Novel printing machine for Chinese literature books

A printing machine and literature technology, applied in the field of new printing machines for Chinese literature books, can solve problems such as printing failure and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

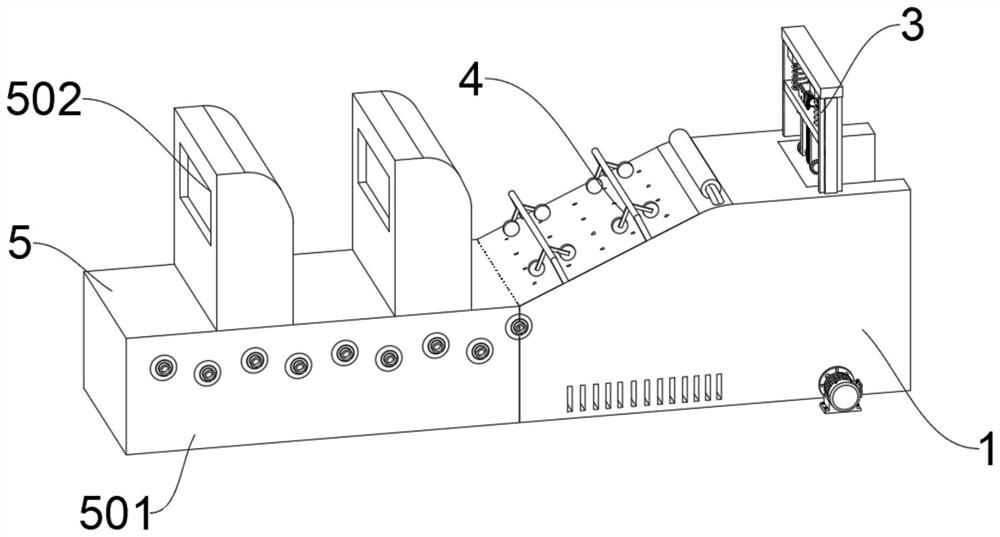

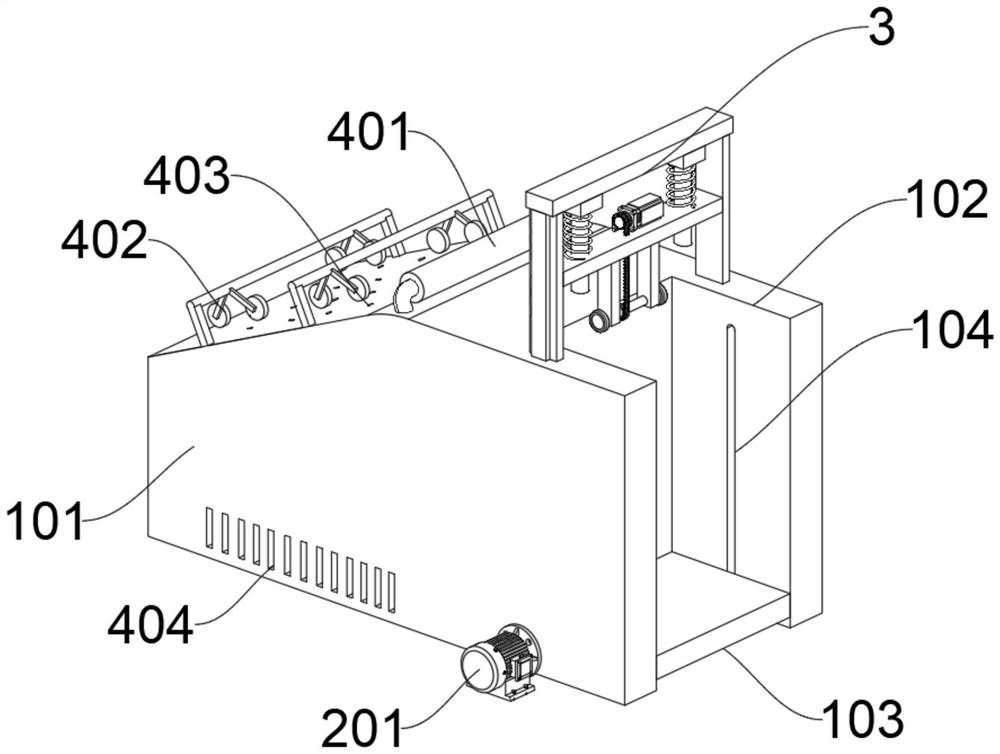

[0031] Please refer to Figure 1-4, a new printing machine for Chinese literature books, including a paper transfer device 1 and a printing device 5, a control device 2 is installed inside the paper transfer device 1, and a power device 3 is connected to the top of the paper transfer device 1, The rear end of the power device 3 is provided with an anti-stacking device 4 , and the printing device 5 is located behind the paper transfer device 1 .

[0032] The paper transfer device 1 includes a housing 101, the front end of the housing 101 is provided with a white paper storage place 102, the inner side of the white paper storage place 102 is provided with a moving groove 104, and the inside of the white paper storage place 102 is fitted with a lifting plate 103.

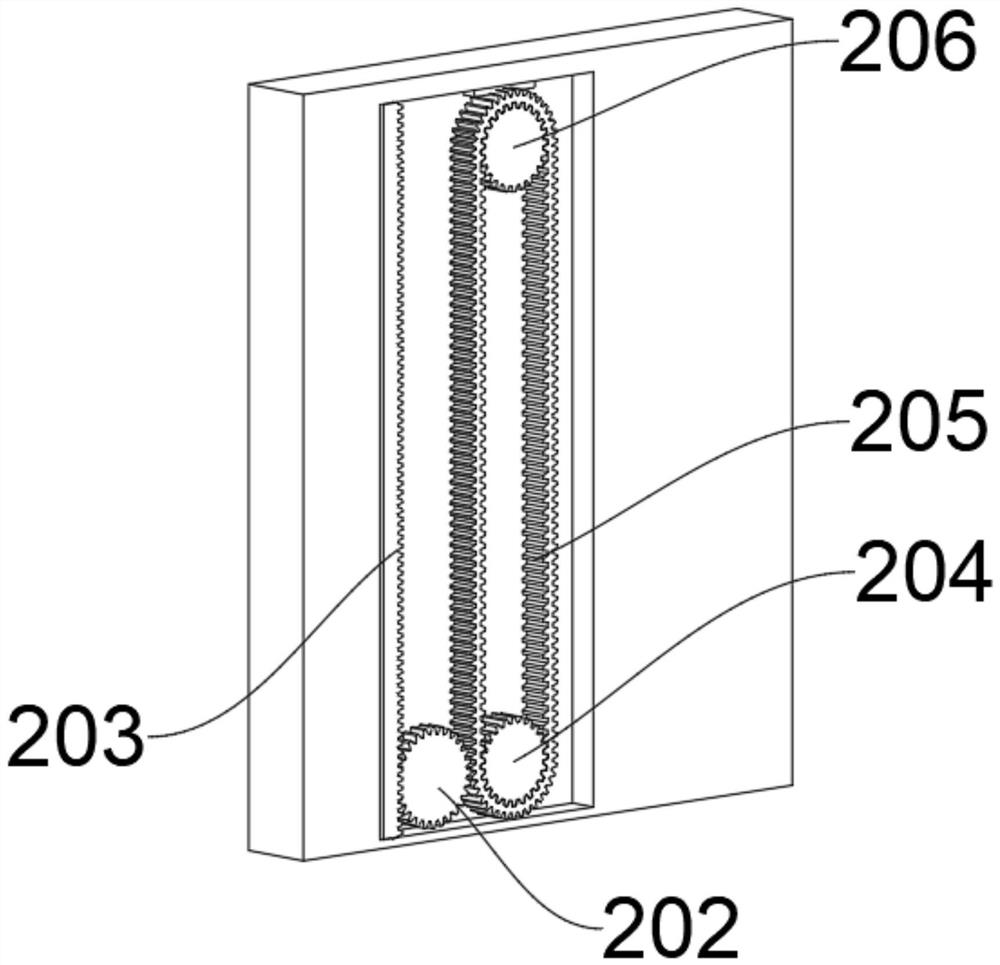

[0033] The control device 2 includes an electric motor 201, two electric motors 201 are provided, and the two electric motors 201 are respectively threaded on the outer sides of the two ends of the white paper depository...

Embodiment 2

[0037] Please refer to Figure 2. The difference in the basis of Embodiment 1 is that the anti-stacking device 4 includes a guide wheel 401 and a paper transfer wheel B402. Behind the wheel 401, the top of the housing 101 is provided with a plurality of adsorption holes 403, and the adsorption holes 403 are located below the paper transfer wheel B402, and the two sides of the housing 101 are provided with air outlets 404, and the inside of the housing 101 is connected with a blower. The air inlet is connected to the adsorption hole 403 , and the air outlet of the blower is connected to the air outlet 404 .

[0038] The anti-stacking device 4 of the present invention can separate two stacked papers, and then transport them to the printing device 5 respectively. The anti-stacking device 4 includes a guide wheel 401 and a paper transfer wheel B402, and the guide wheel 401 is movably connected to the casing. 101, the paper transfer wheel B402 is located behind the guide wheel 401, ...

Embodiment 3

[0040] Please refer to Figures 5-6, the difference in the basis of Embodiments 1 and 2 is that the printing device 5 includes a base 501, the base 501 is located at the rear of the housing 101, and an inking device 502 is connected above the base 501, and the base 501 The interior of the paper transfer roller 503 is connected with several paper transfer rollers 503, the surface of the paper transfer roller 503 is provided with an air inlet 506, the inside of the paper transfer roller 503 is hollow and connected with an inner cylinder 507, one end of the paper transfer roller 503 is fixedly connected with a rotating shaft 504, The other end of the paper roller 503 is fixedly connected with a hollow shaft 505 , an air pipe 508 is inserted into one end of the inner cylinder 507 , and the air pipe 508 is located inside the hollow shaft 505 , and an air inlet slot 509 is opened outside the inner cylinder 507 .

[0041] The present invention utilizes the paper transfer roller 503 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com