Garbage can capable of automatically sealing cover and automatically popping up alarm based on garbage pressure

A technology of automatic pop-up and trash cans, which is applied in the direction of trash cans, garbage collection, household appliances, etc., can solve the problems of garbage accumulation, overfilling of trash cans, etc., and achieve the effect of saving time looking for empty trash cans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

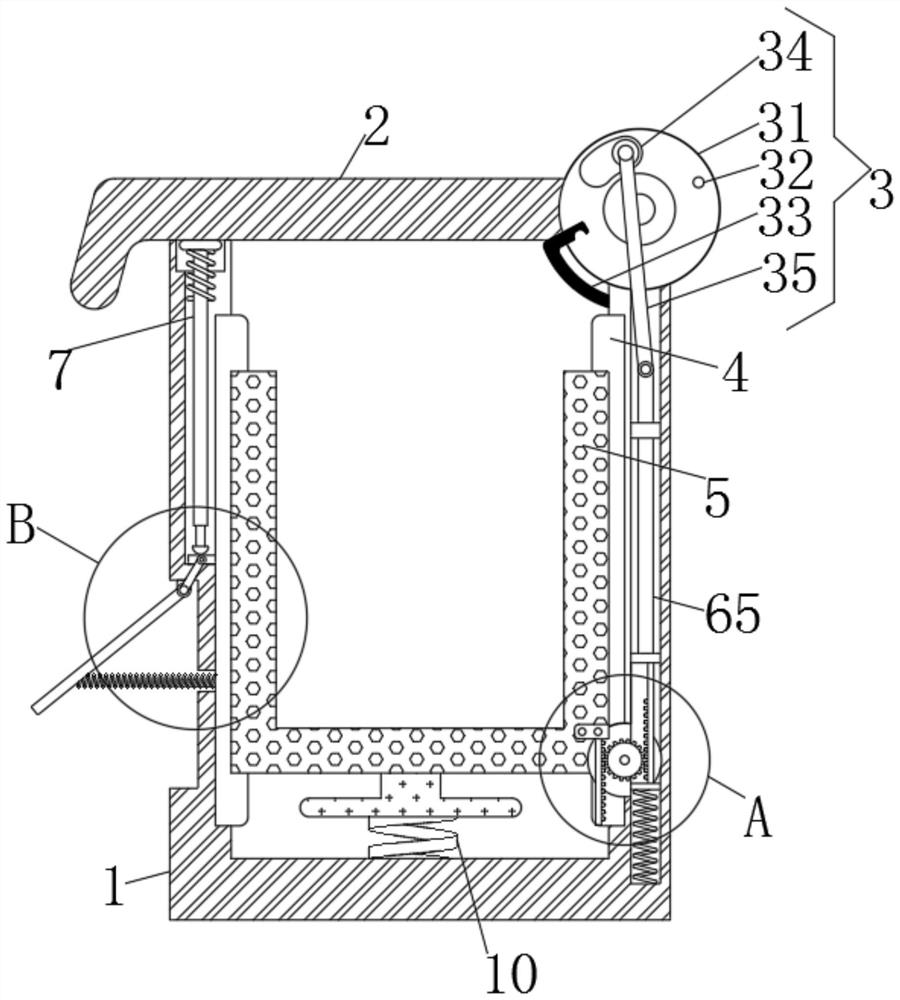

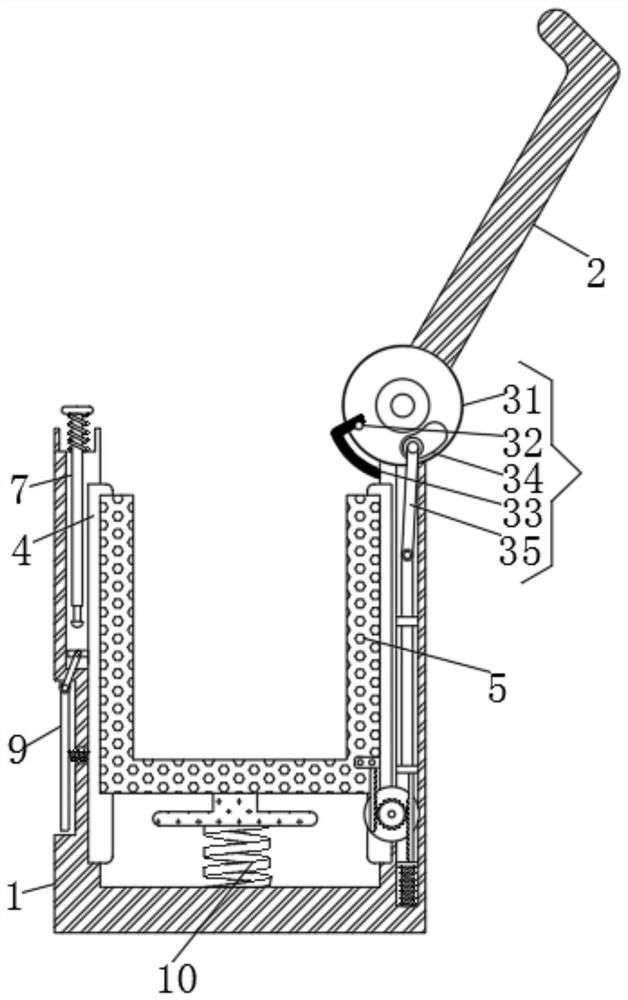

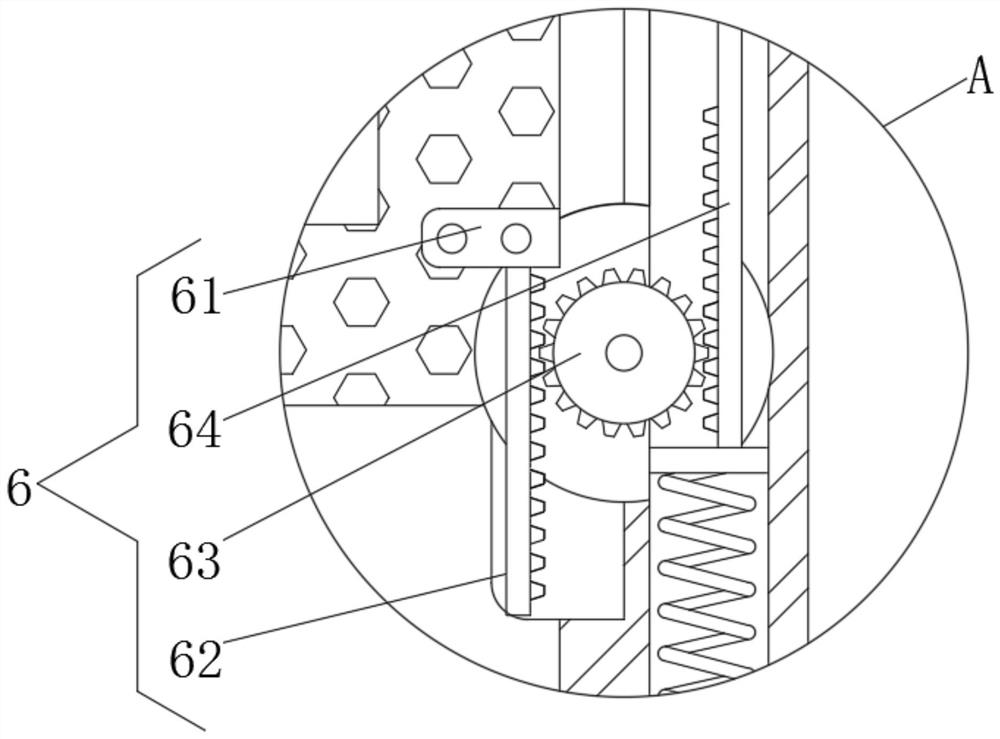

[0025] see Figure 1-3 , a garbage bin that automatically seals the lid based on garbage pressure and automatically pops up a warning, including an outer cylinder 1, a transmission device 3 is installed on the top of the outer cylinder 1, and the transmission device 3 includes a rotating shaft 31, a cylinder 32, a limit rod 33, Limiting groove 34, cylinder 32 is fixedly installed on the surface of rotating shaft 31, and limit rod 33 is fixedly installed on the periphery of rotating shaft 31, and the top of limit rod 33 is provided with semicircle groove, and the diameter of semicircle groove and the section diameter of cylinder 32 Matched, the surface of the rotating shaft 31 is provided with a limit groove 34, the left and right sides of the inner wall of the outer cylinder 1 are fixedly equipped with a slide rail 4, the outer periphery of the slide rail 4 is slidably connected with the inner cylinder 5, and the right side of the cover body 2 is connected with a Engagement de...

Embodiment 2

[0027] see figure 1 , 2 and 4, a garbage bin that automatically seals the lid based on garbage pressure and automatically pops up a warning, including an outer cylinder 1, a transmission device 3 is installed on the top of the outer cylinder 1, and the transmission device 3 includes a rotating shaft 31, a cylinder 32, and a limit rod 33, limit groove 34, cylinder 32 is fixedly installed on the surface of rotating shaft 31, limit bar 33 is fixedly installed on the periphery of rotating shaft 31, and the top of limit bar 33 is provided with semicircle groove, and the diameter of semicircle groove and the diameter of cylinder 32 The cross-section diameters are matched, the surface of the rotating shaft 31 is provided with a limit groove 34, the left and right sides of the inner wall of the outer cylinder 1 are fixedly installed with slide rails 4, and the outer periphery of the slide rails 4 is slidingly connected with the inner cylinder 5, and the bottom end of the inner cylinde...

Embodiment 3

[0029] see Figure 1-4 , a garbage bin that automatically seals the lid based on garbage pressure and automatically pops up a warning, including an outer cylinder 1, a transmission device 3 is installed on the top of the outer cylinder 1, and the transmission device 3 includes a rotating shaft 31, a cylinder 32, a limit rod 33, Limiting groove 34, cylinder 32 is fixedly installed on the surface of rotating shaft 31, and limit rod 33 is fixedly installed on the periphery of rotating shaft 31, and the top of limit rod 33 is provided with semicircle groove, and the diameter of semicircle groove and the section diameter of cylinder 32 Matched, the surface of the rotating shaft 31 is provided with a limit groove 34, the left and right sides of the inner wall of the outer cylinder 1 are fixedly equipped with slide rails 4, the periphery of the slide rail 4 is slidingly connected with the inner cylinder 5, and the bottom end of the inner cylinder 5 is connected by a thick spring. 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com