Mining drill rod with drill-falling-preventing function

A functional and mining technology, applied in drill pipe, drill pipe, drilling equipment, etc., can solve problems such as drill drop, drill pipe joint fracture, etc., achieve the effect of simple structure, ensure safety, and increase the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

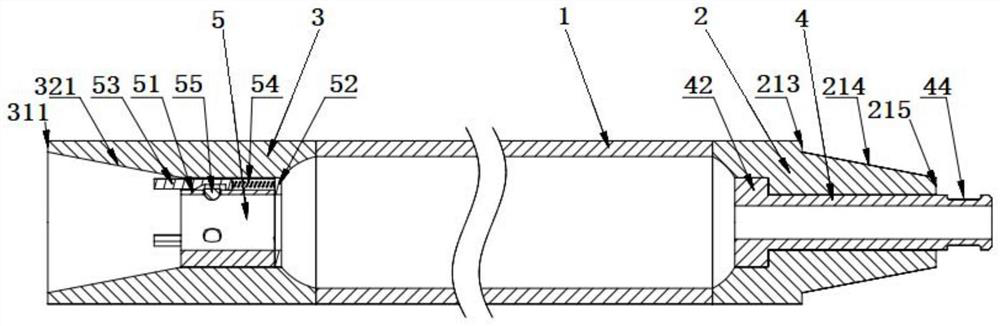

[0048] This embodiment provides a drill pipe for mining with anti-drilling function, such as figure 1 As shown, it includes a rod body 1 , a male joint 2 and a female joint 3 respectively provided at both ends of the rod body 1 , an anti-drop connecting rod 4 provided in the male joint 2 , and a locking mechanism 5 provided in the female joint 3 .

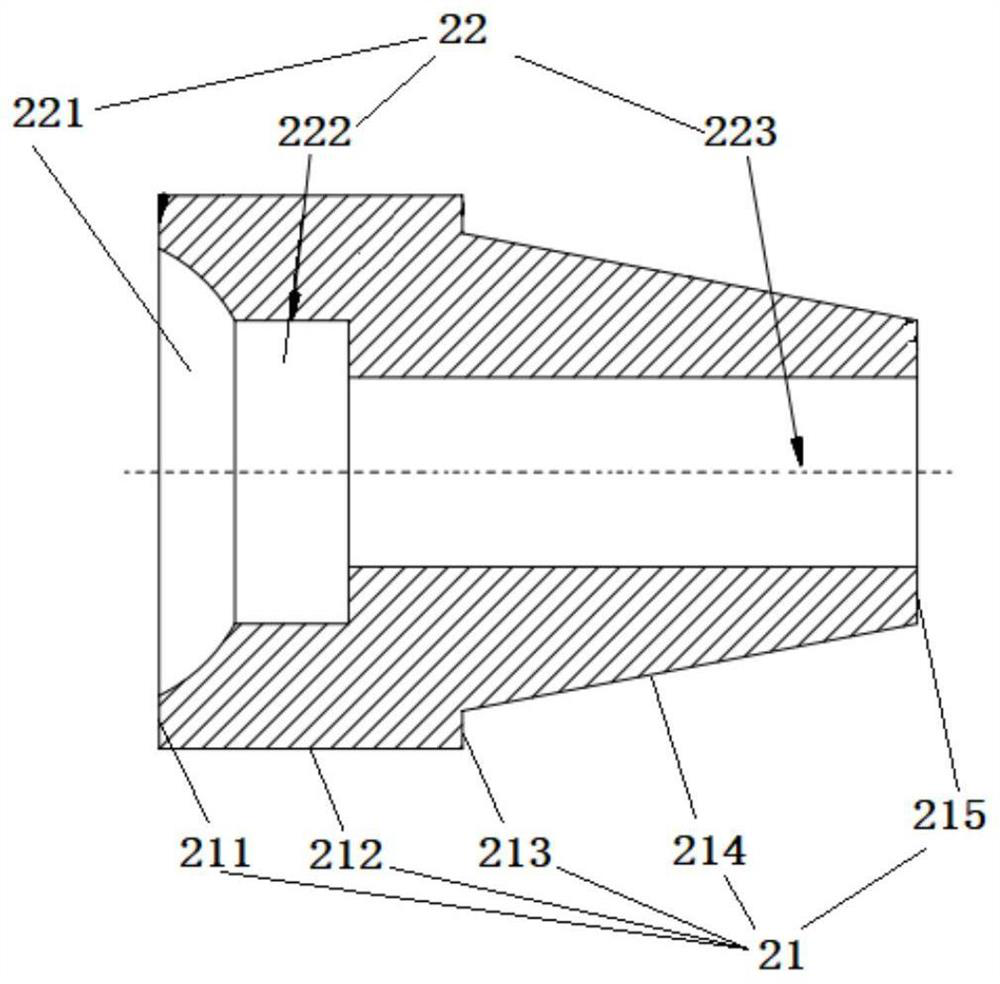

[0049] Such as figure 2 As shown, the male connector 2 includes a male connector body 21 and a male connector central through hole 22. The male connector body 21 includes a male connector welding end surface 211, a male connector columnar outer wall 212, a male connector shoulder 213, and a male connector necking cone arranged in sequence. Segment 214 and the small end surface 215 of the male joint; the central through hole 22 of the male joint includes sequentially arranged: a first male joint through hole 221 close to the welding end face 211 of the male joint, a second male joint through hole 222 and a diameter close to the mal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com