Sliding type anti-pinch escalator

An anti-pinch escalator and sliding technology, which is applied in escalators, transportation and packaging, etc., can solve the problems of foreign matter entering the apron and steps, trigger insensitivity, safety accidents, etc., to avoid injury, reset easily, and trigger sensitively Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

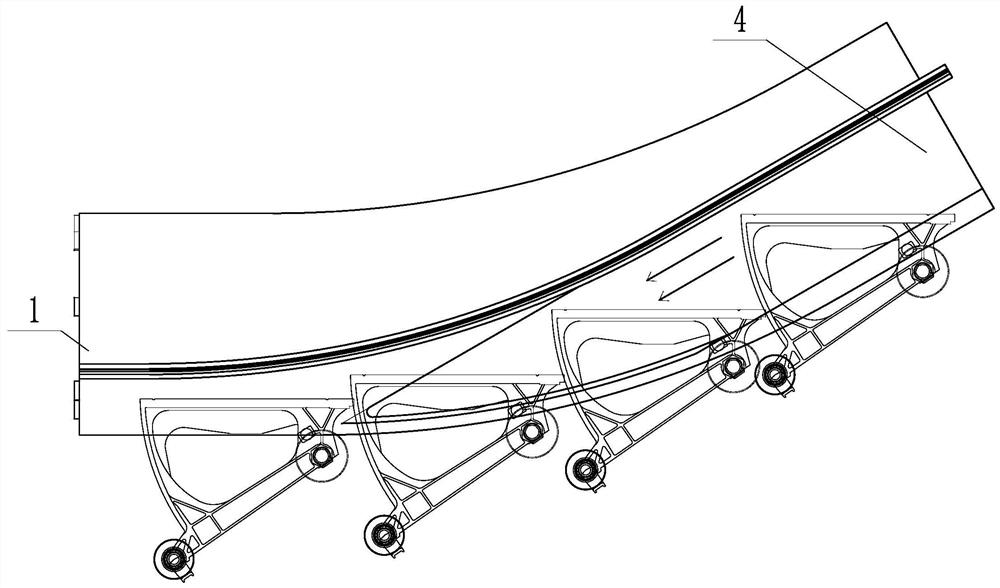

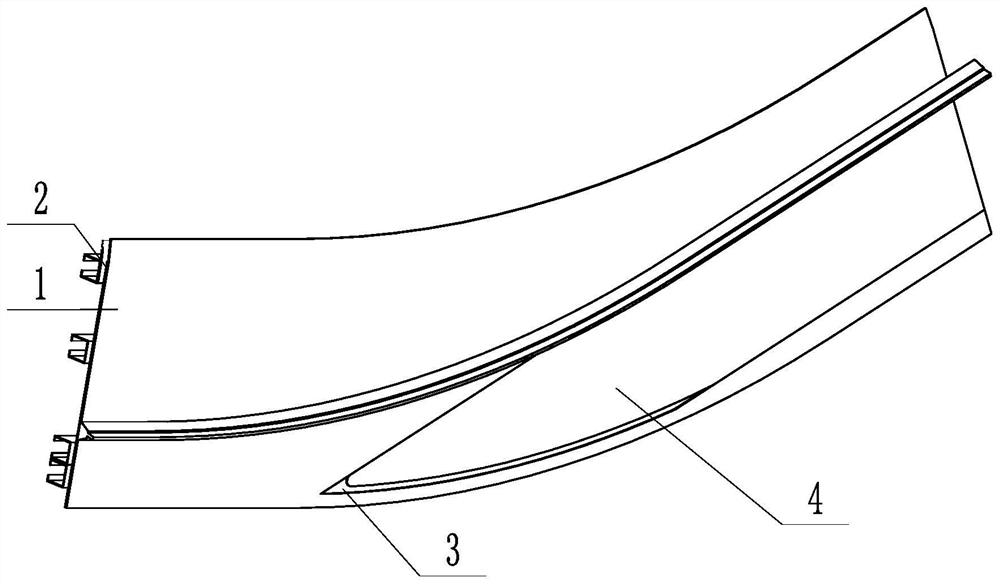

[0035] A sliding anti-pinch escalator, such as Figures 1 to 3 As shown, the apron plate of the escalator includes an apron outer plate 1 close to the steps and an apron support plate 2 away from the steps. The apron outer plate 1 is provided with a sliding notch 3, and the sliding notch 3 is provided with an anti-splitting plate 4, and the apron The support plate 2 is provided with a guide groove 5 corresponding to the anti-splitting plate 4 , and the anti-splitting plate 4 is slidably connected to the apron support plate 2 through the guide groove 5 .

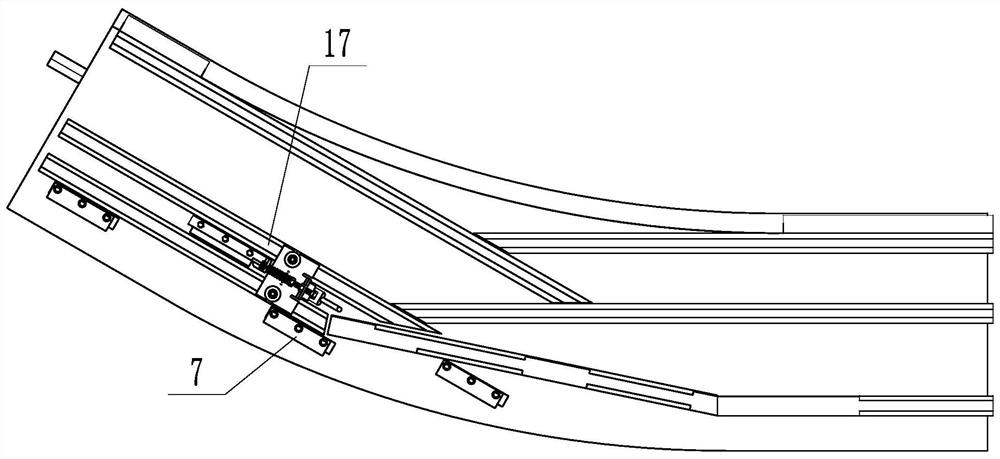

[0036] Such as Figure 4As shown, the side of the anti-splitting plate 4 close to the apron support plate 2 is fixedly connected with several clips 7, the clips 7 extend into the guide groove 5, and the clips 7 protrude toward the apron support plate 2. There is a gap between the apron support plate 2. The structure realizes how the anti-clamping plate 4 is slidably connected to the apron support plate 2 . After it is put ...

Embodiment 2

[0040] The difference technical feature of present embodiment and embodiment 1 is:

[0041] Such as Figure 8 , 9 As shown, the side of the apron support plate 2 facing the anti-splitting plate 4 and the side of the anti-splitting plate 4 facing the apron support plate 2 are all provided with corresponding air flow channels 19, and the air flow channels 19 match to form air holes 20, and the apron support plate 2 also has A blower is provided, and the blower ventilates in the air hole 20, and the end of the air flow channel 19 is provided with a blocking block 21. When the anti-splitting plate 4 slides, the blocking block 21 on the anti-splitting plate 4 and the apron support plate 2 merges to block the air hole 20 , the airflow blown by the blower passes between the anti-splitting plate 4 and the apron support plate 2 and reduces the friction between the two plates.

[0042] The structure plays a role of reducing friction. When foreign matter invades, an external force is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com