Autonomous ventilation and heat exchange type power distribution cabinet

A technology for power distribution cabinets and ventilation hoods, which is applied in the substation/power distribution device shell, substation/switchgear cooling/ventilation, electrical components, etc. Issues such as the safe use of components to achieve the effect of improving ventilation and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

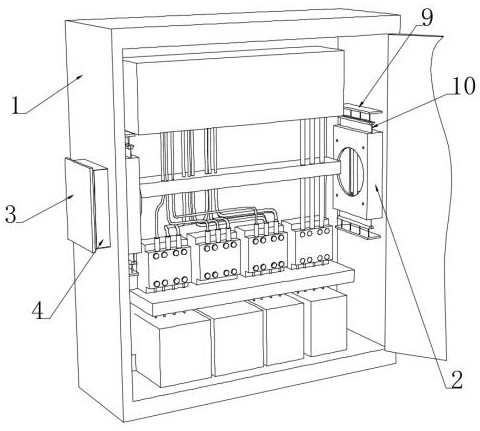

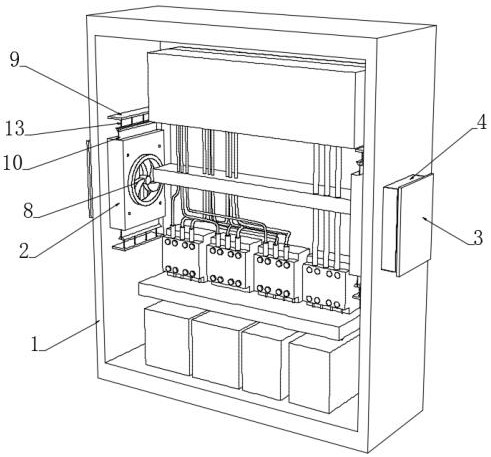

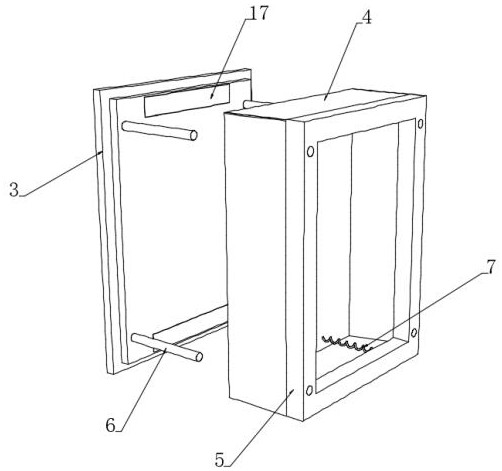

[0045] see Figure 1-4 , a self-ventilating and heat-exchanging power distribution cabinet, including a cabinet body 1, vents are opened on the left and right end walls of the cabinet body 1, and inner ventilation hoods 2 located inside the vents are provided on the opposite inner walls of the cabinet body 1 , the inner side walls of a pair of air vents are all connected with a positioning frame 5, and the outer ends of a pair of positioning frames 5 are provided with an outer dust-proof plate 3, and an elastic dust-proof cloth 4 is passed between the outer dust-proof plate 3 and the positioning frame 5 Convergence, the upper and lower outer end walls of the positioning frame 5 are also fixedly connected with a pair of tension springs 7 connected with the inner walls of the upper and lower ends of the outer dustproof plate 3, and the end walls of the positioning frame 5 are provided with embedded holes for tension spring 7 fixing. Holes, a pair of inner ventilation hoods 2 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com