Shot peening strengthening device capable of improving stress distribution on surface of gear

A technology of shot peening and surface stress, which is applied in the direction of chemical instruments and methods, cleaning methods using tools, cleaning methods and appliances, etc., can solve the problem of not having stains on the surface of gears, insufficient uniformity of projectile spraying on gears, and removal and handling of gears. Problems such as the complicated operation of the upper part, to achieve the effect of simple structure, improved strengthening effect, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

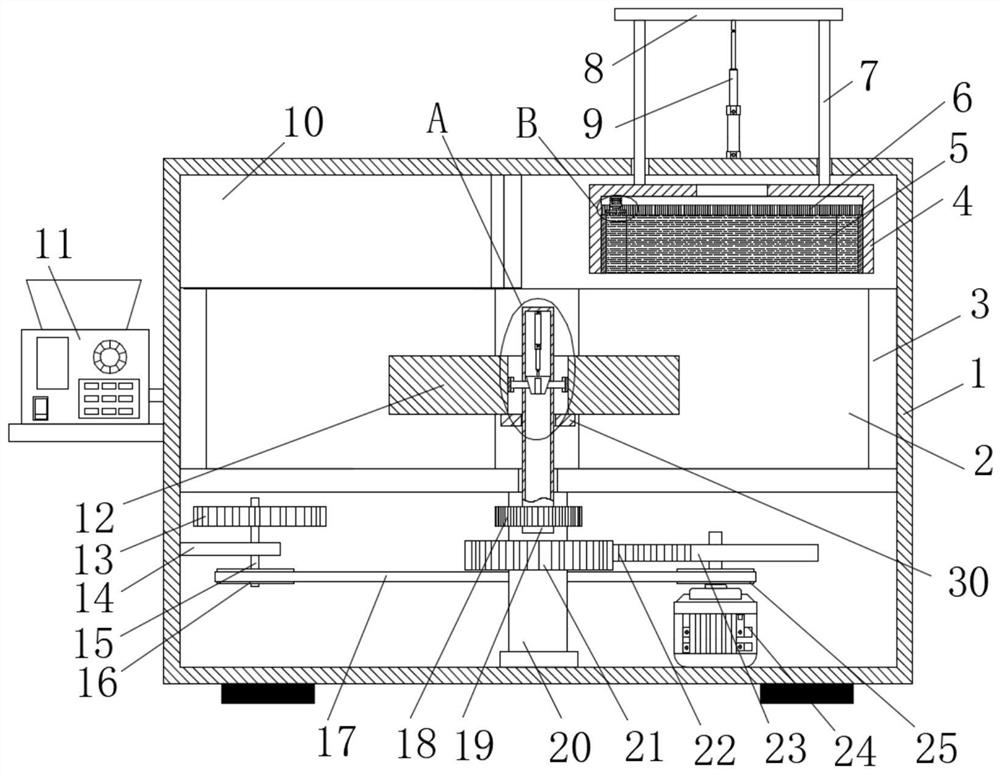

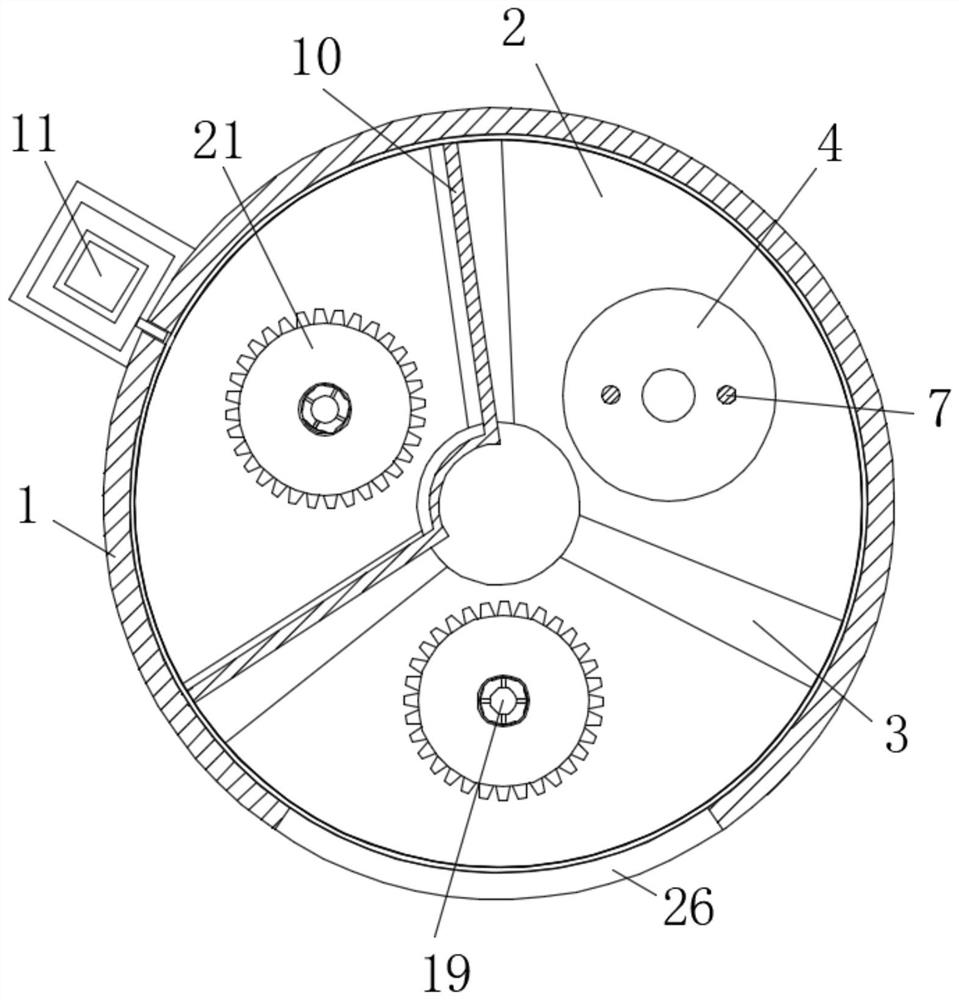

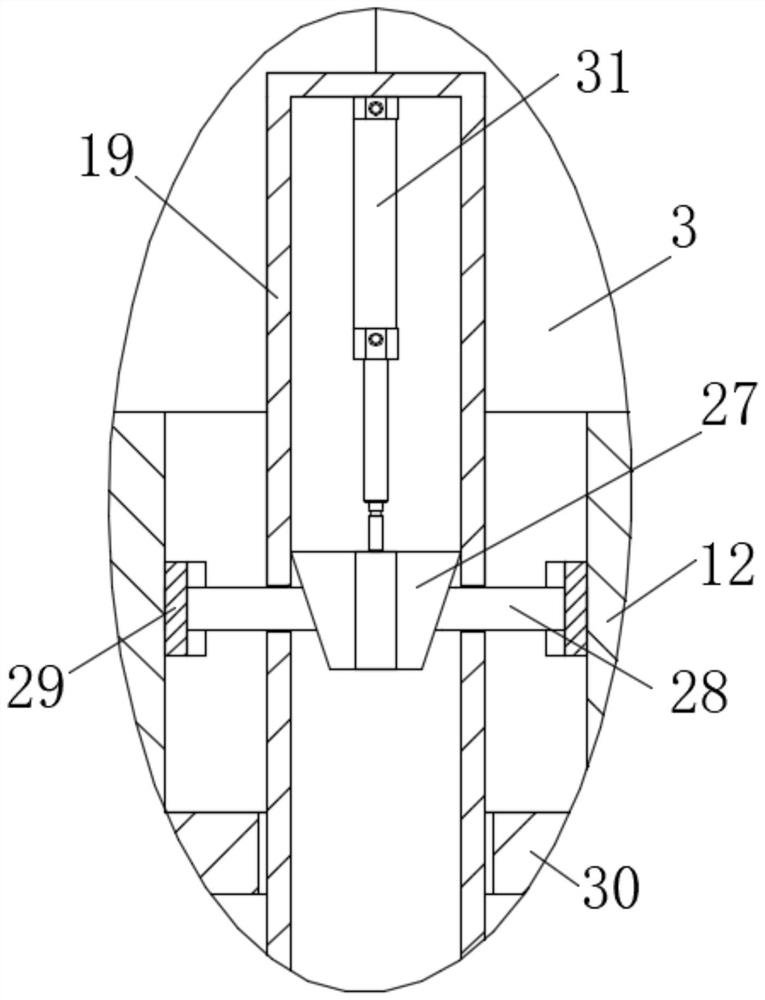

[0029] refer to Figure 1-7 , a shot peening device that can improve the stress distribution on the surface of gears, including a box body 1, the inner wall of the box body 1 is rotatably connected with a blade disk 3, and the box body 1 is provided with a power assembly that drives the blade disk 3 to rotate intermittently. Three fan-shaped chambers 2 are evenly arranged on the disk 3, and the bottom inner wall of the fan-shaped chamber 2 is connected with an inner hollow pipe 19 through rotation, and a retaining ring 30 is fixedly sleeved on the outer wall of the inner hollow pipe 19, and the top of the retaining ring 30 is placed There is a gear 12 to be strengthened that is set on the outer wall of the inner hollow tube 19. The inner hollow tube 19 is provided with a fixing assembly for fixing the gear 12 to be strengthened. The outer wall of the inner hollow tube 19 is fixedly sleeved with a second gear 18. 1 is provided with a transmission assembly that drives the second...

Embodiment 2

[0031] refer to Figure 1-7, a shot peening device that can improve the stress distribution on the surface of gears, including a box body 1, the inner wall of the box body 1 is rotatably connected with a blade disk 3, and the box body 1 is provided with a power assembly that drives the blade disk 3 to rotate intermittently. The assembly includes a first motor 24 fixedly connected to the inner wall of the bottom of the box body 1, a rotating disk 23 is fixedly sleeved on the output shaft of the first motor 24, and the bottom of the blade disk 3 is fixedly connected to the bottom inner wall of the bottom of the box body 1. Rotating roller 20, the outer wall of rotating roller 20 is provided with a third gear 21, and the outer wall of rotating disc 23 is provided with an arc-shaped rack plate 22 meshed with the third gear 21, which is driven by the first motor 24. The intermittent rotation of the rotating roller 20 drives the rotation of the blade disc 3 to realize the rotary ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com