A portable numerical control machine tool state monitoring device

A state monitoring device, a technology of numerically controlled machine tools, applied in measuring/indicating equipment, metal processing mechanical parts, metal processing equipment, etc. range, efficient access, ease of transport and handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

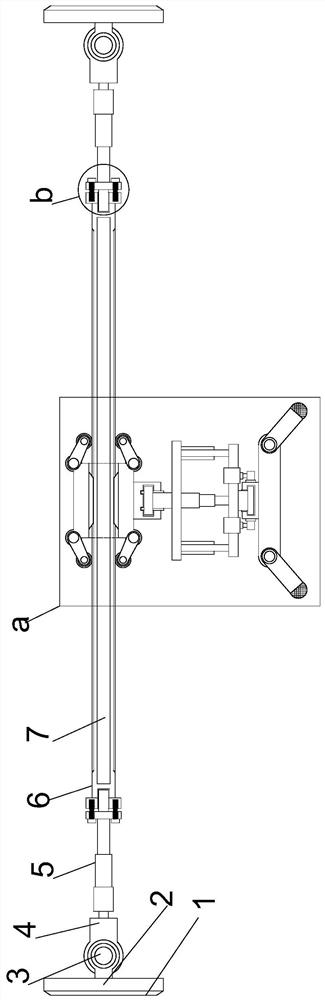

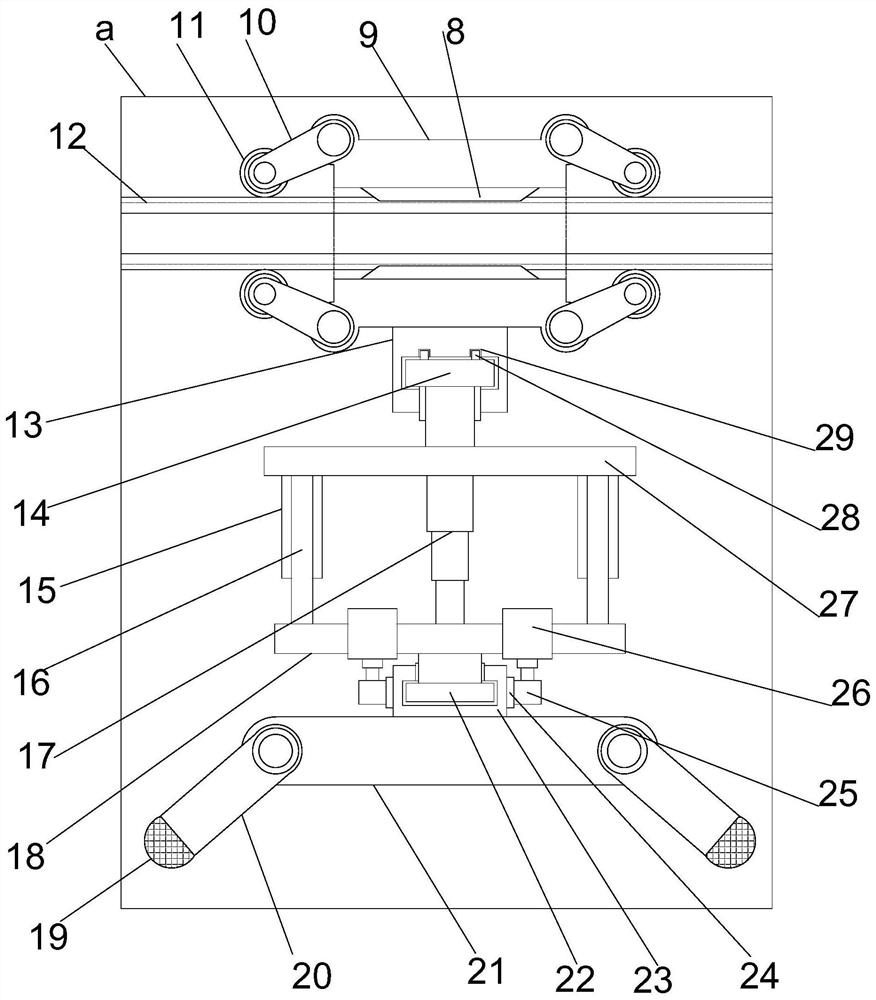

[0028] see Figures 1 to 4 , In the embodiment of the present invention, a portable numerical control machine tool state monitoring device includes a support and installation column 6, and also includes: two sets of rotating telescopic and fixed modules are respectively arranged at both ends of the support and installation column 6; and the rotating and telescopic fixing modules pass through the The positioning and installation structure is connected with the support and installation column 6 ; the displacement monitoring module is moved and movably installed on the support and installation column 6 .

[0029] The moving displacement monitoring module includes a displacement installation cylinder 9, which is movably installed on the support installation column 6, and a sliding conductive column 8 is symmetrically arranged on the inner side of the displacement installation cylinder 9, and the outer side of the support installation column 6 is matched with each other. The slidin...

Embodiment 2

[0032] On the basis of the first embodiment, the rotating telescopic fixing module includes a swing fixing plate 2 , one side of the swing fixing plate 2 is provided with an anti-skid layer 1 , and the other side of the swing fixing plate 2 is provided with a rotating motor 4 through a supporting shaft 3 , the outer end of the rotating motor 4 is provided with an electrically controlled telescopic column 5 through the rotating shaft.

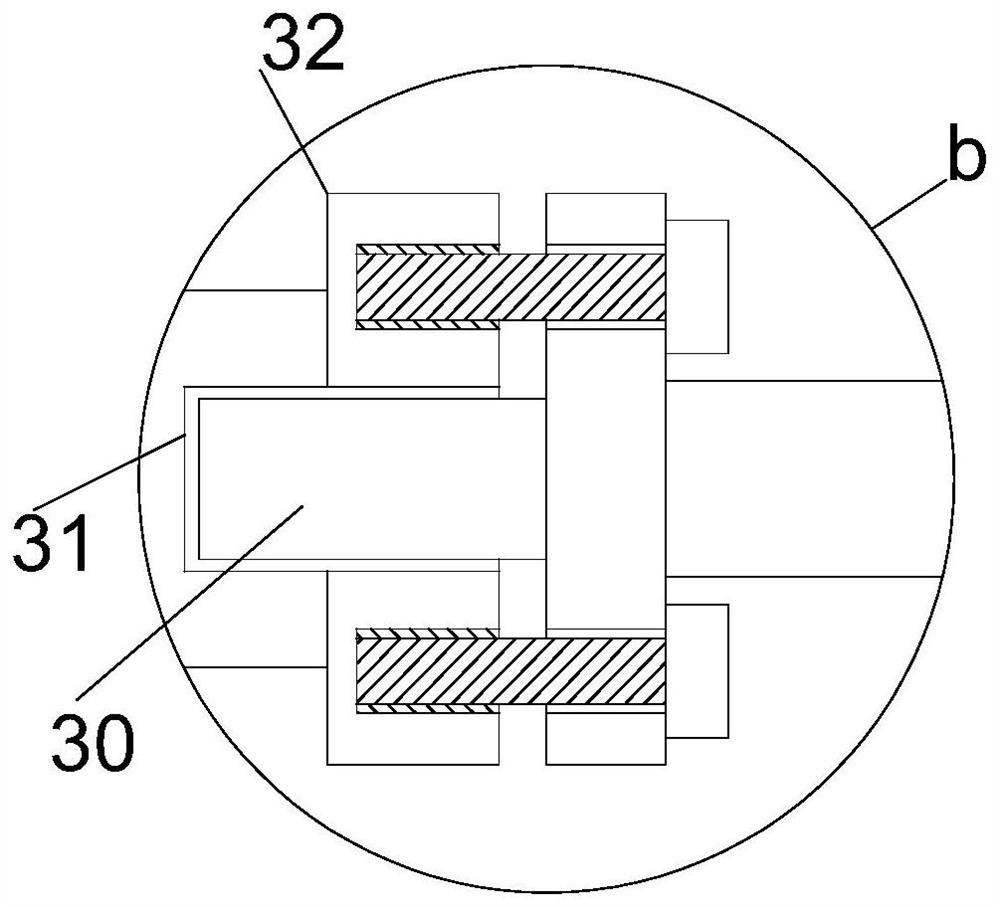

[0033] The positioning and mounting structure includes a fixed mounting plate 32 which is arranged facing each other. The fixed mounting plate 32 is respectively arranged on the electrically controlled telescopic column 5 and the supporting mounting column 6, and a positioning mounting column 30 is arranged in the middle of the fixed mounting plate 32 on one side. The fixed mounting plate 32 on the other side cooperates with the positioning mounting post 30 and is provided with positioning mounting holes 31 . The opposite fixed mounting plate 32 is...

Embodiment 3

[0036] On the basis of the second embodiment, the monitoring sensor 19 may be CSM-EKL3, CSM-SL3, etc.;

[0037] The anti-skid layer 1 can be a rubber layer, resin, etc.;

[0038] The energy storage member 7 may be a battery, a fuel generator, or the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com