Construction method for integral hoisting of roof primary and secondary structure assembly units

A technology of assembling units and overall hoisting, which is applied in the direction of building construction and construction, which can solve the problems of high safety risks and low efficiency of manual installation at high altitudes, and achieve the effects of stable installation, favorable inspection and acceptance, and quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The construction method for the overall hoisting of the roof primary and secondary structure assembly units includes the following steps in sequence:

[0033] S1. According to the site plan, hoist the installation area in blocks and sections, select the supporting parts between columns to install the overall hoisting unit, and then bulk install and connect parts in blocks at high altitude;

[0034] Divide the roof into multiple installation units according to the drawings and the actual situation on site. On the flat ground in the installation unit area, place the two steel beams that belong to the supporting parts between adjacent columns in the same span, adjust the distance between the two steel beams, and control the two ends of the two steel beams to be even, so as to ensure the Component installation accuracy.

[0035] S2. A plurality of purlins are connected and installed between two steel beams on the ground. Multiple purlin struts, multiple purlin diagonal br...

Embodiment 2

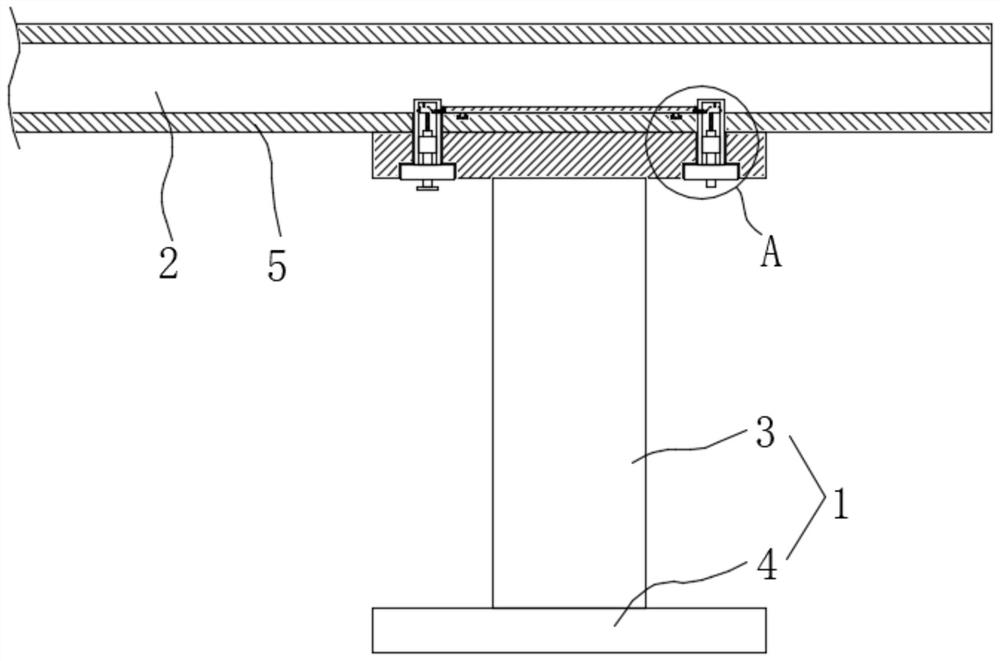

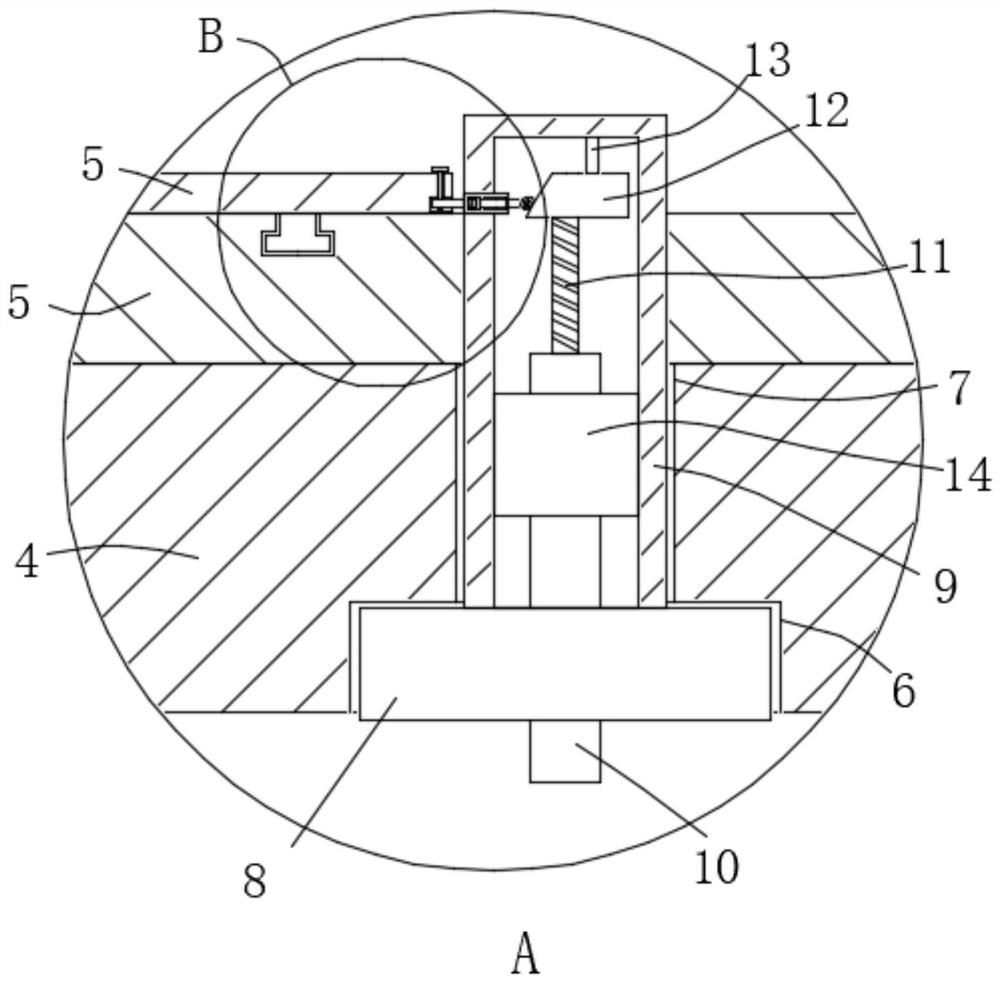

[0041] Please combine Figure 2 to Figure 4 The difference between Embodiment 2 and Embodiment 1 is that each purlin 4 is connected and fixed on the corresponding steel beam 1 through a locking assembly, which not only makes the connection between steel beam 1 and purlin 4 more stable and reliable, but also facilitates Disassembly and assembly of purlin 4 on steel beam 1.

[0042]The steel beam 1 in this embodiment includes an upright web 2 and two flange plates 1-3 vertically fixed on the bottom and top of the web 2 respectively. The purlin 4 has a flange plate 2 5 , and realizes butt joint between the flange plate 2 5 at the bottom and the flange plate 1 3 at the top of the web 2 .

[0043] The locking assembly includes an outer cylinder 9 inserted on the top flange plate 3 of the steel beam 1 . In this embodiment, the cross-sections of the outer cylinder 9, the first through hole 7, and the second through hole can be in a quadrilateral structure, so as to realize the stab...

Embodiment 3

[0056] Embodiment 3 is an economical comparison between the construction method of overall hoisting of the roof primary and secondary structure assembly units in Embodiment 1 and the traditional installation method.

[0057] Using the traditional installation method, 2 people on the ground assemble a crane, and a group of 4 people lift it. One crane can lift 12 steel beams a day on average. However, the overall hoisting of the installation unit in Embodiment 1 is adopted, 4 people and 1 crane are assembled on the ground, and 2 cranes are hoisted in a group of 8 people. On average, the hoisting of 6 groups of units can be completed in one day. 6 groups of units are 12 steel beams and systems. Secondary components such as rods, purlins, braces, corner braces, etc. The traditional installation method also requires a crane to hoist the secondary components to the roof, 2 people to disperse the purlins, 2 people to install the purlins, a group of 4 people to install the braces, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com