Method for diagnosing and repairing low-temperature unfrozen defect caused by soft and hard interface freezing pipe fracture

A repair method, a technology of freezing pipes, which is applied in the field of low-temperature unfrozen defect detection, which can solve the problems of low-temperature unfrozen defects that are difficult to quickly and accurately repair, the temperature at the fracture site of the frozen pipe fracture cannot be accurately monitored, and the pressure of leaked brine seeping into soft-hard composite formations is difficult to monitor And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

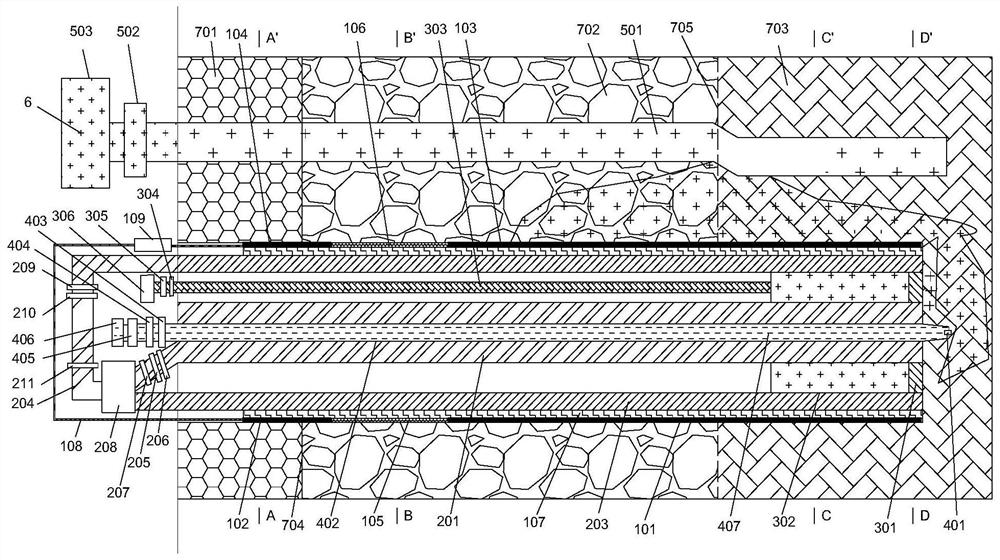

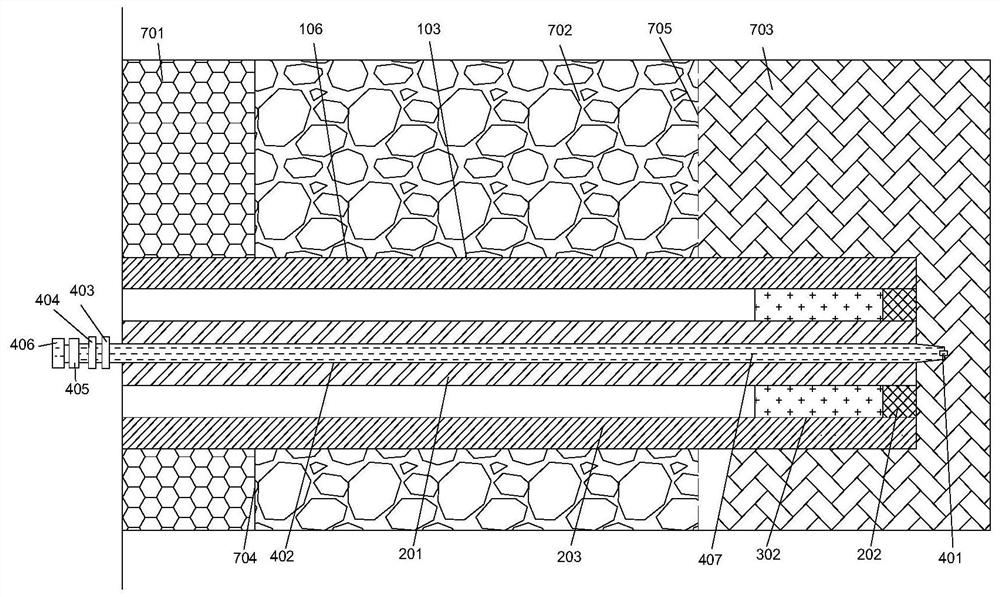

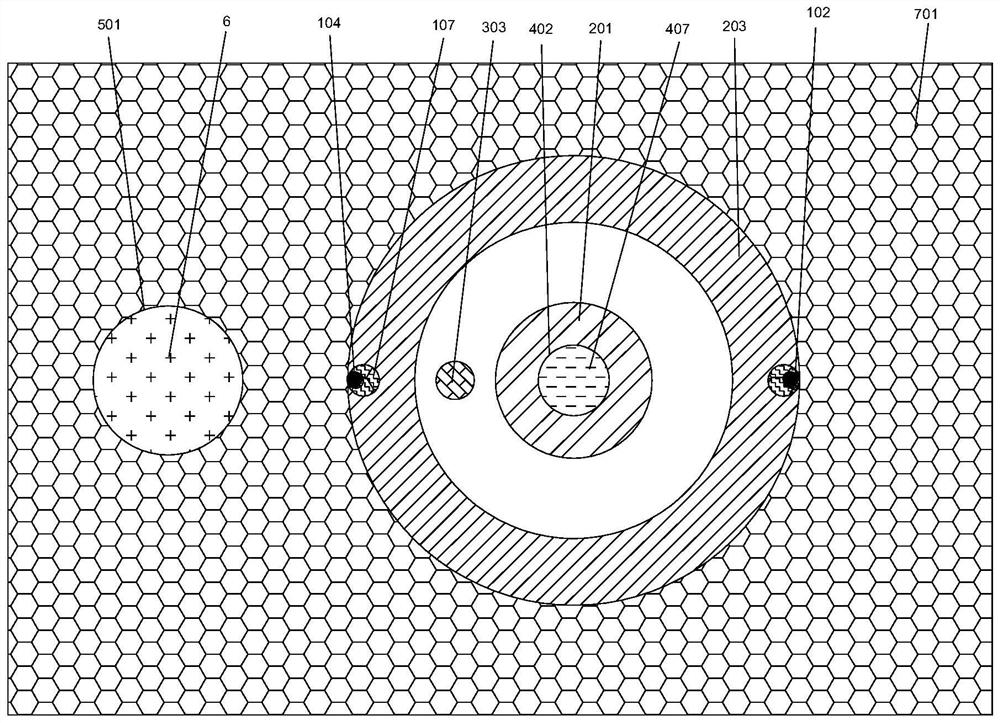

[0056] Diagnose the low-temperature unfrozen defects caused by the fracture of the frozen pipe at the soft-hard interface and repair devices, including: fiber grating temperature measurement system, dynamic water drainage and seepage pressure detection system, permafrost gap volume detection system, and repair freezing system.

[0057] like figure 1 The above-mentioned systems shown schematically are used as devices, and the above-mentioned systems should be installed and integrated in a hard protective case in practical application.

[0058] The first part of the subsystem: fiber grating temperature measurement system

[0059] As an example, figure 1 The medium fiber grating temperature measurement system includes a first optical fiber 101, a second optical fiber 102, a third optical fiber 103, a fourth optical fiber 104, a first grating 105, a second grating 106, a fiber grating encapsulant 107, a fiber grating connecting line 108, an optical fiber Raster controller 109 . ...

Embodiment 2

[0081] Step 1, prefabrication stage

[0082] In the stratum interface of the excavated subway tunnel, each frozen pipe 501 of the frozen pipe system is arranged, and the stratum interface involves the concrete segment 701, the rock layer 702, the soft soil layer 703, the concrete segment-rock interface 704, and the rock-soft soil interface 705; Prefabricated fiber grating temperature measurement system, power water cleaning and drainage and seepage pressure detection system, and permafrost gap volume detection system under each freezing pipe 501 of the freezing pipe system;

[0083] Prefabricate and repair the freezing system under each freezing pipe 501 of the freezing pipe system;

[0084] Each freezing pipe of the freezing pipe system is prefabricated with a flow sensor 502 and a liquid storage separation tank 503;

[0085] Step 2, Probing Phase

[0086] 2.1 Run the first part of the subsystem: fiber grating temperature measurement system

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com