A mining drill pipe male joint and drill pipe with fracture self-locking function

A male joint, self-locking technology, applied in drill pipe, drill pipe, earthwork drilling and other directions, can solve problems such as drill pipe breakage, and achieve the effect of ensuring safety, increasing operation process and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

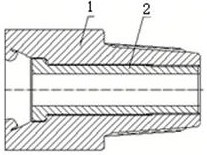

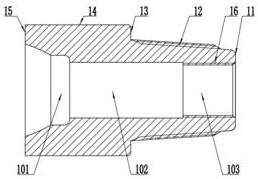

[0040] This embodiment provides a mining drill pipe male joint with fracture self-locking function, such as figure 1 , figure 2 and Figure 4 As shown, the male joint 1 is provided with a central through hole and a self-locking connecting rod 2 is provided in the central through hole.

[0041] The two ends of the male joint 1 are the male joint welding end face 15 and the male joint end face 11 respectively, and the male joint external thread 12 is provided near the male joint end face 11; The joint end face 11 is a first stepped hole 101 , a second stepped hole 102 and a third stepped hole 103 with diameters gradually reduced, and the inner wall of the third stepped hole 103 is provided with a male joint internal thread 16 .

[0042] The self-locking connecting rod 2 includes a tubular connecting rod body 22, the outer wall of one end of the connecting rod body 22 is an annular boss 21, and the outer wall of the other end is an external thread 23 of the self-locking connec...

Embodiment 2

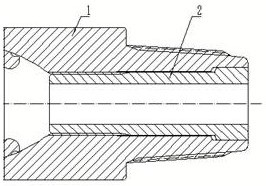

[0050] This embodiment provides a mining drill pipe male joint with fracture self-locking function, such as image 3 and Figure 4 As shown, the male joint 1 is provided with a central through hole and a self-locking connecting rod 2 is provided in the central through hole. The difference between this embodiment and Embodiment 1 is that the central through hole of the male joint is from the end surface 11 of the male joint to the welding end surface 15 of the male joint. hole 103, and the inner wall of the third stepped hole 103 is provided with a male joint internal thread 16; other settings, functions and implementation effects are the same as those in Embodiment 1.

Embodiment 3

[0052] This embodiment provides a mining drill pipe with fracture self-locking function, such as Figures 5 to 10 As shown, it includes a rod body 4 and a male joint 1 and a female joint 3 arranged at both ends of the rod body;

[0053] The female joint 3 is provided with a central through hole, and the two ends of the female joint 3 are respectively a female joint welding end face 33 and a female joint shoulder 31, and a female joint internal thread 37 is provided near the female joint shoulder 31; the female joint internal thread 37 can be connected with The external thread 12 of the male joint is screwed together to realize the threaded connection between the drill pipes; the rod body 4 is provided with a central through hole, and the central through holes of the rod body 4, the male joint 1, the female joint 3 and the self-locking connecting rod 2 are all coaxial.

[0054] Between the female joint welding end face 33 and the female joint shoulder 31 is a cylindrical outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com