A kind of mine drill pipe with anti-drop drill function

A functional and mining technology, applied in drill pipe, drill pipe, earth-moving drilling, etc., can solve problems such as drill drop and drill pipe joint fracture, and achieve the effect of simple structure, ensuring safety and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

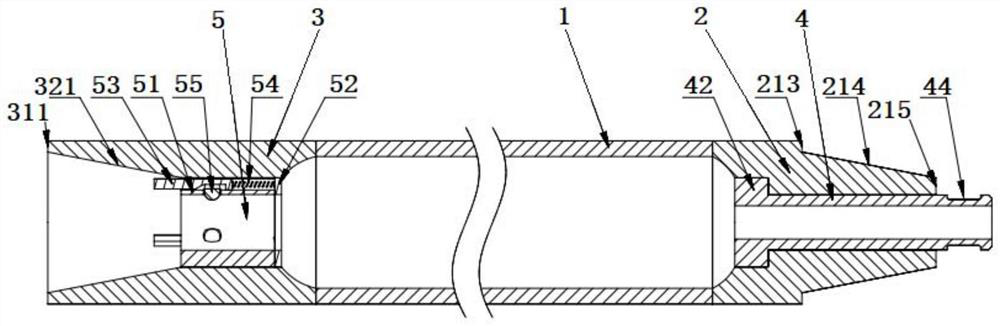

[0048] This embodiment provides a drill pipe for mining with anti-drilling function, such as figure 1 As shown, it includes a rod body 1 , a male joint 2 and a female joint 3 respectively provided at both ends of the rod body 1 , an anti-drop connecting rod 4 provided in the male joint 2 , and a locking mechanism 5 provided in the female joint 3 .

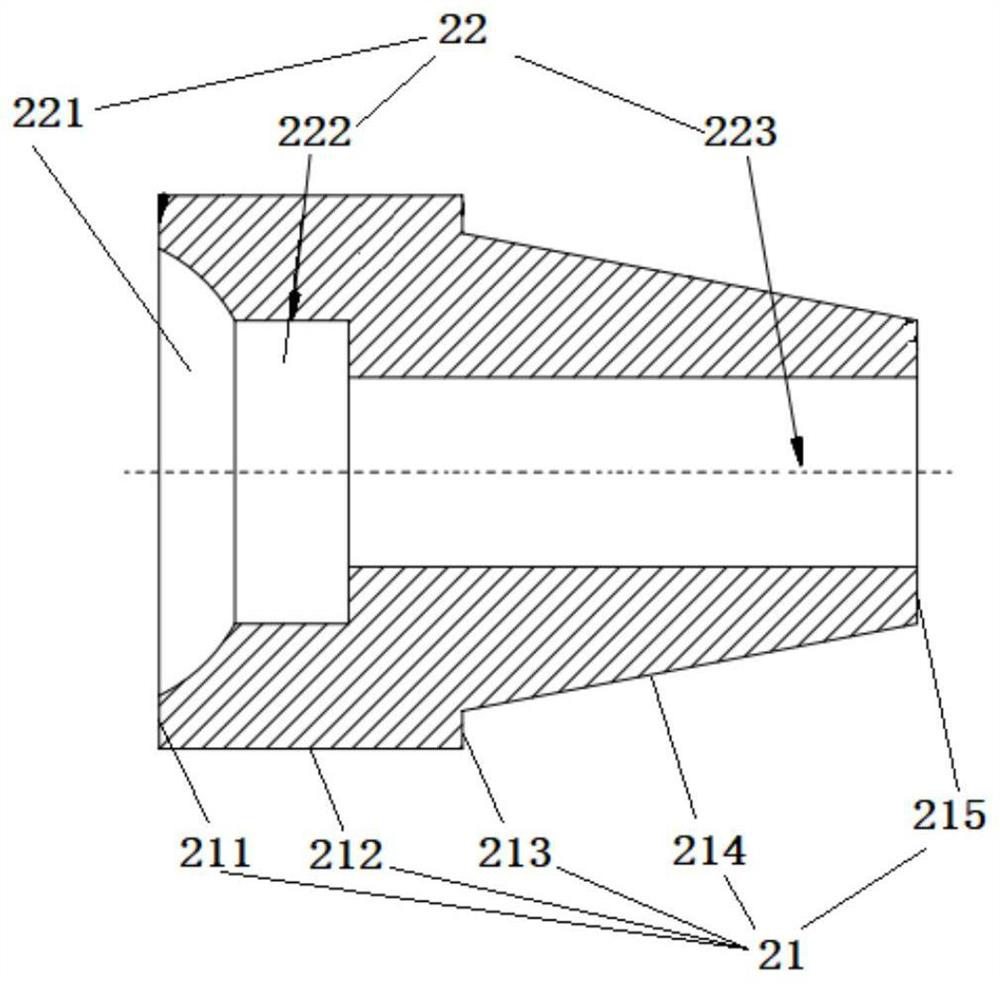

[0049] Such as figure 2 As shown, the male connector 2 includes a male connector body 21 and a male connector central through hole 22. The male connector body 21 includes a male connector welding end surface 211, a male connector columnar outer wall 212, a male connector shoulder 213, and a male connector necking cone arranged in sequence. Segment 214 and the small end surface 215 of the male joint; the central through hole 22 of the male joint includes sequentially arranged: a first male joint through hole 221 close to the welding end face 211 of the male joint, a second male joint through hole 222 and a diameter close to the mal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com