Copper piece feeding device

A technology for copper parts and clips is applied in the field of copper parts feeding devices, which can solve the problems of deviation in positioning, insufficient assembly and pressing, and low operation safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

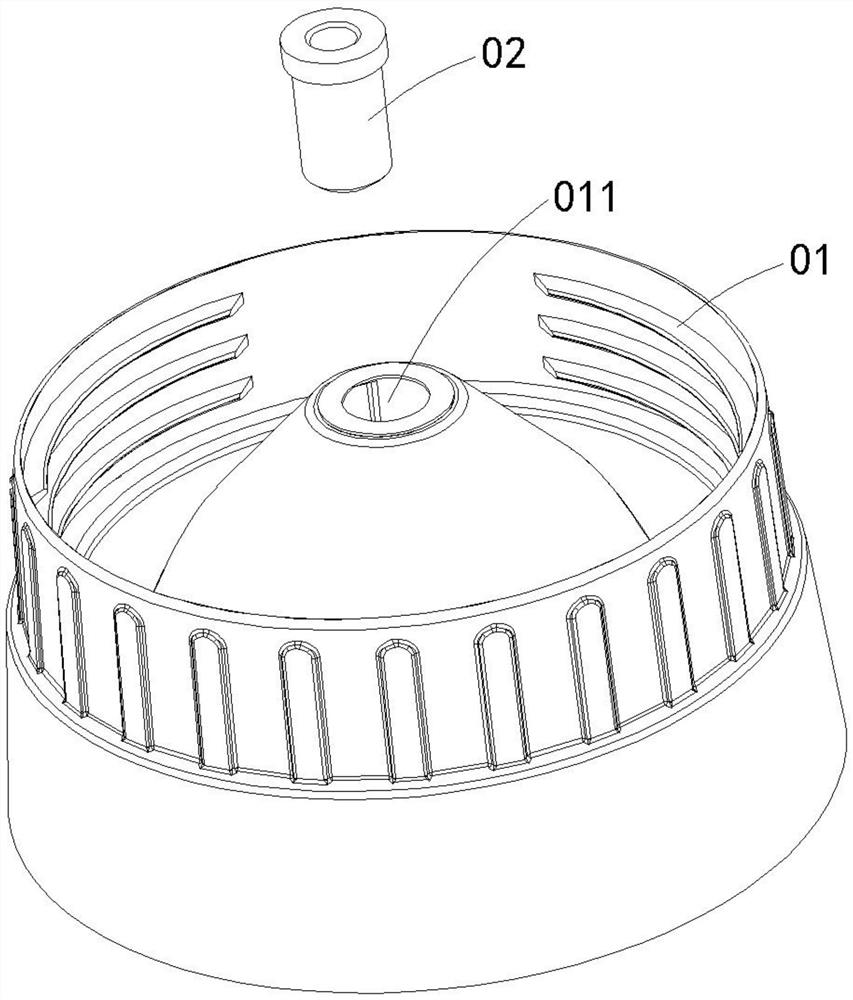

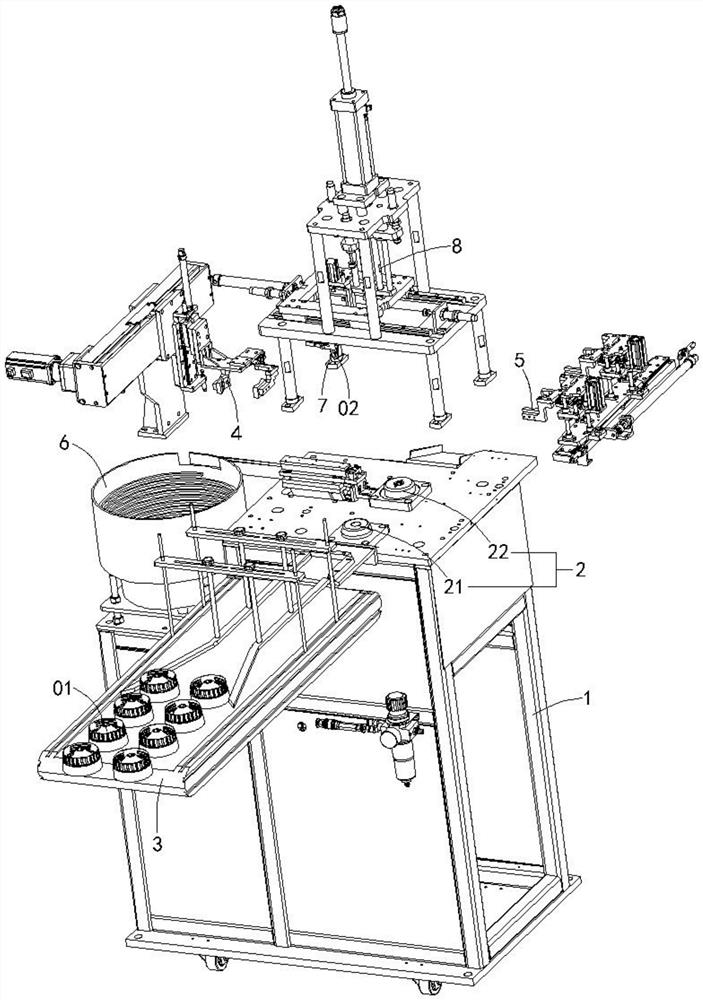

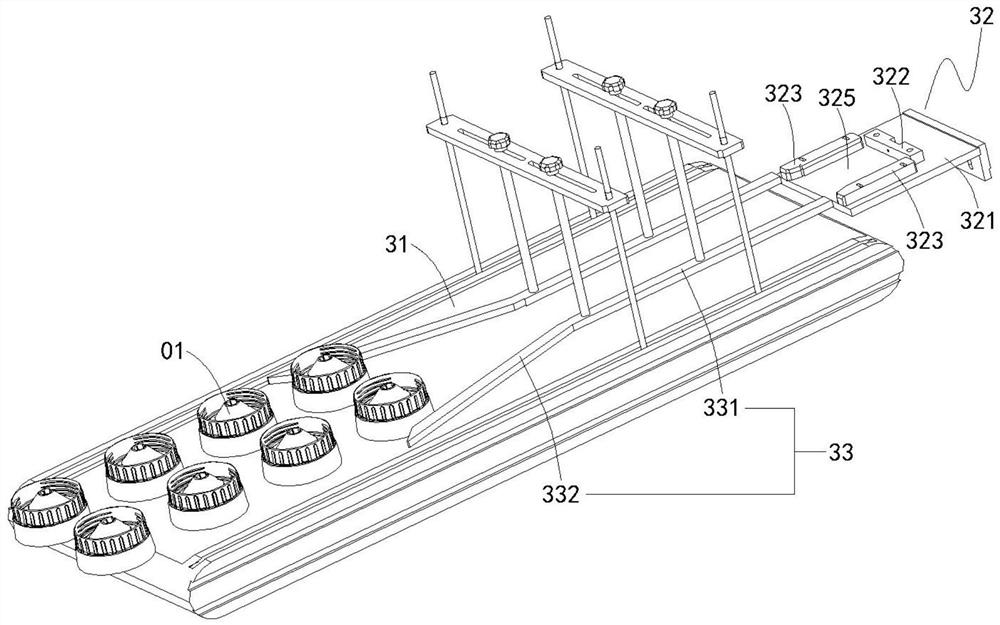

[0030] A kind of feeding device for copper parts, see figure 2, which includes a frame 1, a positioning mechanism 2, a first feeding mechanism 3, a first conveying mechanism 4, a second conveying mechanism 5, a second feeding mechanism 6, a third conveying mechanism 7, and a copper piece pressing mechanism 8. Wherein, the positioning mechanism 2 is used to position the base 01 so that the copper piece 02 is pressed into the base 01. The positioning mechanism 2 includes a first positioning block 21, a second positioning block 22, a first positioning block 21, and a second positioning block 22. All are arranged on the frame 1, the first positioning block 21 is used for positioning the base 01, and the second positioning block 22 is also used for positioning the base 01; it is movable on the middle position of the top surface of the second positioning block 22 There is a first positioning pin 23 protruding from the mounting hole 011 of the base 01 , the axis of the first positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com