Novel horizontal ditching method for deep open pit mine

An open-pit mine and horizontal technology, which is applied in the mining of open-pit mines, earthwork drilling, special mining, etc., can solve the problems of high construction requirements and large harmful effects of blasting, and achieves low blasting vibration speed, low waste hole rate, and harmful effects. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

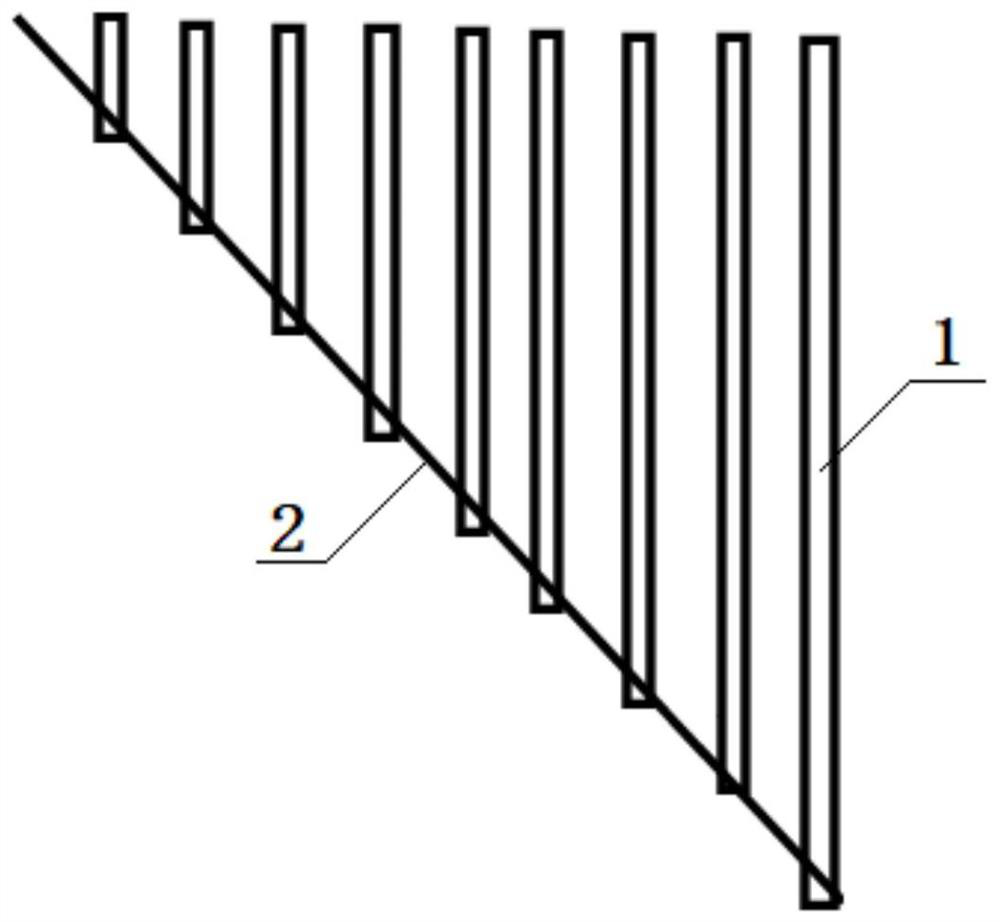

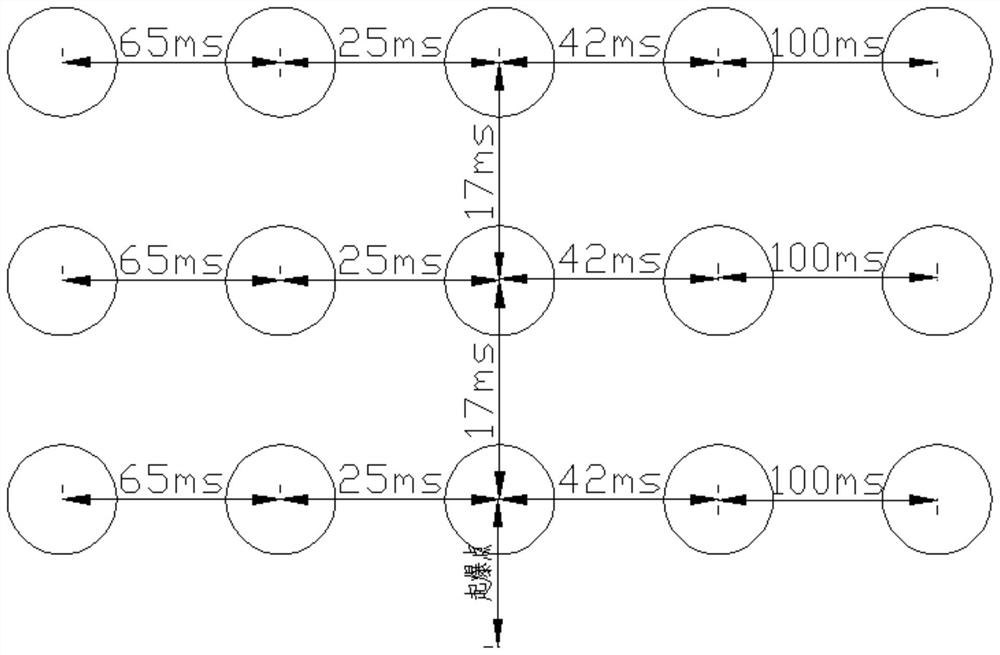

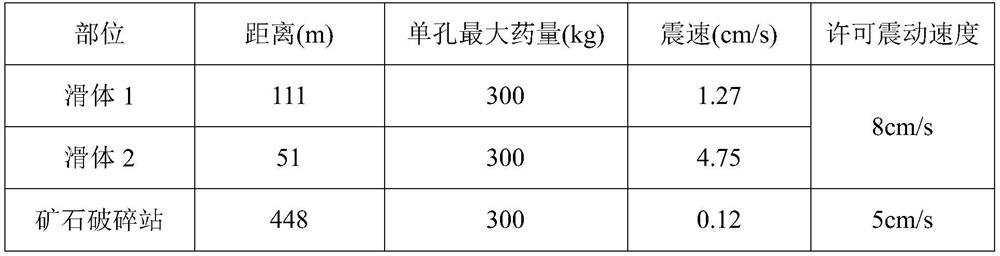

[0017] The new horizontal ditching method of the deep concave open-pit mine of the present invention is used for the new horizontal ditching of the deep concave open-pit mine, comprising the following steps:

[0018] S1. Carry out full-section high middle cutting blasting in the clear area at the bottom of the stope to form a free surface for subsequent trenching operations; after blasting, dig out the clear area and perform drainage.

[0019] For the new horizontal ditching of deep concave open-pit mines, the problem of drainage must first be considered, so the first blasting of ditching adopts the traditional full-section high middle cut blasting to create a free surface for subsequent ditching operations. The opening of the horizontal roadway is preferably located in the blasting area. After the blasting, the clear part should be dug out as soon as possible so that the water can be drained through the horizontal roadway. In addition, mechanical drainage can also be assisted....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com