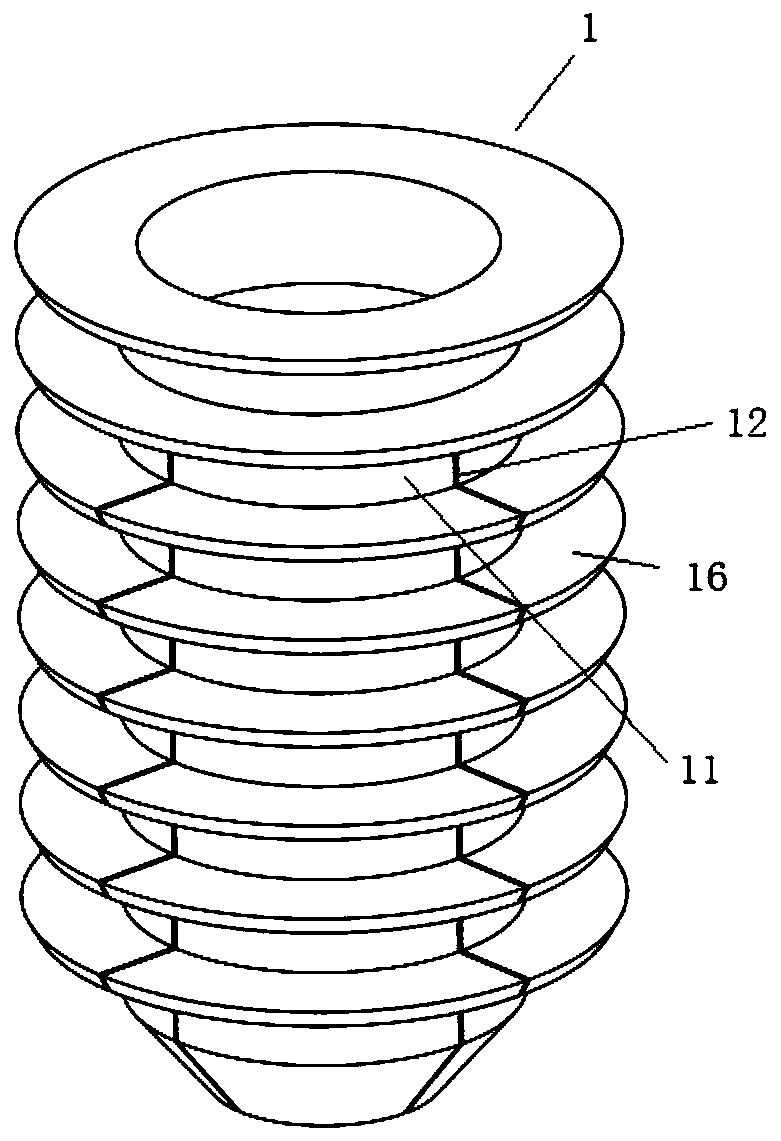

[0059] This embodiment provides a distal plug, such as figure 1 As shown, it includes: a plug sleeve 1, which is hollow, and can expand outward after being squeezed inside; a plug shaft 2, which can be inserted into the plug sleeve 1, and the plug shaft 2 has an initial position and a Squeeze position; at the initial position, the plug sleeve 1 does not expand outward; at the squeeze position, the plug sleeve 1 expands outward under the extrusion of the plug shaft 2; the operating handle 3 can be inserted into the The plug sleeve 1 behind the plug shaft 2 is detachably connected, and the plug sleeve 1 inserted into the plug shaft 2 can be sent to the target position; the driving member 4 is used to apply force to the plug shaft 2. After the external force drives the plug shaft 2 to move from the initial position to the extruding position, it is separated from the plug shaft 2 .

[0060] In the distal plug of this embodiment, after the plug shaft 2 and the plug sleeve 1 are as...

Embodiment 2

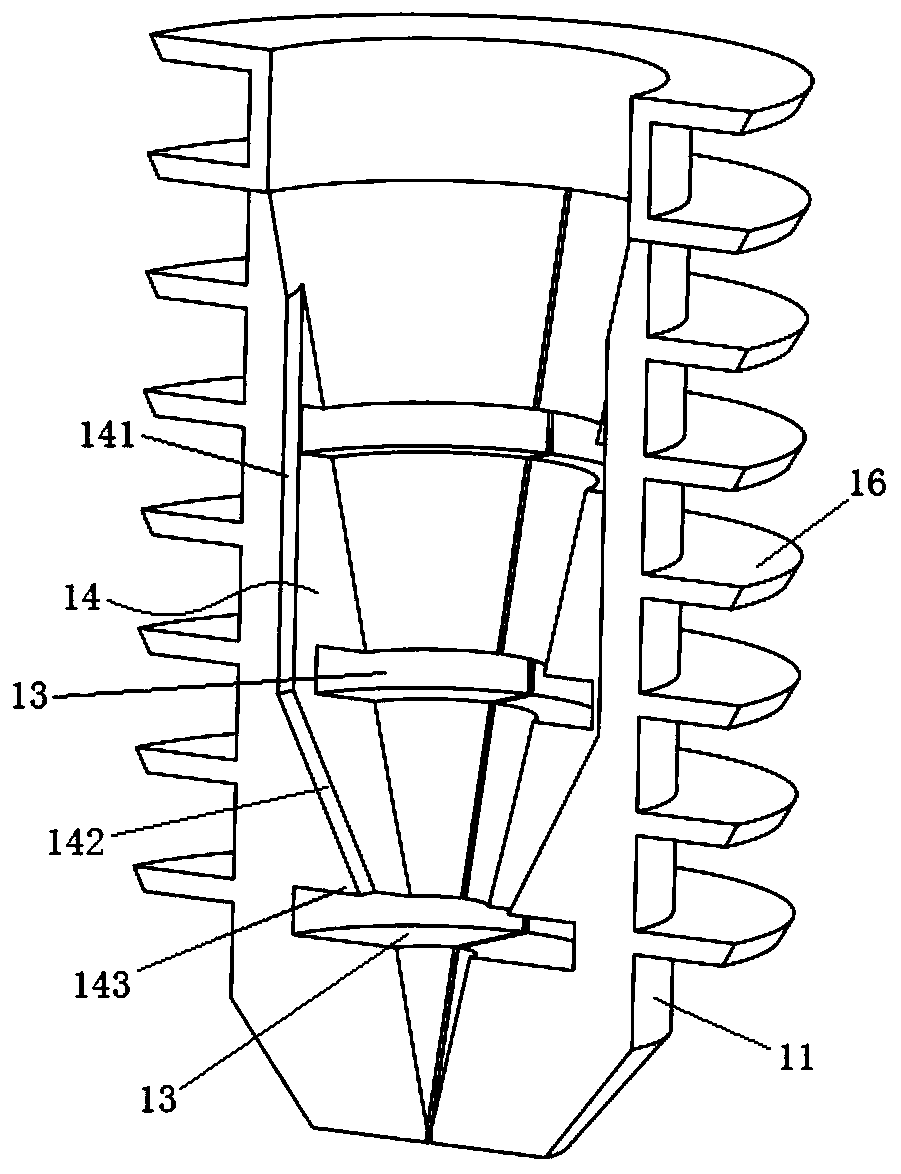

[0074] This embodiment provides a distal plug, which is a deformation based on Embodiment 1, the difference is that: Figure 7 , Figure 8 and refer to figure 2 , Figure 4 , Figure 5As shown, the inner wall of the cylindrical body 11 is provided with at least two first installation grooves 14 extending axially along the cylindrical body 11; the first installation grooves 14 communicate with the anti-off groove 13; The outer wall of the plug shaft 2 is provided with at least two second installation grooves 22 extending axially along the cylindrical body 11; when the first installation groove 14 is turned to face the opening of the second installation groove 22, a aisle;

[0075] The operating handle 3 has an operating end 31 and an inserting end 32, the inserting end 32 is provided with at least two elastic clips 33, the elastic clips 33 are provided with locking teeth 34, and the operating handle 3 passes through the When the passage is inserted into the plug sleeve 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com