Single-row magazine bullet supporting plate structure

A technology of supporting spring plates and spring plates, which is applied in the direction of ammunition supply, weapon accessories, offensive equipment, etc., can solve the problems of unreliable connection between the support plate and the support spring, easy occurrence of ammunition supply failure, and poor fit, etc., to achieve Simple structure, reliable connection, remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

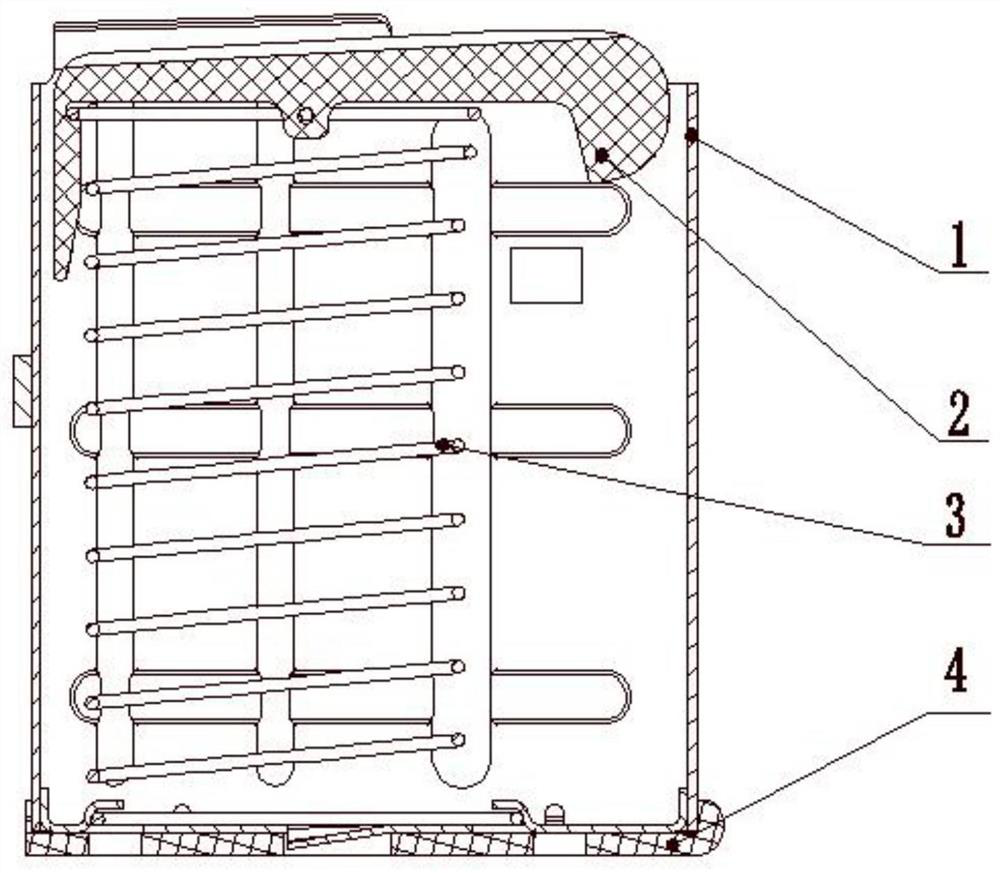

[0017] see figure 1 It is a schematic diagram of the magazine structure, in which: 1-magazine body; 2-support spring; 3-support spring; 4-magazine bottom cover.

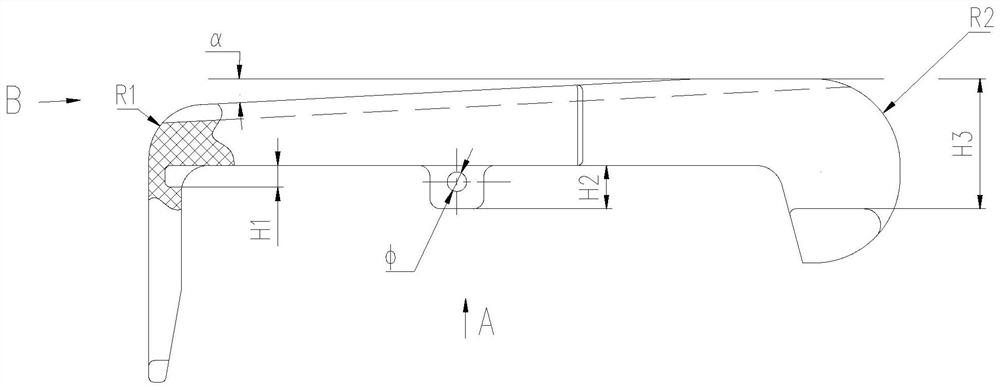

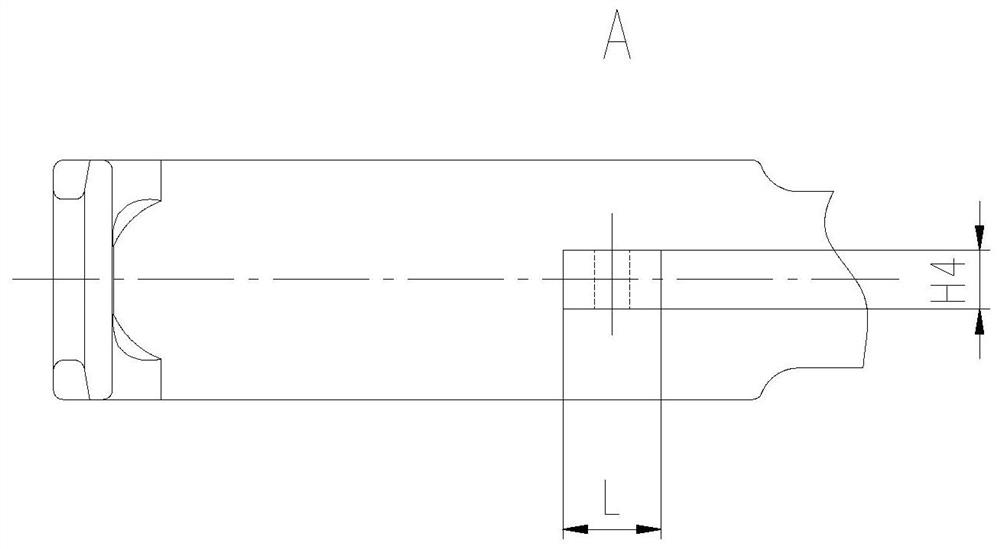

[0018] see Figure 2-Figure 4 , which is a single-row magazine support plate structure, including a support plate body, the upper end surface of the spring support plate body is a slope with a high front and a low rear, and the middle part of the upper end surface of the spring support plate body is longitudinally provided with The circular arc groove is used to cooperate with the surface of the bullet to form surface contact; the lower end surface of the support plate body is a plane, which is used to cooperate with the support spring; the front end of the support plate body extends downward and forms an arc Head, the rear end of the spring supporting plate body is provided with a limiting plate extending downward, the chamfering between the limiting plate and the outer surface of the spring supporting plate body f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com