NCM ternary positive electrode material with lithium vacancy structure on surface

A cathode material and vacancy technology, which is applied in the field of NCM ternary cathode materials, can solve the problems of transition metal element valence state change and crystal structure distortion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step (1) Add 1 g of sodium thiosulfate to 50 mL of acetonitrile, stir and mix evenly at 40° C. for 1 h to obtain a mixed solution;

[0037] Step (2) Add 20 g of the NCM ternary cathode material body into the mixed solution, continue to maintain a stirring temperature of 30° C., and soak for 12 hours to obtain a suspension;

[0038] Step (3) filtering the suspension under reduced pressure to collect solid materials;

[0039] In step (4), the solid material is placed in a tube furnace, and the temperature is controlled in an oxygen atmosphere for heat treatment at 400° C. for 5 hours to obtain an NCM ternary cathode material with a lithium vacancy structure on the surface.

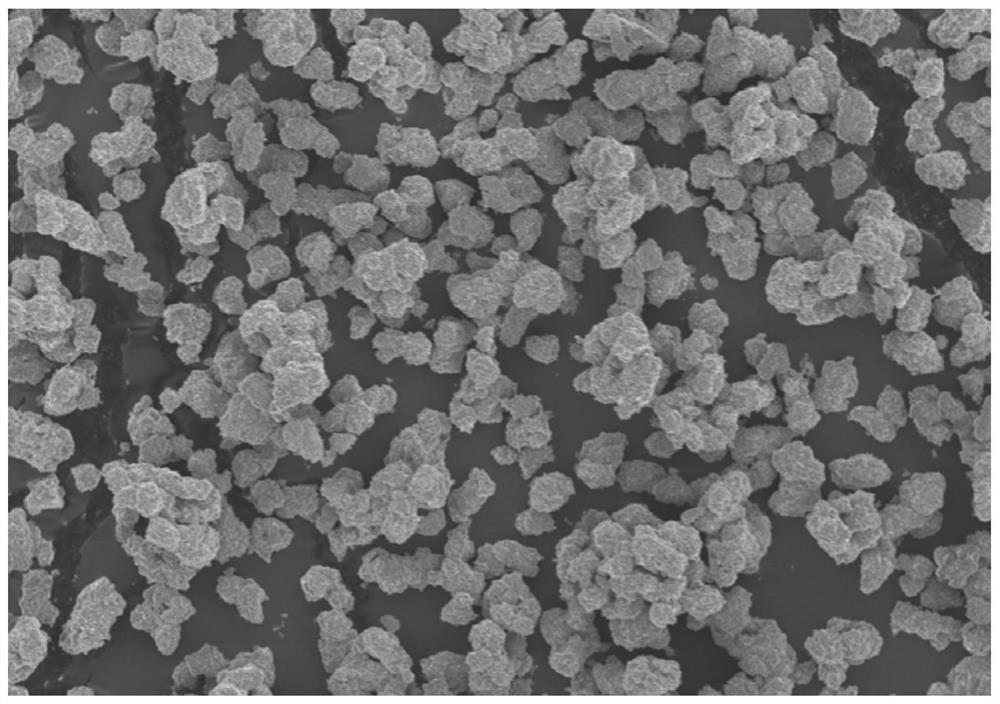

[0040] The scanning electron microscopy results of the final product are as follows figure 1 As shown, it can be seen from the figure that the final product is secondary particles, and the secondary particles are mainly composed of primary particles tightly packed.

[0041] According to the TEM test...

Embodiment 2

[0046] Step (1) Add 2 g of potassium nitrate into 50 mL of ethanol, stir and mix evenly at 30° C. for 1 h to obtain a mixed solution;

[0047] Step (2) Add 20 g of the NCM ternary cathode material body into the mixed solution, continue to maintain a stirring temperature of 40° C., and soak for 18 hours to obtain a suspension;

[0048] Step (3) filtering the suspension under reduced pressure to collect solid materials;

[0049] In step (4), the solid material is placed in a tube furnace, and the temperature is controlled in an oxygen atmosphere for heat treatment at 300° C. for 10 hours to obtain an NCM ternary cathode material with a lithium vacancy structure on the surface.

[0050] The scanning electron microscope results of the final product showed that the final product was secondary particles, and the secondary particles were mainly composed of primary particles closely packed.

[0051] According to the TEM test results, the (003) interplanar spacing of the material incr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Interplanar spacing | aaaaa | aaaaa |

| Interplanar spacing | aaaaa | aaaaa |

| Interplanar spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap