Knapsack type air atomizing sprayer

An air atomization and sprayer technology, which is applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of narrow use range, low use efficiency, waste of liquid medicine, etc., achieve good atomization effect, good use effect, and reduce labor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

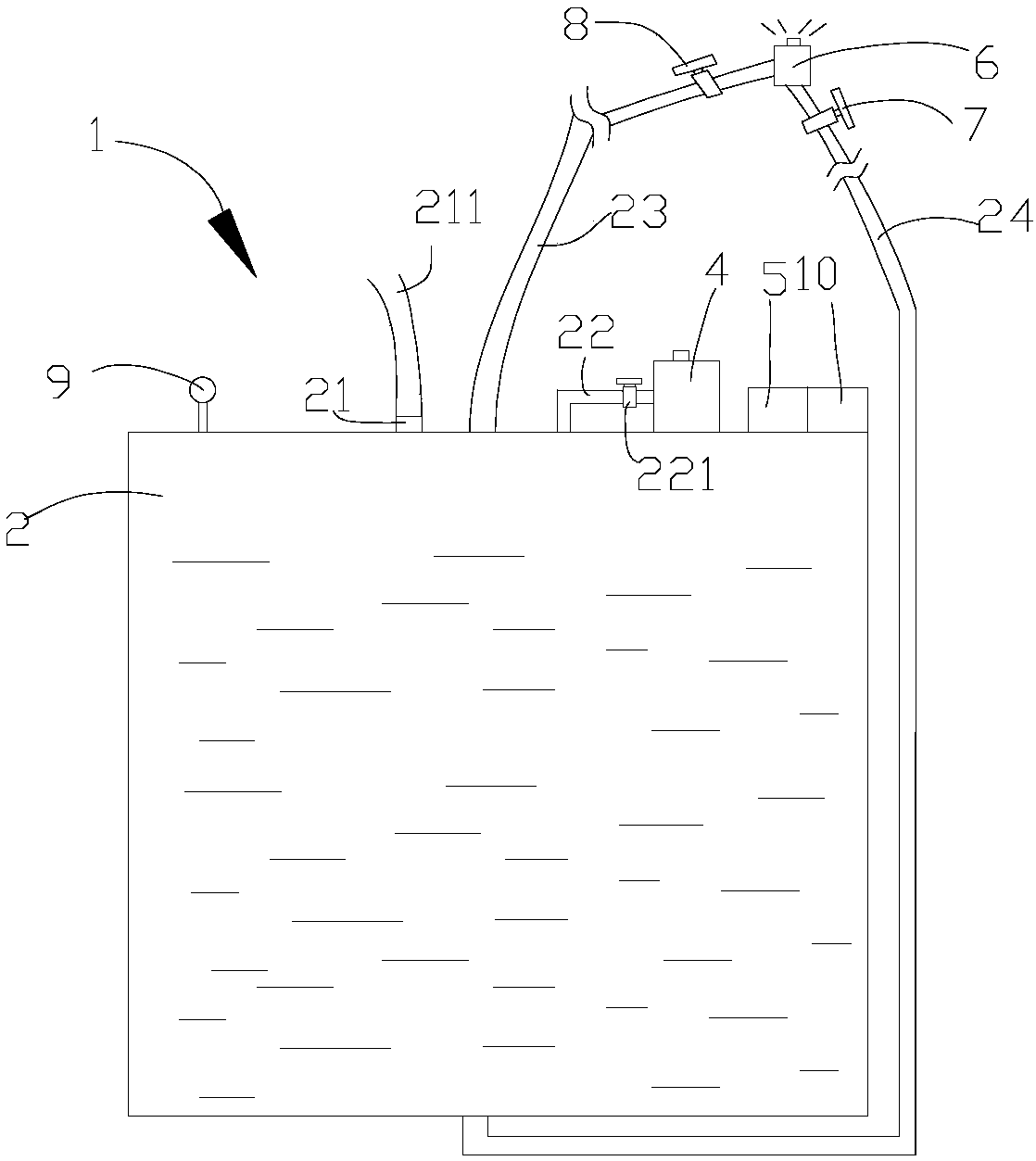

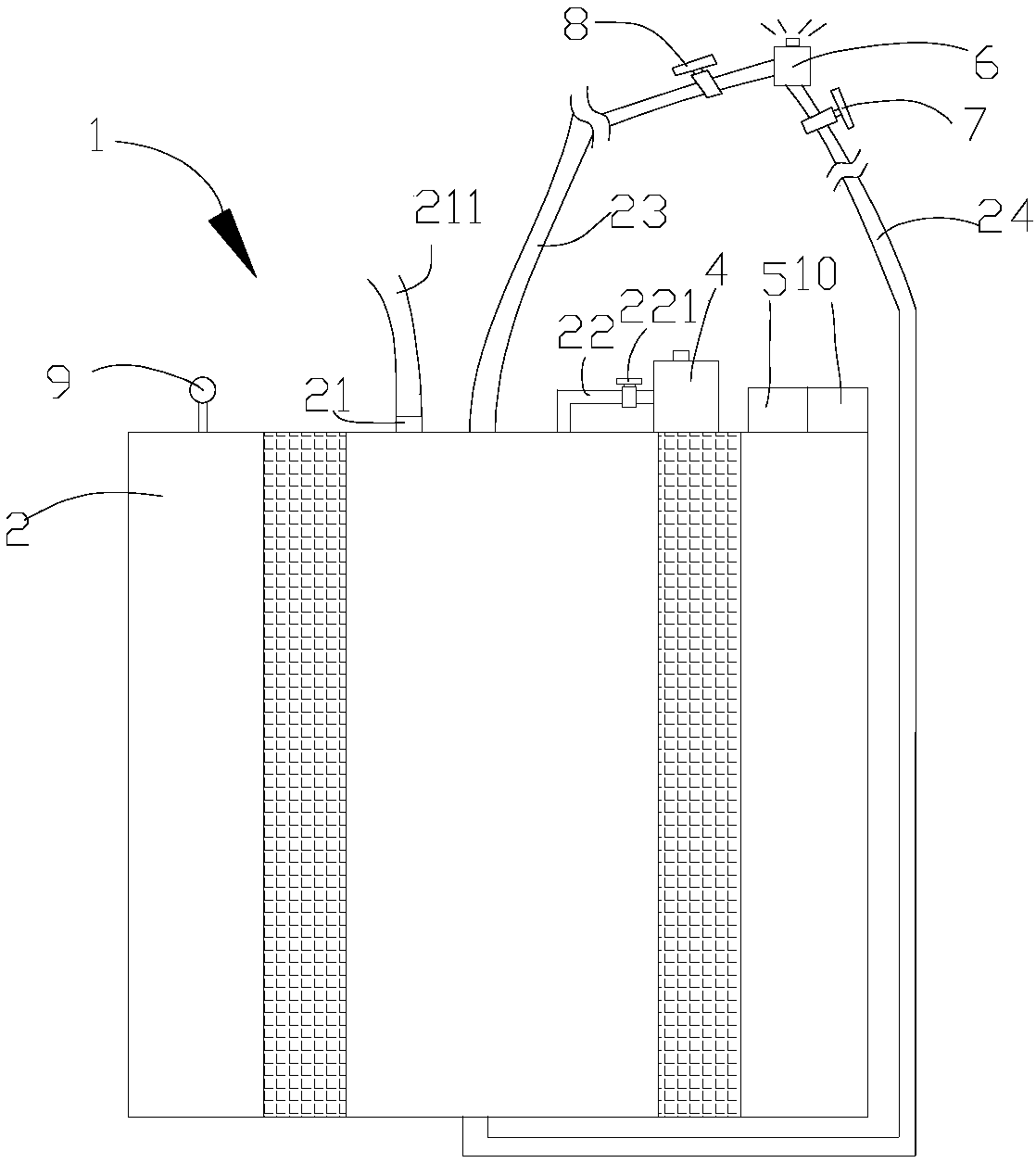

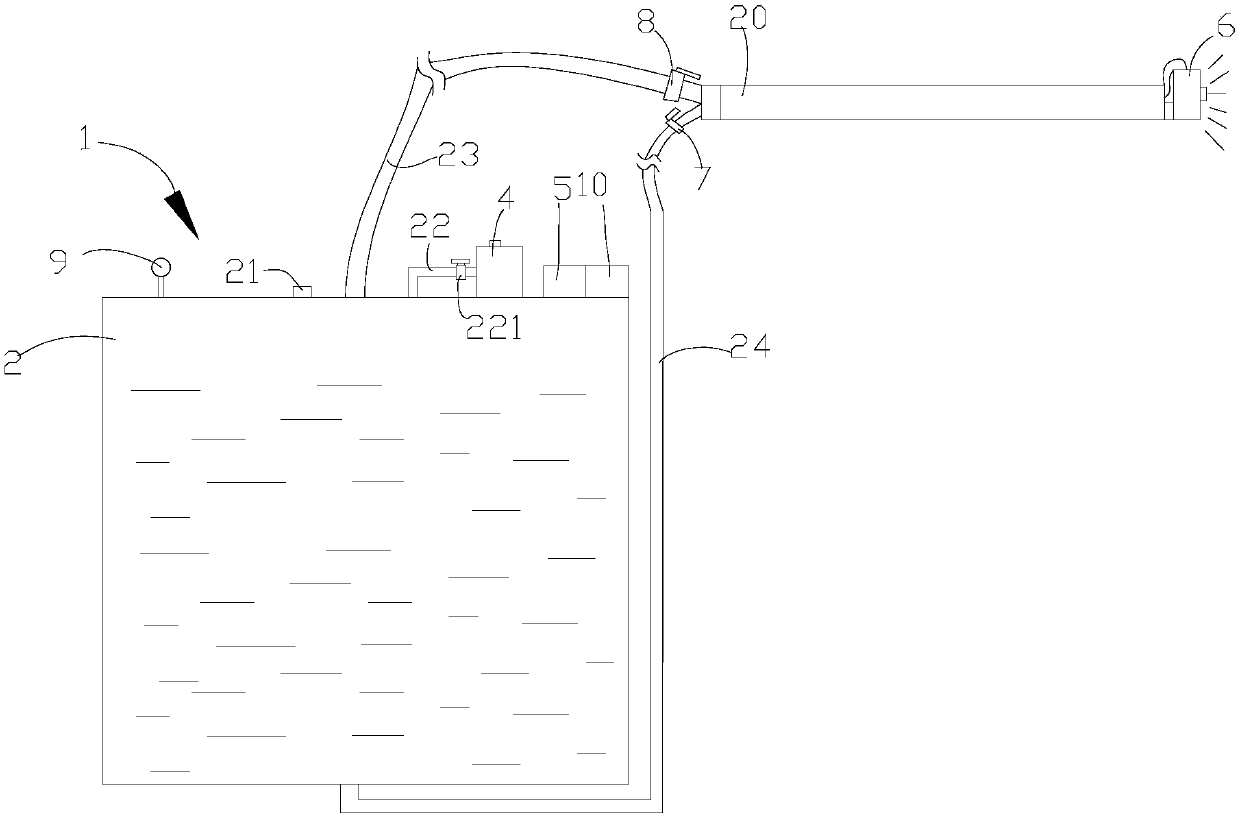

[0028] see figure 1 and figure 2 , in a preferred embodiment of the present invention, a knapsack air atomization sprayer 1 includes an air-liquid tank 2, a shoulder strap 3, an air source device 4, a power unit 5 and an air-liquid atomization nozzle 6. A double-shoulder strap 3 is installed on the rear side of the gas-liquid tank 2, which is convenient for the operator to carry the sprayer 1 on his back. The upper part of the gas-liquid tank 2 is provided with a liquid inlet 21 for introducing liquid medicine into the gas-liquid tank 2, and the liquid inlet 21 is provided with a sealing cover or a sealing plug for sealing the liquid inlet 21. When the operator removes the sealing cover or the sealing plug from the liquid inlet 21, the external medicinal liquid can be introduced into the gas-liquid tank 2 through the liquid inlet 21. After the introduction is completed, the The sealing cover or the sealing plug seals the liquid inlet 21, that is, the work of adding liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com