Cutting device for glass fiber yarn production

A cutting device and glass fiber yarn technology, applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems affecting the use of glass fiber yarn, slow cutting speed, and skewed cutting, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

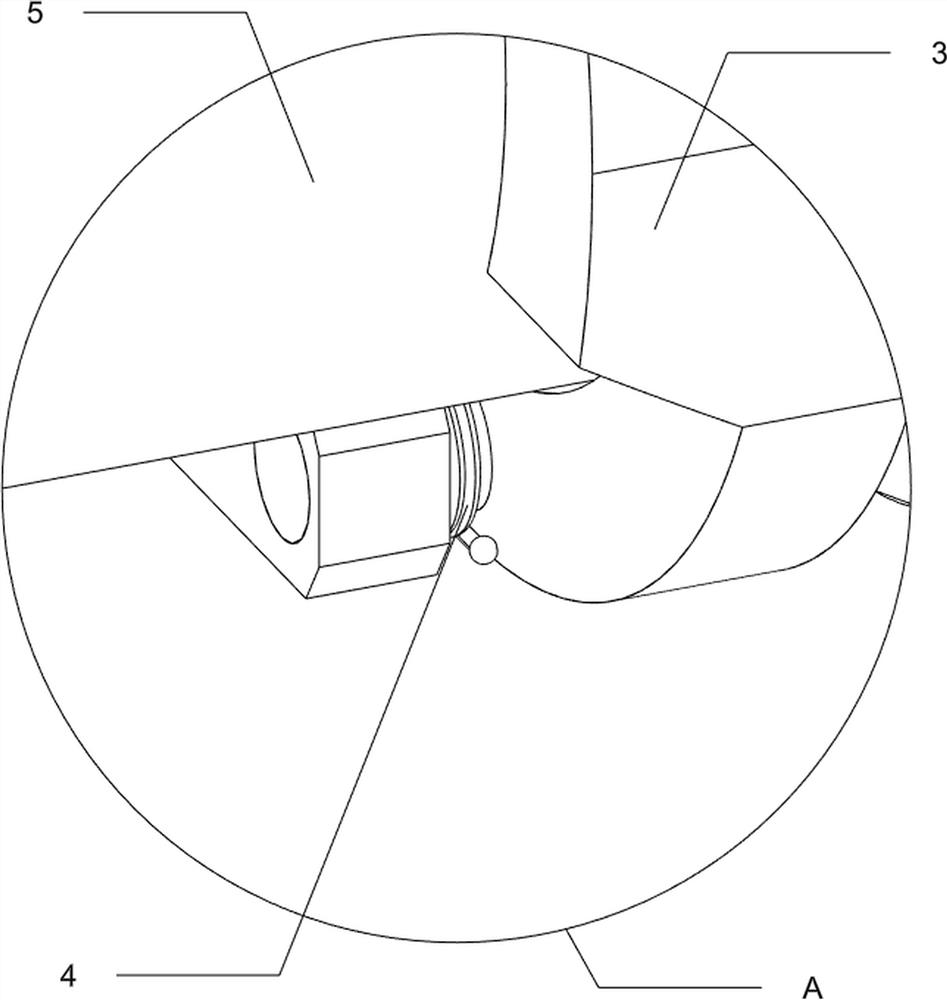

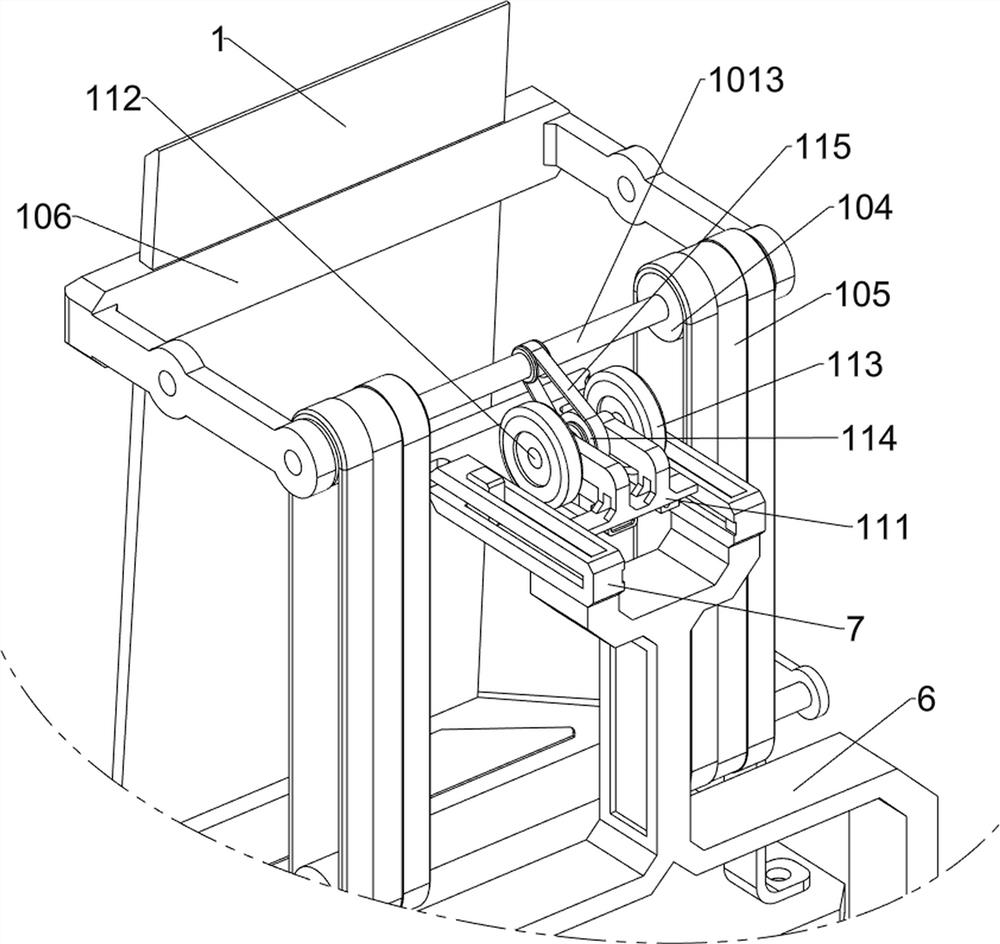

[0040] A cutting device for glass fiber yarn production, such as Figure 1-8As shown, it includes a base plate 1, a first connecting rod 2, a splint 3, a torsion spring 4, a discharge rod 5, a connecting frame 6, a guide rail 7, a cutter 8, a handle 9, a conveying mechanism 10 and a rotating mechanism 11, and the base plate 1 An anti-slip mat is installed at the bottom, which has an anti-slip effect. Two first connecting rods 2 are installed symmetrically on the upper part of the bottom plate 1. A discharge rod 5 is placed between the two first connecting rods 2. The discharge rod 5 is used to place Glass fiber yarn, the front side of the first connecting rod 2 is rotationally connected with a splint 3, the splint 3 is used to clamp the discharge rod 5, two torsion springs 4 are connected between the splint 3 and the first connecting rod 2, and the two torsion springs The spring 4 is left and right symmetrical, and the connecting frame 6 is installed on the front side of the b...

Embodiment 2

[0045] On the basis of Example 1, such as figure 1 , Figure 9 and Figure 10 As shown, a cutting mechanism 12 is also included, and the cutting mechanism 12 is used to drive the cutter 8, so that the cutter 8 can automatically cut the glass fiber yarn. The cutting mechanism 12 includes a rodless cylinder 121, a support rod 122 and a stabilizing plate 123 , a support rod 122 is installed on the rear side of the upper part of the connecting frame 6, a rodless cylinder 121 is connected between the top of the supporting rod 122 and the top of the connecting frame 6, and the rodless cylinder 121 is slidingly connected with the cutter 8, and the rodless cylinder 121 is used for driving Cutter 8, base plate 1 upper rear side is equipped with stabilizing plate 123, and stabilizing plate 123 is used for stabilizing glass fiber yarn, and stabilizing plate 123 is positioned at fixed rod 106 below.

[0046] Such as figure 1 , Figure 11 , Figure 12 and Figure 13 As shown, a stabi...

Embodiment 3

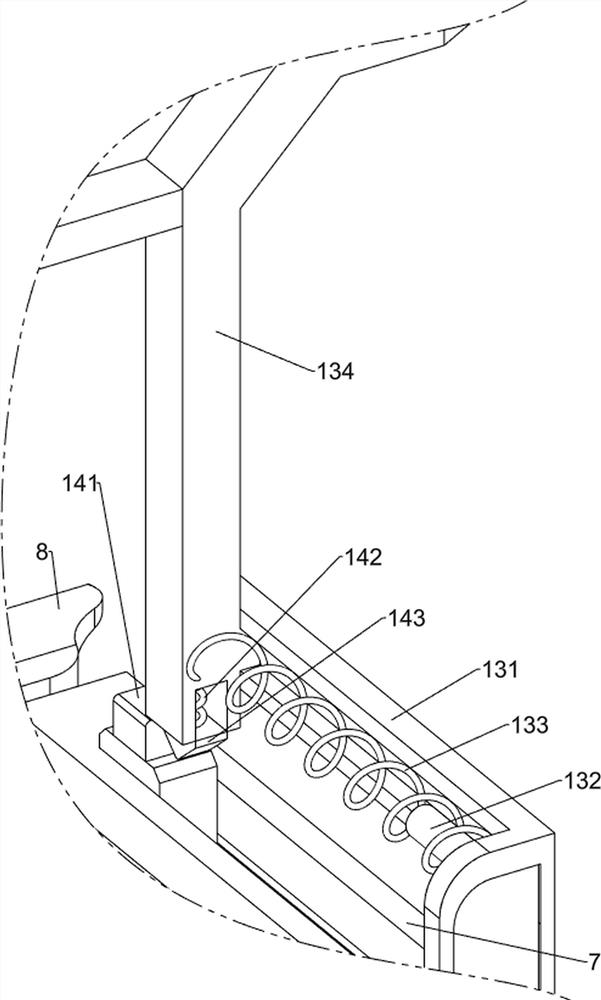

[0049] On the basis of Example 2, such as Figure 13 and Figure 14 Shown, also comprise push away mechanism 14, push away mechanism 14 is used for pushing away stabilizing mechanism 13, push away mechanism 14 includes second fixed block 141, the 4th spring 142 and wedge block 143, cutter 8 top left and right two sides Both sides are equipped with a second fixed block 141, the left and right sides of the bottom of the second connecting rod 134 are slidingly connected with wedge blocks 143, and the wedge block 143 cooperates with the second fixed block 141. A fourth spring 142 is connected, the top end of the fourth spring 142 is connected with the second connecting rod 134 , and the bottom end of the fourth spring 142 is connected with the wedge block 143 .

[0050] When the cutter 8 moves forward and resets, it will drive the second fixed block 141 to move forward, and the second fixed block 141 will move forward to drive the wedge-shaped block 143 to move forward, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com