Processing method for sealing gasket of vacuum arc extinguishing cylinder of high-voltage circuit breaker of intelligent power grid

A high-voltage circuit breaker and vacuum arc extinguishing technology, which is used in high-voltage air circuit breakers, circuits, high-voltage/high-current switches, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

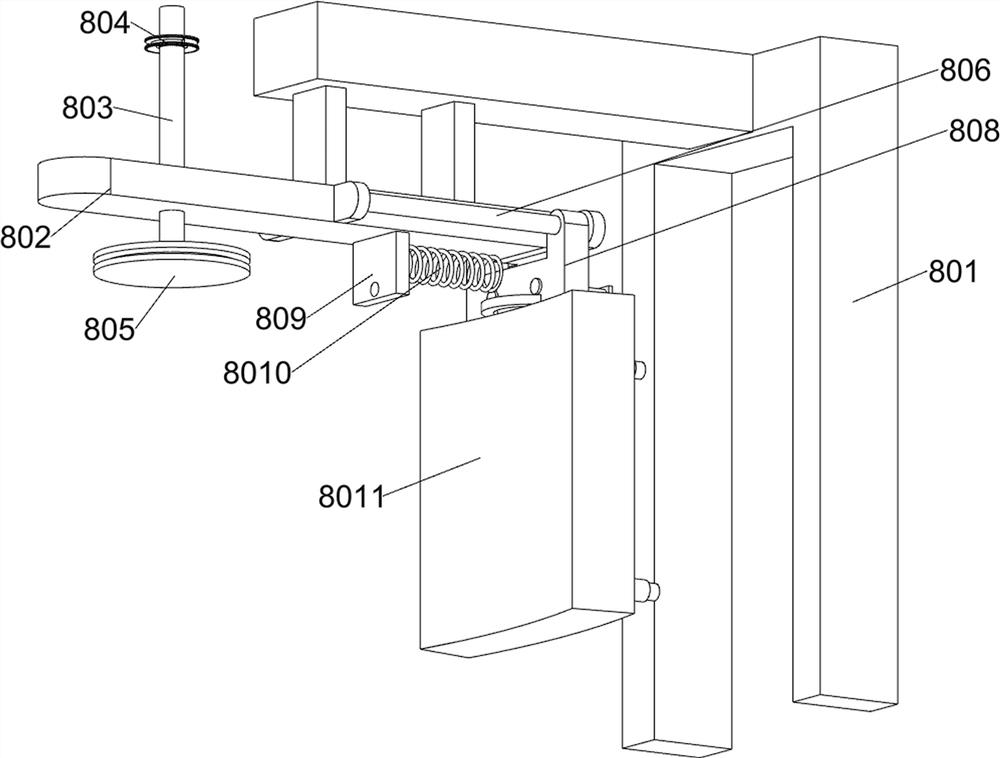

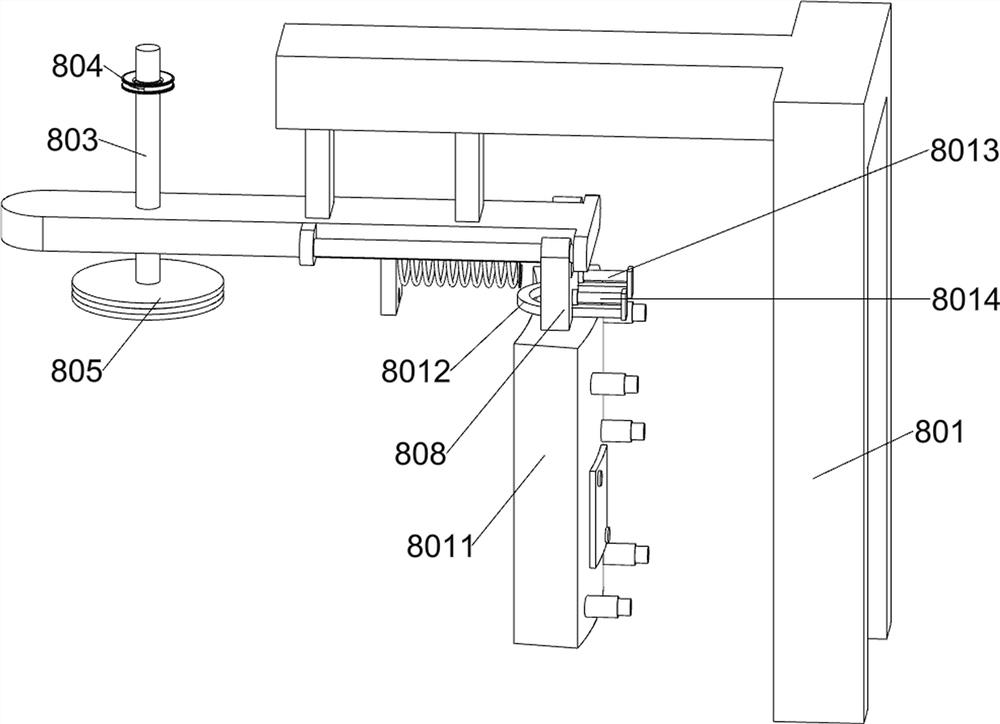

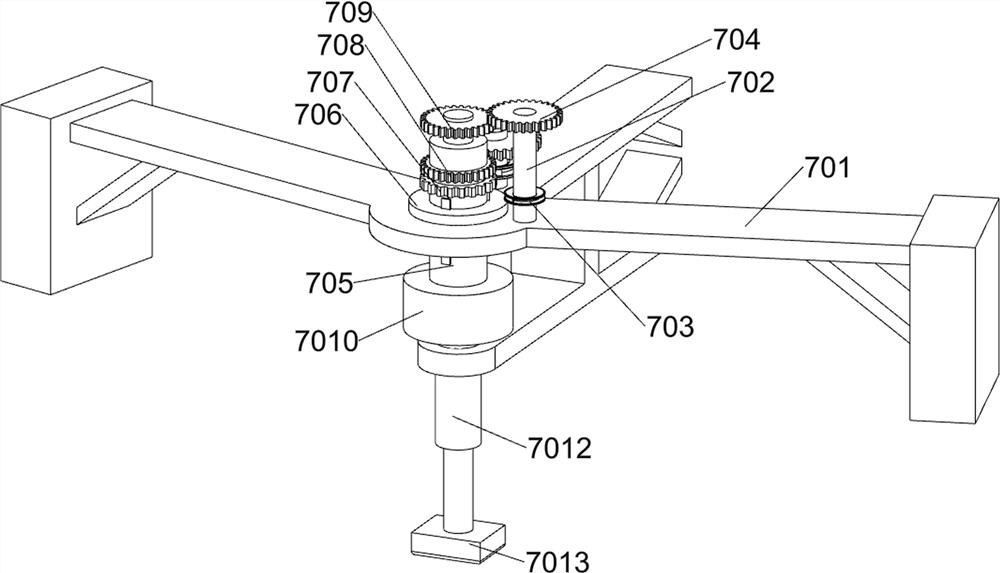

[0034] A method for processing the vacuum interrupter gasket of a smart grid high-voltage circuit breaker, such as figure 1 As shown, the processing method for the vacuum interrupter gasket of the smart grid high-voltage circuit breaker adopts the following processing equipment. Plate 5, tilting and flattening system 6, pressing down and rotating system 7 at the same speed, differential convex system 8, first mounting seat 10 and operation control panel 11; the lower part of the working machine plate 1 is welded with the supporting foot column 2; the working The top of the machine tool board 1 is installed with a notch discharge barrel 3; the top of the working machine board 1 is welded with the installation support column 4; the top of the installation support column 4 is welded with the installation middle plate 5; the bottom of the installation middle plate 5 is installed with a tilting and flattening system 6. The tilting and flattening system 6 is connected with the downw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com